The modern digital era has allowed for amazing developments in computer science, automation and office organisation. Eldir System has many years of experience in the industry, which has enabled the company to create REFRAMANAGER, an innovative management platform for maintenance that is specifically for use in cement plants.

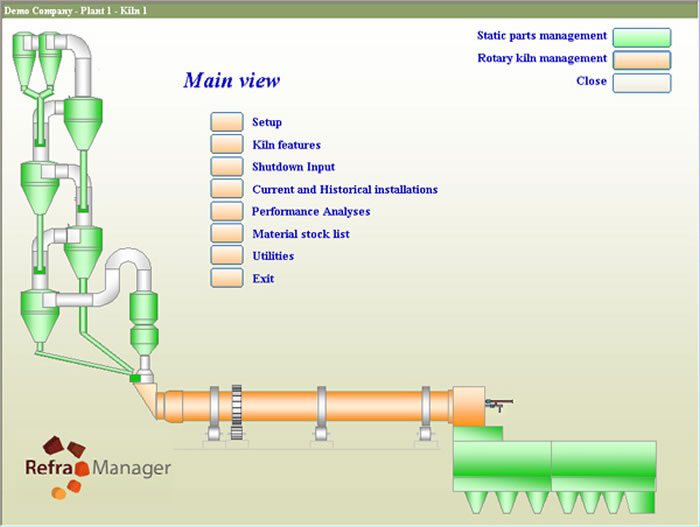

The goal was to create a system that could translate all necessary data into a software platform: for example, all of the significant data that has to be collected and assessed during the planning of maintenance services on kilns and static parts. All plant visuals can be drawn upon with a simple click of the mouse, eliminating the need for piles of paper, drawings, files and Excel documents.

The REFRAMANAGER software system uses a single database, which can also be centralised, and this allows the management of all historical data, organized by rotary kilns and static parts and broken down into company, factory, machine and model. The software allows the user constant access to all the technical details relating to each operation by sequential numbering and archiving of photographs, technical details, drawings, reports and data sheets, as well as all details of the materials used and the operating costs.

Rotary kiln maintenance

Information regarding the company, the business group, the plant and the machine is organised into a tree structure. A special table will allow the user to view the list of companies divided into groups. Each group will correspond to a list of plants and thereby to the data sheet of the kiln being analysed.

The user may enter identifying details of the machine such as the diameter of the kilns, the length, the positioning of the rings and the girth gear by filling out an interactive table that schematically represents the kiln. The user must then complete a datasheet providing descriptions of the various zones of the kiln (e.g. kiln outlet, lower transition zone, burning zone, high transition zone and the drying zone).

A specially designed archive will allow the user to manage the complete list of suppliers and quality of refractory bricks used according to a particular format (ISO, VDZ, formless and other designs). The data sheet, detailing the product, size, composition, number of bricks used and the breakdown by category (e.g. alumina bricks and basic bricks), including costs expressed in local currency and the specific weight and density, can be easily viewed. Each entry in the list will allow the possibility of inserting an attachment (e.g. drawings, photographs and technical details).

A step-by-step process allows the user to enter the type of maintenance, commonly referred to as ‘shutdown insert’. A click on the appropriate small table of shutdowns will allow the user to choose the type of maintenance being carried out. For example, the F-type is used for the replacement of refractory and an S-type shutdown will allow the user to identify issues not related to the refractory, but to other aspects of machine replacement external components (such as electric motors, fans and mechanical interventions).

The P-type shutdown, however will allow a company to arrange for scheduled maintenance in the future so that all minor details will be taken into account.

Following the selection of the type of refractory brick, the user may choose the amount of product from the list (sorted according to brand and quality) based on how much refractory lining is required. All quantities will be calculated automatically and displayed graphically, enabling the user to view the representative table of the kiln with the exact positioning of the coating installed. Each product will be associated with a particular colour and texture, so that it may be identified quickly and easily.

When completing the registration of the operation, the details of clinker production until the day of the shutdown can be inserted, as well as the total number of kiln operating hours. This will allow the user to extract the data required for the calculation of specific consumption. During the maintenance operation, the user can enter a single brick or a complete cladding. Furthermore, the percentage of unused material or material scarp that has been discarded for various reasons may be calculated.

Preheater maintenance

After recording the maintenance required for the rotary kiln, the static parts if the plant will be addressed; for example, the cyclones in the preheater tower. A tree chart is customised to include all the technical details, which are organised using a system of nodes and sub-nodes, allowing the user to visualise the entire sequence of the components that make up the preheater tower.

For example during the analysis of the stage-1 cyclone of the preheater tower, key parts of the equipment are divided into separate categories, including the inlet pipe, the upper part, the cylindrical part, the conical part and the drain. Following this, operational details can be directly inserted into the appropriate category with a serial number that will form part of a historical list – everything can then be viewed via a simple click on the system diagram.

For example, the user can click on the node labelled ‘cylindrical part’ and enter details such as the size of the first layer of insulation (Layer 1) and the working lining of refractory bricks (Working Layer). All the accessories that have to be used (e.g. the number of anchors) are recorded and the user will have the opportunity to view the technical drawings, the measurements, the materials, the unit cost, the total weight and the total number of components used.

Once the archive data is compiled, all the details and the documents recorded at the time a company planned and executed its maintenance are made available with an instant display (there is also the option of printing all the reports).

REFRAMANGER is designed for cement plant users, however is also ideal for companies wanting to manage their refractories in rotary kilns only. The software is flexible in that the Static Parts part can be deactivated and can very effectively be used for managing either shaped (brick) or unshaped (castable or monolithic) refractory lined rotary kilns.

Data management

To complete the refractory management software the company offers a feature called ‘Global Reports’ that relates to specific criteria available in both a tabular and graphic form. The software enables a company to:

Analyse all of its systems.

Calculate specific consumption.

Assess costs.

Consult the quality control archives.

Visualise where and how much refractory the company has installed.

Compare the data from a single plant or a group of plants.

Perform a complete analysis for the entire company.

It is possible to compare the last four years of operation and evaluate averages for each category. For example, the company could observe and recall the use of a single product by searching where a certain type of refractory has been installed. The specific consumption of a single brick may then be analysed. Alternatively, the product can be categorised (e.g. alumina bricks, basic bricks or other materials) and data translated into graphs that detail cost, quality, supplier and weight.

Many types of data can be managed with REFRAMANAGER. For this reason, Eldir System offers a trial period during which a company may test the software. Personnel are available to assist in the installation, implementation and operation of the management system and to pay attention to the suggestions and experiences of cement plant workers that will allow for further improvement of the software.

Operating notes

The REFRAMANAGER platform can be installed and used in three different ways:

Local use/local machine: it can be installed on a personal computer for a single user and is used only be a single client.

Corporate network use/intranet configuration: support is installed through the use of a Microsoft SQL database prepared on the central server. Each user can install an operating license onto their personal computers and will then be directly connected to the central server of the company. In this way, all parameters and data will be centralised and all users can gain access to it.

In-cloud use: a dedicated space on a server owned by Eldir System. Users will be able to use the software anywhere in the world using a specific link and an active internet connection. Total security, privacy and data protection is guaranteed, through highly advanced software and hardware tools for access control and data security.

The type of installation choice will dictate supply conditions and all three options are interchangeable. For instances, if the user chooses the local use option, in the future they can switch to corporate network or in-cloud options.

The REFRAMANAGER software allows for constant, comprehensive and highly detailed monitoring of a company’s production facilities through a centralised and customised database. Above all, the technological innovation consists of, apart from the fact that it is a powerful computer tool, in having created a fundamental aid in the archiving and recording of documents which, notoriously, most of the time in the past, were left in the bottom of a drawer or were only to found in the minds of highly skilled engineers with many years of experience. Today with REFRAMANAGER everything will be stored in the digital memory of your corporate server, and archives will remain unlimited in time, and also available, to be consulted by everyone in seconds. All this may be done with very a low investment outlay, resulting in enormous time and cost savings.