A Growing Awareness of Electrical Bearing Damage

When Electro Static Technology launched the AEGIS® Shaft Grounding Ring product line in 2004, most engineers had never heard of electrical bearing damage. Both VFD manufacturers and motor manufacturers vehemently denied that their products were to blame for the pitting, frosting, or fluting of motor bearings. The engineers who designed motor systems driven by VFDs seldom saw or had to deal with the problems of bearing damage. And the maintenance people who routinely replaced damaged bearings assumed such damage was either normal or unpreventable.

Today, 10 years on, most design or process engineers are aware of the problem and its causes, and a growing number of maintenance personnel have learned how to prevent electrical bearing damage using AEGIS® Rings.

Yet the success of AEGIS Rings has prompted a spate of products that supposedly provide the same or better protection of motor bearings against electrical bearing damage. Most, however, provide only limited protection against such damage because they wear out quickly (leaving motor bearings unprotected), have only limited effectiveness due to their design, or are ineffective in the presence of contaminants.

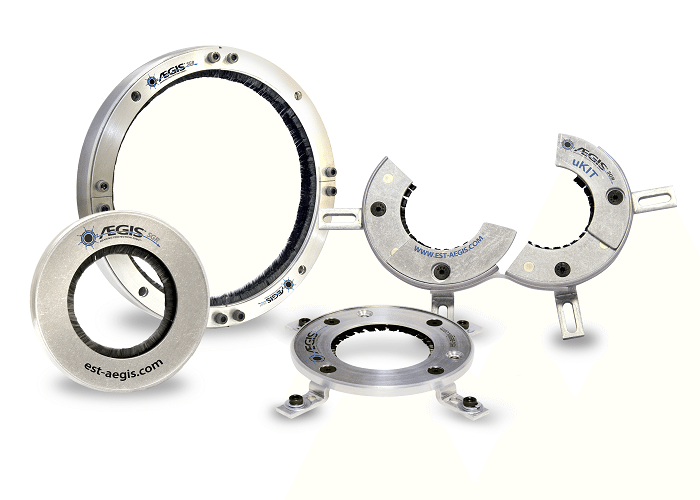

As a result of their unique design and construction, only AEGIS Rings encircle the motor shaft with full 360° circumferential brushes that provide thousands of contact points for unmatched current-carrying capability. The ring’s proprietary conductive microfiber brushes are specially engineered to flex without breaking (to last for the L10 life of the bearings) and to work in the presence of oil, grease, dust, or other contaminants.

And, due to their revolutionary Nanogap Technology, only AEGIS® Rings work regardless of whether they are in physical contact with the motor shaft or merely in close proximity to it.

Finally, no other shaft grounding technology has been proven effective in providing long-term bearing protection in over a million installations worldwide. So, if you’re aware of VFD-induced bearing damage, protect your motors with the most effective and cost-effective shaft grounding technology available — AEGIS® Bearing Protection Rings.

I NEED QUOTE FOR AEGIS SHAFT GROUNDING RINGS/BEARING PROTECTION RINGS FOR THE FOLLOWING TYPE OF MOTORS

1.WEG 220KW,355M/L MOTOR 1490RPM,525V by 2

2.WEG 185KW,315S/M MOTOR 1490 RPM,525 VAC by 1

3.WEG 75KW,280S/M MOTOR 985RPM,525VAC by 1

I NEED QUOTE FOR AEGIS SHAFT GROUNDING RINGS/BEARING PROTECTION RINGS FOR THE FOLLOWING TYPE OF MOTORS

1.WEG 220KW,355M/L MOTOR 1490RPM,525V BY 2

2.WEG 185KW,315S/M MOTOR 1490 RPM,525 VAC BY 1

3.WEG 75KW,280S/M MOTOR 985RPM,525VAC BY1