Dr. Lucà & Partner is a technology driven company in the field of thermally manufactured insulating porous construction materials and other construction materials as blocks and wall elements.

Core competence is the manufacturing of worldwide unique biotechnological additives under the brand LithoFoam® as well as machinery up to a daily capacity of 400 cubic meters. Plants with higher capacities will be provided through a highly reputed German cooperation partners.

The brand LithoPore®, a German advanced cellular lightweight concrete technology has a symbol of sustainable construction materials with high quality and density range of 70-1600 kg/m3. It is produced by initially making a slurry of Cement + Fly ash or Sand + Water, which is further mixed with the addition of pre-formed stable foam in an unique Foamed concrete mixer under ambient conditions. The mixture is either poured or pumped into assembled moulds of blocks or form-work of reinforced structural elements or poured onto flat roofs or voids for thermal insulation or filling. The foam imparts free flowing characteristics to this slurry due to ball bearing effect of foam bubbles enabling it to easily flow into all corners and compact by itself in the moulds/forms without requiring any kind of vibration or compaction.

The trade name LithoFoam includes several foaming agent types. LithoFoam foaming agents are protein based with enzymatic active components, developed especially for the building material industry. Diluted in water and processed in a foam generator with compressed air and it produces very fine and stable high quality foam.

It has several advantages;

- Improved silicone oil resistance, frost resistance, anti bacterial properties (effective against mildew)

- Specific foaming agent for roofing, flooring, block production, cast in situ walls

- Foam gross density adjustable 20-180 kg/m³

- High Efficiency: 1 kg foaming agent produces up to 2000 Liters of foam

- Concrete gross density adjustable 2000-200 kg/m³

- Neutral, technical odor

- Highly active proteins due to nanotechnology

- Very competitive prices

Various applications of LithoPore Concrete are:

- Pre cast Blocks / Panels– For Internal & External walls in a building. Due to its lightweight and bigger size, the dead weight of the building is reduced and faster in construction. It is very much suitable for Earth quake prone areas. Due to its thermal efficiency, it protects the building from heat and cold and so lower energy consumption for Air Conditioner or Heater.

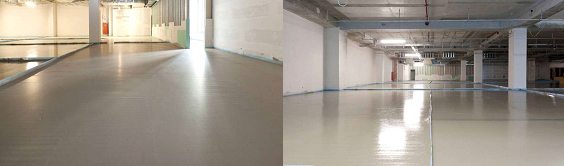

- Insulation Screeds – For thermal and sound insulation layers on the floors and roofs in a building to reduce the temperature from outside to inside of the building.

- Cast-in-situ applications – Due to its advantage of producing the concrete at any place using the mobile concrete mixing unit, LithoPore Concrete can be produced on the construction site and pumped directly for screeding, direct casting of walls using formworks, sunken filling, etc.

- Sunken or Cavity Filling – Because of free flowing capability and very less weight of this concrete, it can be used to fill any sunken or cavity portions inside the building or outside.

They are currently looking for interested distributors across Africa.

Contacts;

Dr. Lucà & Partner Ingenieurkontor GmbH

Sivaram Kumar

[email protected]

www.dr-luca.com