All electrical systems have the potential to cause harm. Human beings are more conductive than the earth which means if there is no other easy path, electricity will try to flow through our bodies.

The voltage of the electricity and the available electrical current in regular businesses and homes has enough power to cause death by electrocution. Even changing a light bulb without unplugging the lamp can be hazardous because coming in contact with the ‘hot’, ‘energized’ or ‘live’ part of the socket could kill a person. It is therefore important to work safely with or near electricity.

The following are some of the factors that ensure not only safety when dealing with electrical systems but also reliability of the installed system.

Know your system

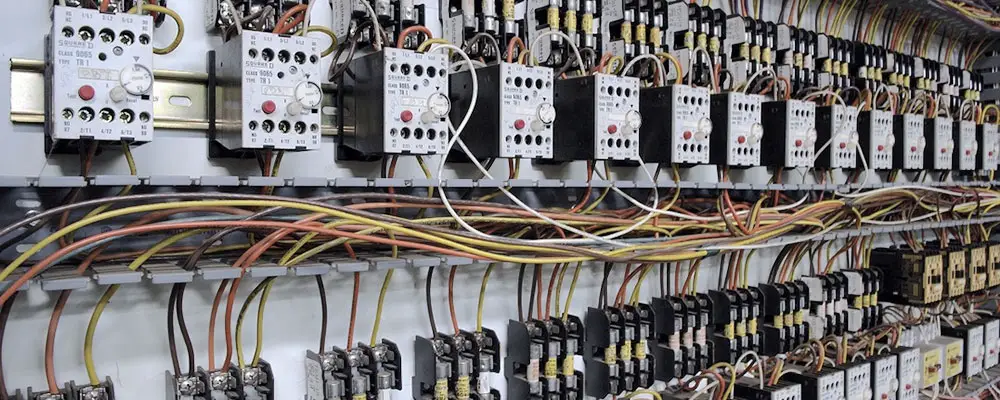

The first key to knowing your electrical system is an accurate and up-to-date one-line of the electrical system. With the facilities of today, which integrate multiple supplies and voltage systems, knowing how the system components are integrated together is key to the safety and reliability of your electrical system.

Many facilities have added, removed and remodeled over the years, so that no one really knows what their electrical system looks like today. Knowing how the various systems interconnect is critical to the operation, maintenance and trouble shooting of the system.

Know your equipment

Know your equipment

It may seem too simple, but the first step in knowing any piece of equipment is to read the manual. Keep in mind that equipment that may look the same may not operate the same. Systems may also vary depending on the application and installation. Whether it is equipment you are operating or equipment you are installing, spending time with the products’ documentation can save you many headaches.

Additionally, according to Mr. Gary Barlow of Switch gear Limited, a leading manufacturer of switchboards, one should always make sure not to install the cheapest product as it can create havoc for you and the property. The best is to ensure that the products are of highest quality and suits your requirements.

This can be made easier by buying from reputable companies. Mr. Anjali Mediratta, Director at Polyphase Systems Limited in Kenya mentions that, finding reputable companies to buy electrical equipment from is the first step in getting genuine products. “This is because these companies carry recognizable brands that have been tried and tested,” he adds.

Preventive maintenance

Preventive maintenance is often ignored and considered too expensive to implement. In reality, it is a valuable investment that is measurable. Preventive maintenance can help avoid equipment failure, alleviate repair and replacement costs, and increase safety for personnel. It should not be treated as an unnecessary investment.

An effective preventive- and proactive-maintenance program should take into consideration safety, the age of the equipment, operating environment, and the critical of the asset. If infrared scanning is the only form of preventive-maintenance approach that’s been employed, equipment reliability and safety have been compromised. That type of situation should be of great concern to plant managers, maintenance managers, technicians, and other employees.

Safety first

No amount of speed or pressure to get things done should make employees cut corners when it comes to safety measures. According to Mr. Mohammed Anjarwalla, Director of Regional Electricals in Kenya electricity is one of the most delicate things a property owner has to deals with on a daily basis; therefore, cutting corners leads to costly and often deadly errors.

It is advisable to always lock-out, tag-out and de-energize electrical system equipment before working on it. Use a method of procedure as a check list and wear the appropriate personal protective equipment for the job. Put as much physical distance between people and energized equipment as possible. Keep safety at the forefront of your mind, always watch for others, and don’t be complacent.

Furthermore, the technician performing periodic maintenance and service of electrical equipment should have a thorough understanding of the electrical field and should be trained and familiar with the equipment and systems they are working on. Mr. NischalGajjar the Managing director at Power Controls Limited in Kenya adds that, qualified and trained personnel understand the construction and operation of equipment and installations, therefore they not only ensure efficiency of the system, but they also have safety training to recognize and avoid the hazards involved.