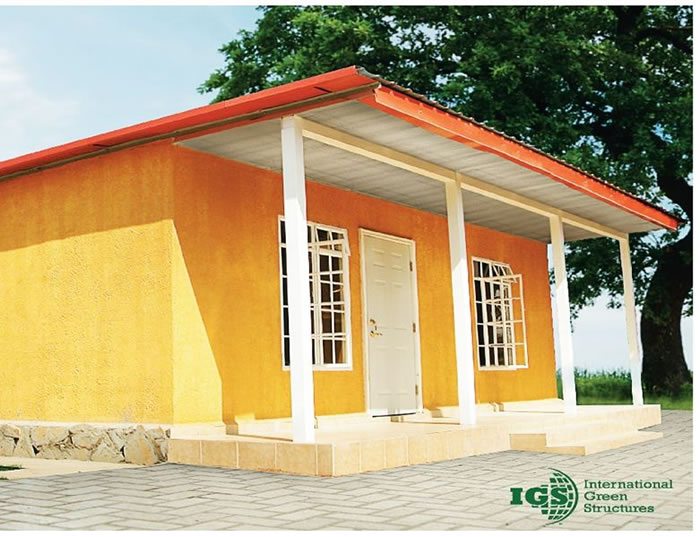

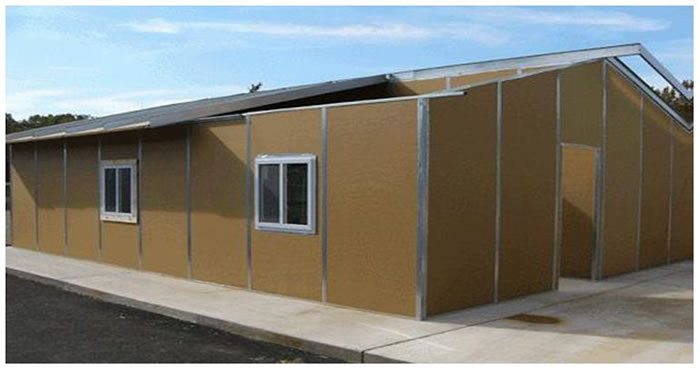

International Green Structures (IGS) is providing solutions for the global housing crisis. To meet this need, IGS has taken a renewable resource to manufacture Compressed Agriculture Fiber (CAF) Panels and combines them with a pre-engineered framing system, resulting in IGStructures. Permanent or temporary, IGStructures are durable, affordable, and can be built significantly faster than traditional building methods. They are culturally adaptable and ideal for homes, schools, healthcare facilities, large-scale accommodations, remote worker sites, and humanitarian needs.

Having an in-country manufacturing facility, they provide an opportunity for rice and wheat farmers to earn a second income stream, promoting sustainability, greater agricultural food security and increasing jobs. All their structures and building solutions are easy to construct or assemble creating jobs, training and certifications for youth in manufacturing, construction, and secondary finishing products using 95% local labor with obvious flow-on economic benefits. The outcome is high quality, very affordable and extremely durable structures and building products that can be erected in a matter of day/weeks rather than months for either one story structures or the internal walls of high rise buildings.

The technology been introduced in other parts of Africa, such as Kenya, Ghana and in Uganda, where the President of Uganda, His Excellency Hon. Yoweri Museveni and the Uganda People’s Defense Force Engineering Brigade of Uganda commissioned the IGS prototype in February 2013.They are currently based in Maryland and has an office in Nairobi, Kenya where they run an operational base for East Africa.

Julius Kamau Nyoike, President of IGS Kenya LLC, advices ideal buyers, Construction Companies and Developers who want to build faster, with durable, green, sustainable building products, to consider their products given that IGStructures and Internal Wall Systems are pre-engineered, providing easy, convenient transportation and fast assembly in days, not months and provide a no waste construction site. All these factors reduce the cost of production and allow for secondary finishing items (electrical, plumbing and finishing) to be purchased locally, offering an affordable, appropriate alternative for the building and construction industry.

Nyoike also commented on the emerging trend with regard to pre-engineered or prefab buildings that, “since the process is faster than traditional methods, using local materials and labor to produce green, durable structures, construction companies and developers are shifting to the new mode of construction where they will be able to complete builds faster with culturally adaptable, green building materials allowing banks to increase the amount of-mortgage loans they offer.”

IGS has participated in several exhibitions including; Shelter Afrique, Abidjan Cote d’Ivoire in June 2014, Panel Participation on Corporate Council in Africa Infrastructure Conference – DC October 2014. They are currently looking forward to their participation on the upcoming Initiative for Global Development Frontier 100 Forum in NYC this October 2014.

Contributor:

International Green Structures

Julius Kamau Nyoike,

President of IGS Kenya LLC