The Concrete Manufacturers Association NPC (CMA) is the primary custodian of Africa’s precast concrete industry. Over its 43 year history, the CMA has evolved from its origins as a masonry association into a body which promotes the full scope of today’s precast concrete line up.

Membership is open to all precast concrete manufacturers, and members fit into either or both of the Association’s two operational pillars, Precast Building and Precast Infrastructure, depending on their product mix. Although membership has always been open to companies throughout Africa, the Association now actively recruits among African precast concrete manufacturers.

Besides South Africa, the current membership roll comprises companies from Botswana, Namibia, Zambia and Zimbabwe, in addition to some from Europe and Asia looking to enter Africa’s lucrative market.

Besides access to the industrial know-how of the CMA’s panel of experts, there are numerous benefits to membership.

These include:

• Being part of an association brand which is widely recognised and respected for setting and maintaining best-practice standards

• Access to industry-specific statistical information

• CMA branding on company stationery, website, packaging and products

• Participation in the prestigious CMA Awards for Excellence competition

• Listing on the CMA website

• Membership discounts on seminars and educational courses

• Participation in setting national standards for the industry

• Access to best-product design and manufacturing processes

• Opportunities to feature innovative precast concrete projects in the CMA’s magazine, Precast

• Client referrals

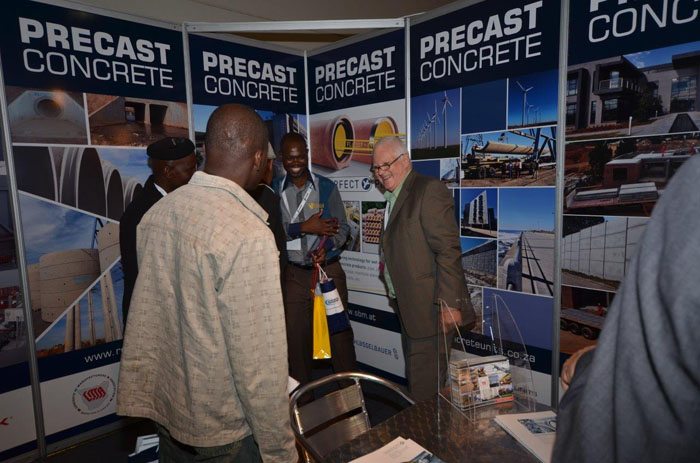

• Participation in and product displays at exhibitions.

For CMA membership purposes, precast concrete is defined as a concrete product cast in a re-usable mould or form, cured in a controlled environment, transported to site and lifted into position. There are five membership categories: producer; non-producer; associate; contractor; and cement producers.

Membership is granted on the basis of the following:

• Production takes place in a purpose-built manufacturing facility

• A quality assurance system is in place

• Occupational, health and safety (OHS) procedures are in use

• Technical and engineering competence

• Financial stability

• Environmental compliance.

The CMA’s promotional activities target architects, engineers, developers, contractors and property owners and the pooled knowledge and expertise of its members fosters an environment which encourages the development of innovative, environmentally and community-friendly products.

Members are encouraged to hold accredited product certification such as the relevant SANS standard or to manufacture to specifications laid down by the CMA.

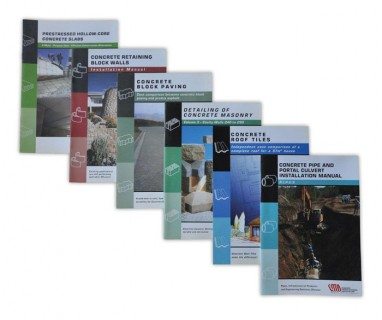

The CMA has published numerous manuals, brochures and audio visuals on the practical application of precast concrete and this material is available to members at a nominal charge. It also runs refresher courses and holds seminars to introduce new technology and methodology, often featuring overseas experts.

Over the past 15 years the CMA has virtually re-written, amended or upgraded nearly all South Africa’s national standards on precast concrete. These standards focus on both the manufacture and application of precast concrete.The preparation of new and the revision of existing standards is undertaken in collaboration with bodies such as The South African Bureau of Standards and Agrément South Africa. The Association is currently working with the SABS on the revision of four national standards.

CMA director, Wally Armstrong, says the main challenge facing the CMA is to convince professionals and specifiers that the products and systems it advocates are of considerable advantage to all concerned i.e. specifiers, industry professionals, and of course, the end-user.

“Our other challenge is to nurture and encourage technical skills and innovation in the manufacture and application of precast concrete industry – to the benefit of all.”