African road authorities are benefitting from the use of Mechanically Stabilised Earth in major construction projects in Africa for applications where, traditionally, concrete options have been dominant.

Through information from Reinforced Earth South Africa Construction Review examines the material. Formed in 1975, Reinforced Earth (Pty) Ltd is part of Group Terre Armee International which operates throughout the world. There are Reinforced Earth® MSE structures in 24 African countries.

The invention

Although the combination of earth and reinforcements is found in nature and in materials and structures (straw in bricks, parts of the Great Wall of China), modern day Mechanically Stabilised Earth was invented by French Architect and engineer Henri Vidal some 50 years ago. He called this new material Terre Armee® in French or Reinforced Earth® in English.

Composite material

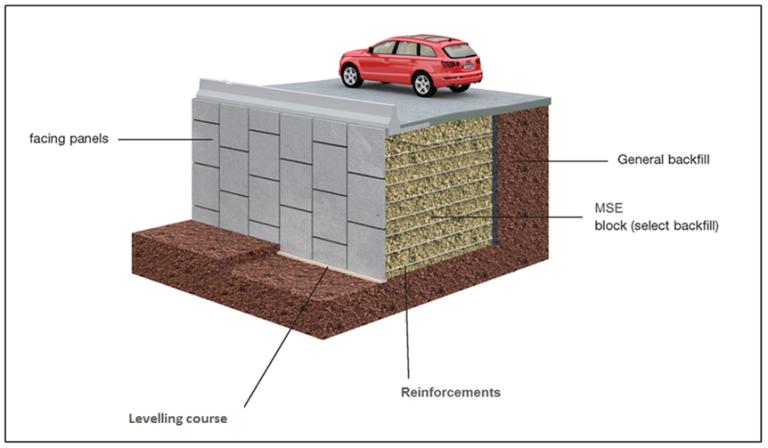

Mechanically Stabilised Earth is the generic name for a composite material comprising a frictional backfill, reinforcements and generally an external cladding.

Advantages

The demand for cost effective construction systems for mega civil engineering projects has highlighted the significance of MSE. Below some of the most important advantages are listed.

- Flexible properties

Whereas chemically stabilised earth produces a rigid structure, mechanically stabilized earth produces a flexible structure. With this feature, it has much the same properties as earth itself and finds application wherever heavy earth moving is involved – roads, railways, bridges, dams, reservoirs, mines, land development, airports, ports and military.

- Beyond battered side slopes

What is worth noting is that earth embankments are no longer limited to battered side slopes. They may be vertical, tired or sloped. If frictional backfill is used and reinforcements are placed correctly in the fill then the external faces may be vertical, sloped or tiered. Such embankments would be clad with elements which are designed to accept local earth loads and protect the embankment from external forces while not hindering the flexibility of the embankment.

- Dealing with limited space

Through utilising MSE approach embankments there is no need for retaining walls in conditions of limited space. This is more relevant in conditions where foundations are poor and rigid retaining walls require special foundation improvement.

- High load bearing capacity

Furthermore, the MSE approach embankment can be designed to accept high loads such as those imparted on to it from bridge decks. In this case concrete abutments may be eliminated.

- Faster construction

Compared to concrete and similar solutions, it takes a shorter time to erect an MSE approach embankment. This is because the pacing item is generally the placement and compaction of the backfill which should not be influenced in any significant way by the placing of the reinforcements and the cladding.

- Specifications and standards

The original concept of MSE is that of a composite material consisting of frictional fill, flexible reinforcements and a flexible cladding.

In order to protect Road Authorities local national generic specifications for MSE should ensure that only cost effective state of the art sustainable MSE solutions which comply with recognized International norms are tendered.Care should be taken when specifying MSE for a particular project. There are differences in various MSE systems for instance:

Differences between MSE with discrete panel cladding and block wall systems

- Segmental concrete panel cladding

Figure 1: MSE with segmental concrete panel cladding

Each panel is positively attached to the reinforcements. The panels are separated one from the other with joints and pads, which absorb vertical settlement and allow the panels to “hang off” the soil reinforcement. The first row of cladding elements is placed on a weak mix concrete levelling course which does not inhibit differential settlement. The pressure on the foundation beneath the cladding elements is consequently less than that beneath the earth fill behind the cladding. Should there be any internal or foundation settlement of the MSE then the panels, which are positively attached to the reinforcements, will settle with the fill and maintain their integrity as shown in Figure 2.

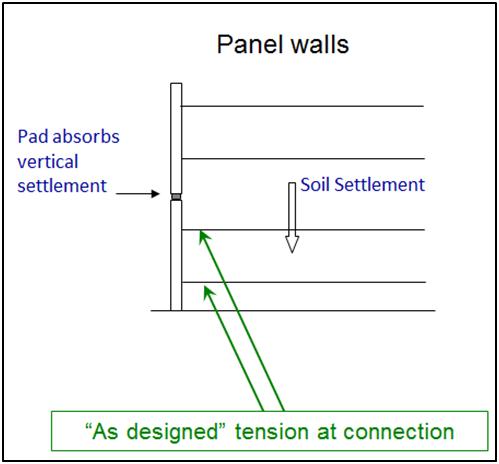

Figure 2: Soil Settlement in MSE Structures

When properly constructed, MSE structures with segmental concrete panels have little risk of facing bulging or deformation due to water. There is no need for a drainage layer at the back of the facing. They also accept seismic deformations and after severe earthquakes remain stable in their new configurations

Segmental panel cladding systems are designed to accommodate considerable differential settlements both during and after construction.

- Modular Concrete Block cladding systems

Figure 3: Modular concrete block wall system

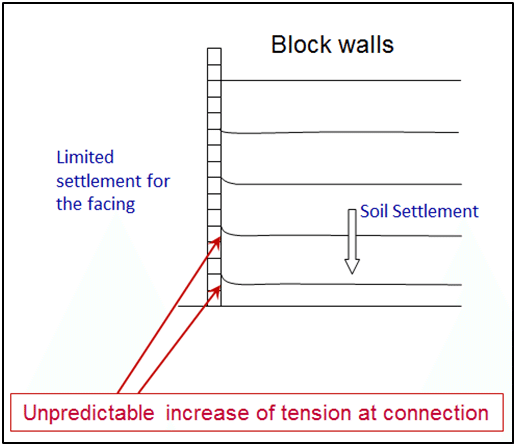

The blocks are founded on a concrete foundation and laid one on top of the other with reinforcing meshes or sheets sandwiched between every 2nd or 3rd layer of blocks. This produces a cladding which has virtually no vertical compressibility, whereas the backfill placed in layers at the back of the blocks is by nature compressible. This can lead to uncontrolled tensions at the connections between blocks and soil reinforcements, as shown in Figure 4 below.

Figure 4: Soil Settlement in a modular concrete block wall system

The ability for block wall systems to accommodate longitudinal differential settlements is also limited.

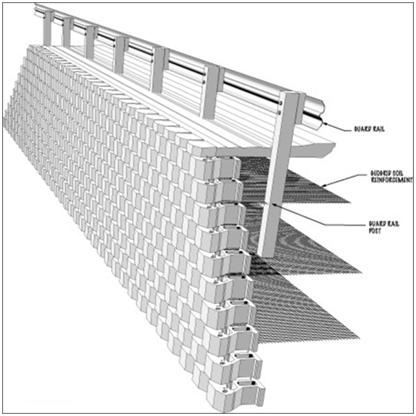

Figure 5: A modular concrete block wall system under construction in Kenya

Particular circumstances will dictate optimum solutions for different situations and designers should understand the limitations of different systems

Concluding remarks

The Terre Armee Group operates in some 50 countries on 5 continents. 50 million square metres of face area has been constructed over a period of 50 years.

Many roads and highways are to be constructed in rural and urban environments throughout Africa.

Reinforced Earth (Pty) Ltd with 40 years of experience in Africa provides a service to owners, consulting engineers and contractors to facilitate the use of MSE for cost effective applications to state of the art standards.

Africa relatively late in the construction of road and rail infrastructure, is well positioned to take advantage of this major 20th century material innovation.