In construction engineering, the pivotal role played by lintels in fortifying structural integrity is undeniable. These horizontal supports, positioned above openings such as doors and windows, serve as critical components in evenly distributing the weight of structures and preventing potential deformities or collapse.

Throughout the historical evolution of construction practices, lintels have remained integral. Dating back to ancient civilizations, from the Egyptians and Greeks to the Romans, these early societies utilised various materials such as stone slabs, wooden beams, and later, stone, concrete, and terracotta to create rudimentary lintels. Their understanding of these supports laid the groundwork for modern construction techniques.

During the Industrial Revolution, significant advancements in manufacturing technology facilitated the production of steel and reinforced concrete lintels. This era marked a turning point, as these materials provided unparalleled strength, durability, and versatility in design, revolutionising construction practices and allowing for the creation of enduring structures.

Historical Context and Evolution

The utilisation of lintels dates back to ancient civilizations, marking a pivotal step in the advancement of engineering techniques. Early civilizations like the Egyptians and Greeks employed rudimentary forms of lintels using stone slabs or wooden beams to bridge gaps and reinforce their architectural creations.

However, it was during the Roman era that the true potential of lintels was realised. Romans ingeniously crafted lintels using materials like stone, concrete, and even terracotta, demonstrating a remarkable understanding of structural engineering. Their mastery in constructing colossal structures such as the iconic aqueducts and amphitheatres showcased the durability and effectiveness of lintels in supporting immense loads.

Fast forward to modern construction techniques, and lintels continue to be indispensable components in building robust and enduring structures. The Industrial Revolution marked a turning point, where advancements in manufacturing technology led to the production of steel and reinforced concrete lintels. These materials revolutionised construction practices, offering superior strength, durability, and flexibility in design.

Materials and Types

In contemporary construction, a diverse range of materials is employed in crafting lintels, each with its own set of characteristics and advantages.

Steel Lintels: Renowned for their exceptional strength and adaptability, steel lintels are favoured for their load-bearing capabilities. Their malleability allows for various shapes and sizes to suit diverse architectural designs. These lintels find extensive use in both residential and commercial constructions due to their ability to span wide openings, offering structural support without compromising on aesthetics. Additionally, their resistance to corrosion makes them ideal for exterior applications, providing enduring support even in harsh climates.

Reinforced Concrete Lintels: Known for their durability and resistance to weathering, reinforced concrete lintels are commonly used in construction. These lintels can be either precast or cast in place, offering flexibility in installation methods. Their integration into architecture involves customization to fit specific load-bearing requirements while maintaining structural stability. Precast concrete lintels, manufactured off-site, provide ease of installation and consistent quality, whereas cast-in-place lintels offer adaptability to intricate architectural designs.

Timber Lintels: Despite being less prevalent in contemporary construction due to concerns regarding decay and fire resistance, timber lintels are still utilised in specific contexts. Their natural aesthetic appeal and thermal properties make them suitable for certain architectural styles or heritage restoration projects. However, their use is limited to smaller spans and interior applications where fire-resistant treatments or protective measures can be implemented.

Composite Lintels: These lintels combine materials such as steel and concrete to harness the strengths of both. The integration of different materials enables the creation of hybrid lintels that offer enhanced load-bearing capacities while addressing specific architectural and structural requirements. Composite lintels exemplify versatility, providing a balanced solution for various construction challenges.

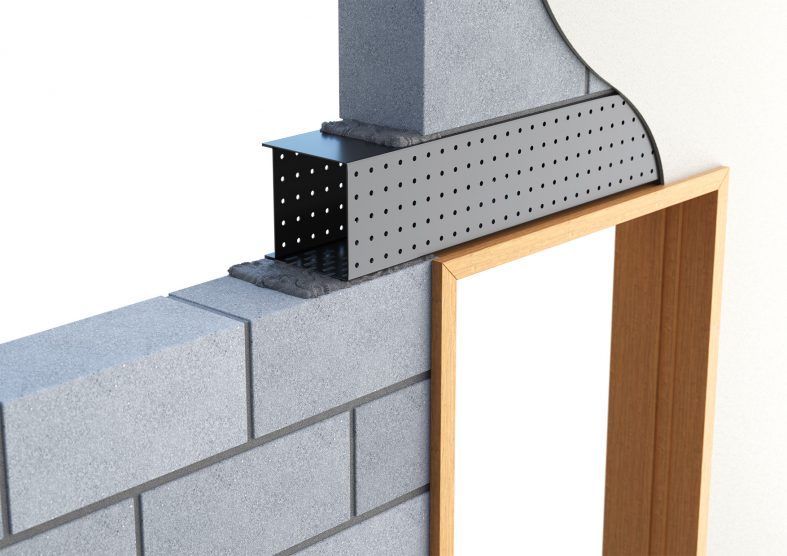

Box Lintels and Cavity Wall Lintels: Box lintels, characterised by their hollow structure, are widely employed in construction, especially in supporting brickwork or stone facades above openings. These lintels, typically made from materials like steel or reinforced concrete, offer robust support while minimising material usage. Cavity wall lintels, designed specifically for cavity wall construction, facilitate the creation of an insulated air gap between inner and outer layers, enhancing thermal efficiency while ensuring structural integrity.

Importance in Ensuring Structural Integrity

The significance of lintels in maintaining structural integrity cannot be overstated. By distributing the weight of the structure above openings, lintels effectively mitigate stress concentrations, preventing sagging or potential failure of walls and openings. Properly installed lintels evenly distribute loads, ensuring that structural components remain stable and secure over time.

The evolution of lintels from rudimentary forms to sophisticated, engineered components reflects the advancement of construction practices throughout history. Their crucial role in ensuring structural stability, combined with advancements in materials and design, cements their place as indispensable elements in modern construction techniques, safeguarding the integrity of architectural marvels around the world.