The construction industry is always improving, using new technologies to make things easier, work faster and improve the quality of projects. One of the big changes is using Computer Numerical Control (CNC) routers. These powerful tools have a lot of benefits, changing the way work is done and helping builders do amazing work. Before talking about the advantages, you should know that these machines come in all shapes, sizes and prices to match what you’re looking for. If you’re not sure which one to get, don’t panic. Many trustworthy companies will let you talk to their pros for free so they can help you pick the best CNC Routers. This way, you’ll get the most value for your money and level up what you can make. Let’s take a look at the top three benefits of using CNC routers in your next big construction project.

Better Accuracy and Consistency

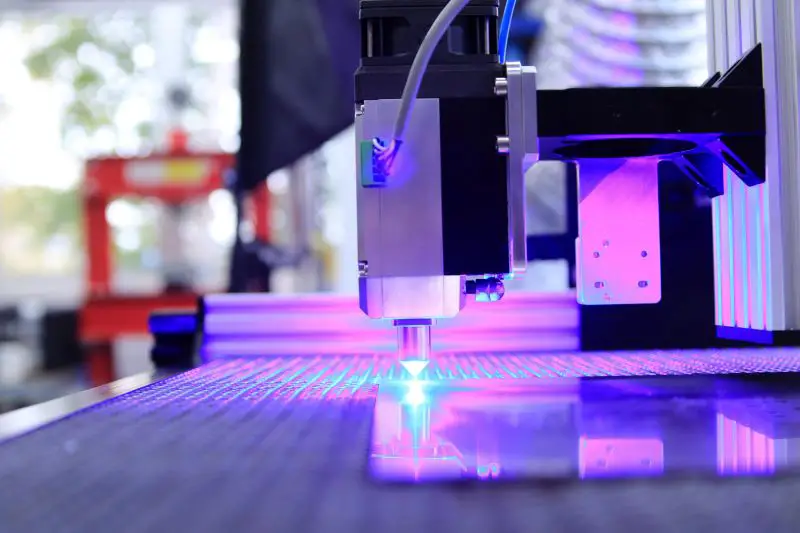

CNC routers remove the chance of human mistakes. Unlike hand cutting, which can often be uneven or wrong, CNC routers cut with extreme accuracy. They follow digital blueprints to carve out detailed patterns and repeat cuts with pinpoint precision every time. This means that everything fits together just right, there’s less need to redo things and you save time and materials.

Also, CNC routers are great for doing the same thing over and over. Once you’ve saved a program, you can use it again easily for other projects, and it’ll give you the exact same results. This reliable performance is really helpful when you have to make lots of parts that are all the same, like house frames, cabinets, or fancy woodwork

Streamlined Fabrication and Quicker Turnaround

CNC routers make the fabrication process a lot faster. They take over jobs that are done over and over, and they make detailed cuts really quickly, which means things get made much quicker. This leads to finishing projects sooner, being able to respond to customers’ needs with lightning speed, and having time to take additional orders.

What’s more, CNC routers let us make things right when we need them, so we don’t have to wait a long time for parts from somewhere else. This lets building teams keep tight control over their timetables and easily adjust if something unexpected happens. Being able to make parts ourselves also means we can change designs at the last minute without a huge hold-up.

Creative Designs and Smart Use of Materials

CNC routers open up endless amounts of design options. They take ideas from the computer and turn them into tangible items, which go beyond old-school limits. They can craft super-detailed patterns and cuts, even a full-size Delorean like in Back to the Future. This precision and scale allow architects, designers, and builders to turn their cool ideas into reality, stretching the limits of what can be built.

These routers are also really good at using materials wisely. They cut extremely accurately, so there’s less waste and better use of materials, which saves money and is kinder to the planet. Plus, these machines can work with all sorts of materials like wood, plastic mixes, plastics, and some metals too, so they’re great for all kinds of building jobs.

Maximize Efficiency with Advanced CNC Technology

To wrap things up, bringing CNC routers into your building projects is a smart move. They make cutting and shaping materials super precise and consistent. Plus, they make the whole making process smoother and lets you be more creative with designs. You can find loads of different CNC routers, from little ones you can put on your workbench to big ones for heavy-duty jobs—so whatever you’re looking for, there’s one that fits your needs and how much you want to spend. You can even pay for them over time, so more builders can use these awesome machines. Using CNC tech puts you ahead in the game, helping you do outstanding work and stand out in the constantly evolving world of construction.