Construction industry has over the years evolved with new technologies. Across many regions of the world, some countries and governments are earnestly calling on more and more businesses and industries to use biomass fuel instead of fossil fuel. In this regard,the former hammer out and implement consented regulations and decrees to encourage the use of biomass energy equipment such as briquettes making machine.

The end use of briquettes is mainly for replacing coal substitution in industrial process heat

applications (steam generation, melting metals, space heating, brick kilns, tea curing, etc) and power generation through gasification of biomass briquettes.

The compaction of loose combustible material for fuel making purposes was a technique used by most civilizations in the past, though the methods used were no more than simple bundling, baling or drying.

Since then there has been widespread use of briquettes made from brown coal, peat and coal fines. The appearance of the de-sulphurization gypsum briquette machine makes the cement construction industry easier to move forward.

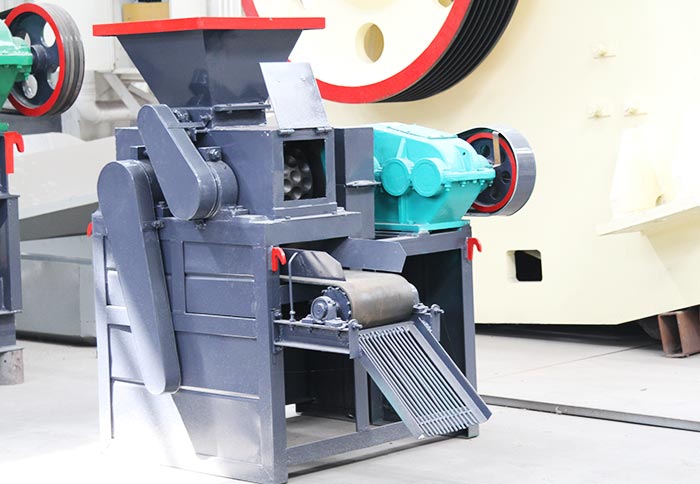

In the construction industry, at least 32 million tons of gypsum materials need to be consumed every year. The most common technique used in de-sulphurization is some form of roller press using only moderate pressure and a binder. This type of plant is also used to make all kinds of non-fuel briquettes from inorganic material such as metal ores. Various binders are used; one of the most common is lignin derived from paper-pulp manufacture.

Benefits

The total investment in briquettes making machine and biomass briquetting plant is projected to dramatically decrease due to their pocket friendly cost. Briquettes making machines are cheaper compared to other biomass material processing equipment with briquetting machine as the dominating machine.

The machine efficiently produces briquettes by compressing the grinded dry waste. These

briquettes are very different from charcoal because they do not have large concentration of

carbonaceous substances and added materials. Compared to fossil fuels , the briquettes produce low net total green house gas emission , because the materials used are already a part of the carbon cycle. Hence this briquettes are good replacement for fossil fuel such as oil or coal.

The briquette press machine also features simple operation and high efficiency on the one hand, and on the other, the construction and running of biomass briquetting plant will demand employment, which to some extent makes full use of laid-off workers.

Compared with wind, solar and nuclear energy resources, biomass briquettes and charcoal and pellets favorably feature safety, low costs, stable performance and easy to handle. In addition to the cost savings associated with reducing the volume of waste compressed briquettes can also be used as a fuel for starting fires or as an insulating materials. There has been a move to the use of briquettes in the developed world, where they are used to heat industrial boilers in order to produce electricity from steam. Biomass Briquettes are a renewable source of energy and avoid fossil carbon to the atmosphere. Biomass briquettes also provide more calorific value/kg and save around 30 to 40% of boiler fuel costs.