International Green Structures (IGS), an American manufacturing, engineering and construction firm that provides affordable building solutions using sustainable and renewable materials, today announced its entry into Kenya. IGS will invest approximately 527 million KSH in its first phase, with longer term plans to build a Sh1.3 billion manufacturing facility in country located in Thika, Kenya.

IGS which becomes the first US Company to enter Kenya after the US-Africa Summit, held early August 2014 in Washington, DC has already spent about KSh130million in market research, technology approval, marketing and prototype units locally.

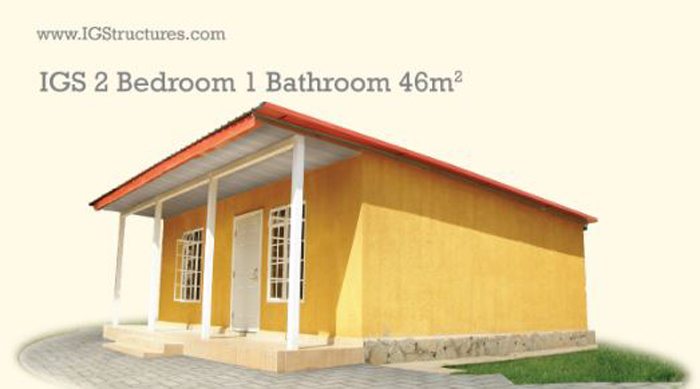

“We are targeting to provide building solutions just under Sh9,000 per square meter by allowing construction companies and developers to culturally adapt the IGStructures for Kenyans in the communities where they live.” said Mike McCarthy, IGS President and CEO of IGS.

Prior to this announcement, IGS held high level discussions with both the government and developers from which it has already received commitments of 3,400 units from the private sector alone.

“There is an overwhelming demand for housing in Kenya and limited supply in the middle and lower market segment giving IGS optimism of great success. IGS’s vision aligns with the Government of Kenya’s Vision 2030, whose long term strategy is to improve livelihoods of Kenyans through facilitation of access to affordable and adequate housing,” said Julius K. Nyoike, President of International Green Structures Kenya Ltd.

The company, which is headquartered in Maryland in the United States, has had a presence in Kenya for over a year, and recently opened a new office in Westlands what will be become its hub for operations in Kenya and across East Africa.

IGS expects to provide a second income to rice and wheat farmers as this is the material used in producing durable panels made from straw, a wasteful by-product of wheat and rice crops that has no potential for fuel or food.

The straw from wheat and rice are up cycled into a Compressed Agricultural Fiber (CAF) Panel. The innovative manufacturing process creates rigid, thermo-set panels that equal or exceed the durability of block and cement or brick. CAF Panels are also incredibly energy efficient with natural thermal and sound attenuating properties, plus they are also fire, water, mold and pest resistant – and harvesting straw has a low-carbon footprint. So not only is this a green product – it is, in many ways, a healthier, sustainable product to traditional building materials.

“Our goal at IGS, is to provide environmentally-sustainable structures that can be shipped easily from the manufacturing facility and assembled and under roof in a matter of days, using local labour. IGStructures meet national and international building codes and are KEBS certified,” said McCarthy.

Because of its flexible technology, IGS can create a variety of IGStructures that are easily expandable and accommodate a variety of sizes and designs – from residential housing to commercial and institutional structures.

Following its entry into Kenya, IGS expects to create over 4000 direct and indirect jobs by end of 2015 assuming an uptake of all its products get constructed. “We target to produce 3000 IGStructures in our first phase which with expansion of production lines will increase capacity to about 12,000 units per year,” said Nyoike.

The company is also focusing on non-profit organizations working in Kenya to deliver homes for refugees and IDP’s (Internally Displace People) across Africa.

Leave a Reply