Dense rain forest and heavy rainfall present huge challenges to the road engineers of the Democratic Republic of Congo.Generally transport across the DR Congo is severely limited. It is a country crisscrossed by many streams and rivers, where the rainy season nearly always causes the rural earth roads to be barely passable.

The roads in the east serve as the primary trade route for the central-eastern and north-eastern part of that country. Of all the routes in that area, National Route 4 is the route most frequently used by relief agencies and rural farmers. It is also part of the transcontinental Lagos-Mombasa highway between West and East Africa. With no alternative routes, its upkeep is critical for delivering aid and food to and from this area.

Modern bridges are nearly non-existent in those parts and rudimentary more often than not. Some structures have fallen into dilapidated condition and no longer serve a useful purpose.In view of ever-increasing traffic loads, the need for replacement of such structures is a top priority.

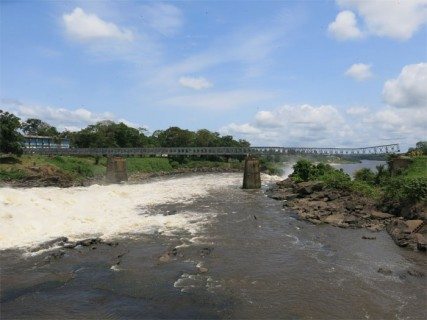

The old Tshopo Falls Bridge on the outskirts of Kisangani was one of those structures to be replaced. Kisangani is the third largest city in the country and the largest city in the tropical woodlands of the Congo.The city is located on two rivers: on the Congo River to its south and on the Tshopo river to its north. There, where the Tshopo river descends through a dam and, immediately below, a waterfall, a truss bridge was built in 1968.

In recent years, it had fallen into serious disrepair.As the bridge had served as the only access point to the city for the many farmers from the north-east, the authorities decided to have it rebuilt in as little time as possible, planning to keep traffic congestions at a nearby ferry service to an absolute minimum. It is no wonder then that the Ministry of Infrastructure, Public Works and Reconstruction (Office des Routes) acquired a modern panel bridge (Bailey-type), which is the only bridge type that can be installed within a few weeks.

On 25th October 2014, Joseph Kabila, President of the Democratic Republic of the Congo, held the official opening ceremony for the new Tshopo Bridge, a 163-metre panel bridge. It opened to road users a few days later and has been well received by local residents. The new steel structure was supplied by Waagner-Biro and provides increased capacity and improved safety for road vehicles and pedestrians alike. This project was the second big panel bridge contract that Waagner-Biro had obtained in DR Congo within a year.

Construction took a total of four months to complete, during which time the old bridge was first dismantled, the piers rehabilitated, and the new bridge launched across the wide valley of the wild Tshoporiver.

The new panel bridge is a robust one-storey construction and allows safe and reliable passage for heavy lorries up to 41 tons. The old bridge only allowed 25-ton vehicles to pass, using a multi-storey arrangement of panels. The new structure is a single-lane bridge with a 4.20-metre steel deck. Fitted along the main truss are two external walkways for safe crossing of the river by pedestrians. The single spans are 18.3 metres (60 feet), 39.6 metres (130 feet), 54.9 metres (180 feet) and 42.7 metres (140 feet).

Of the four spans, three cross the river, for which purpose they are connected by span junction.This equipment pins one span to the end of another and transfers shear while allowing the free rotation of the bridge spans in the vertical plane. This gives the Waagner-Biro panel bridge a multi-span capability and allows it to be constructed over existing piers, as was the case with the new Tshopo Bridge. The shortest of the four spans is not linked to the other three spans, since it is set six metres apart from them and rests on separate abutments.

Before the new bridge could be installed, the old one had to be dismantled. This was carried out by Office des Routesand took two months. Then the abutments and piers were revitalized and reinforced in order to support the higher loads from the new bridge.

In early August 2014, Waagner-Biro sent a specialist to the construction site to supervise the assembly and launching of the new steel structure across the river. Assembly of the four spans took approximately four weeks. What followed was a novelty even for Waagner-Biro. Never before had a total of four panel bridge spans (three spans for the main bridge, one span for the side bridge) been coupled together, put on rollers and pushed over four abutments and two piers.

The traditional approach would have been to launch the two bridges separately. In order to save time, it was decided to pushall spans as a whole. As soon as the side span was in place, it was de-coupled from the rest of the structure. The latter was then pushed onwards to the abutment on the other side of the river.The bridge structure with a launching nose at its tip totalled nearly 180 metres and 280 tons.

The assembly process proved to be a challenge. The city of Kisangani is situated in the middle of the vast tropical woodland of the Congo. Technical aids and machinery were mostly unavailable and if they were, they would break down frequently, so improvisation skills were called upon during the entire installation.

The high humidity and temperature levels in these parts also meant that the workers tired faster than usual and had to rest repeatedly. Nevertheless, after a total of four months, and thanks to the excellent expertise of the technical team at Office des Routes and Waagner-Biro, the new panel bridge was successfully pushed into its final position.

Until today the Tshopo river crossing has served as a crucial link on the only trade route connecting the city of Kisangani with the north-eastern part of the DR Congo. The new panel bridge will ensure continued accessibility between East and West Africa and improved reliability for many decades to come.

This example also proves how in remote and rural areas a modular steel bridge like the panel bridge can turn out to be the better choice. Panel bridges are easy to handle and simple to build. Made up of interchangeable elements that pin together, they adapt easily to different spans, deck widths and traffic loads. On top of that, they can be installed in a few days by unskilled workers only.

—TSHOPO II BRIDGE

Type of bridge: Span junction road bridge

Type of deck: Steel deck

Spans: 18.3m + 39.6m+54.9m+42.7m

Width: 4.20m (single lane)

Weight: 280 tons

Completion: 2014—