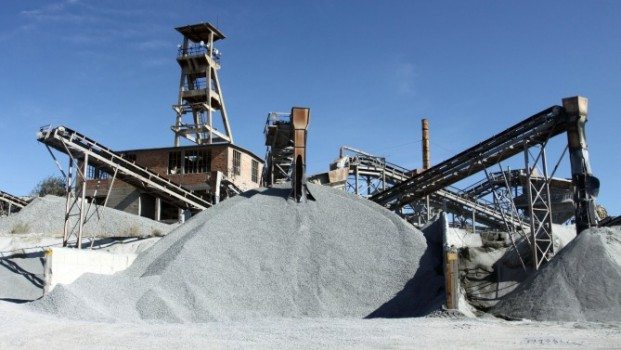

Cement demand in East Africa

Increasing cement demand in East Africa is increasing equipment supply to the region especially from Germany and China. The demand is being exacerbated by booming construction activities in the region, a recent Africa cement industry analysis by Ecobank has revealed.

East Africa’s installed cement capacity is currently estimated at 15.6 million tonnes, with 8.6 million tonnes of that figure produced in Kenya. Tanzania, Uganda and Rwanda have 4.9, 1.95 and 0.15 million tonnes of cement capacity respectively.

According to the report the region’s clinker capacity is estimated to be 5.98 million tonnes, including Kenya’s 3.18 million tonnes. Tanzania, Uganda and Rwanda have an estimated 1.87, 0.86 and 0.07 million tonnes of clinker capacity respectively.

The report observes that investors remain optimistic over African cement markets, attracted strong real GDP growth, forecast to average 4.5% in 2015. Ongoing construction projects in real estate has also helped instill hope to investors.

East Africa’s cement industry has also been a hotbed of a new investment of cement led by Nigeria-based quoted cement maker Dangote Cement, which has a $452 million, 3 million tonnes-capacity plant in Tanzania.

CIMERWA Rwanda’s sole cement maker has unveiled its new $170 million plant with capacity to produce six times the current 100,000 tonnes/year.

Cement machinery and equipment

It is this growth of the region’s cement industry that has attracted mechanical and engineering companies from Germany and China, who are now seeking to expand their ties with cement makers in East Africa.

“The increasing demand for cement in East Africa is fertile ground for business for German mechanical and plant engineering companies,” says Bernhard Pagenkemper, head of sales at Germany-based Haver & Boecker, which provides cement packing, storing, logistics and processing technology.

With East Africa’s construction on the upward trend, international manufacturers of cement machinery and equipment could are likely to increase their sales, as many cement makers in the region seek additional and technologically-savvy facilities that would ensure increased high quality production at less cost.

Leave a Reply