Fibertex SA – part of a global organisation, with its head office in Denmark has recently been awarded ISO 9001:2015 quality management system certification at the Hammarsdale manufacturing plant.

“The Hammarsdale facility – one of seven Fibertex factories worldwide – manufactures an extensive range of non woven geosynthetic products, in line with stringent international and local quality, safety and environmental specifications,” says Clive Hitchcock, CEO, Fibertex SA. “The KZN plant has successfully completed a rigorous audit and is now certified to ISO 9001:2015 requirements. Fibertex SA was awarded the coveted CE marking in 2016 – a mandatory certification for products sold within the European Economic Area (EEA), with certain products being certified to exceed 100 years durability.

“The local operation, which is well positioned to meet growing demand for geosynthetic products, not only in Africa, but also from countries in Europe, Australasia and Asia, is the largest plant in Africa that manufactures geo textiles from virgin Polypropylene (PP).

“Fibertex UV stabilised virgin PP geo textiles are the only non woven geo textiles produced in Africa with certification for durability of over 100 years, in accordance with the latest EN standards. This feat is completely dependent on the basis of the materials of construction and that they are based on virgin polymer. To our knowledge, no product based on a recycled material has ever been proven to meet this standard, nor will ever be able to do so, based on the inherent variability of recycled feed stock.

“PP has specific application in areas where the textile may be in contact with alkaline conditions, for example in slimes dams and waste sites. Fibertex PP geotextiles offer a high level of chemical stability under a wide range of environmental conditions and have advantages in installations where the cost of failure may be extreme, in both financial and environmental terms. This is in marked contrast to an alternative polymer, polyester (PET), which decomposes in alkaline conditions, through a chemical reaction called “hydrolysis”, causing the polymer to disintegrate and lose strength.

“The Fibertex team is committed to building business enterprises in KZN and we work closely with local municipalities, engineers and contractors to provide locally manufactured products, for local projects.

“As part of our pledge to creating sustainable employment in the region, the company offers skills training to ensure every step in the quality control of production and during installation, is in accordance with impeccable standards.”

Fibertex has completed many local projects in KwaZulu-Natal recently, including the installation of geosynthetic sand containers (GSC Bags) at coastal rehabilitation projects in Umdloti and Ballito. GSC-Bags were also successfully used as an alternative to concrete block walls in a prestigious landscaping project in Umhlanga Ridge.

Local projects enable Fibertex to create valuable job opportunities within KZN and specifically in the Hammarsdale region, which was once a thriving textile industrial hub.

The Fibertex geosynthetics range encompasses non woven and woven geotextiles, gabions and mattresses, drainage pipes and fittings and erosion control and cellular confinement solutions. The company also supplies soil reinforcing products, including geogrids and geocells, as well as geosynthetic clay liners as part of composite lining systems in modern landfills.

These woven and non woven geotextiles play an important role in diverse sectors, including mining, civil engineering, construction, waste and environmental fields. The company also offers solutions to automotive, filtration, furniture and flooring industries.

The company’s continued focus on quality and customer needs has led to the expansion and improvement of business operations. Coupled with this, global support guarantees the edge on product design, pristine manufacturing standards, cost efficiency, safety and reliability of every material.

The Fibertex group celebrates 50 years of business this year.

Suggested Caption

Fibertex SA Hammarsdale Plant awarded ISO 9001 : 2016 quality management certification

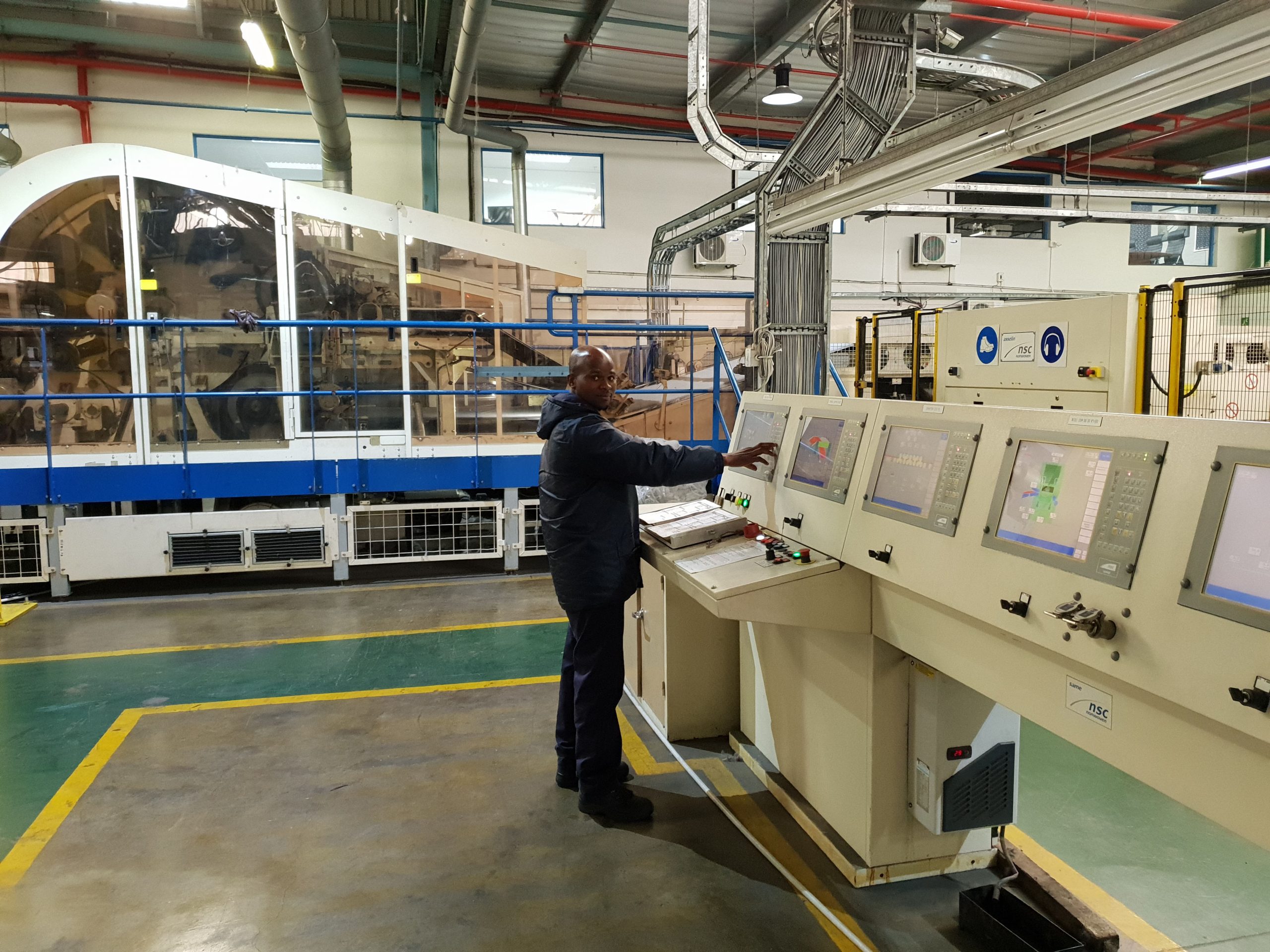

Njabula Mbhele, production supervisor, Fibertex SA is setting the card and crosslapper on needle line 1 at the company’s local manufacturing plant.

GSC Bags – KwaZulu-Natal coast rehabilitation – Ballito

Fibertex geotextile sand containers (GSC-Bags) are manufactured at the Fibertex plant in Hammarsdale from highly UV stabilised virgin Polypropylene (PP) fibres. GSC-Bags can withstand the effects of repeated wave attacks in harsh coastal environments and are the perfect soft solution to beach rehabilitation and coastal protection.

GSC-Bags – landscaping project in KZN

Fibertex geosynthetic sand containers (GSC-Bags) have been successfully used by WBB Builders, as an alternative to conventional earth retention systems, at recently completed landscaping projects in Umhlanga Ridge, KwaZulu-Natal.

For further information Clive Hitchcock, CEO, Fibertex South Africa (Pty) Ltd

16 Van Eck Avenue, Hammarsdale, 3700

Telephone (031) 736 7100

Email [email protected]

Web www.fibertex.com

Released by Lindy Morton, Festivitas 083 268 6666 e-mail : [email protected]

July 2018