The Grand Egyptian Museum will reportedly be open to the public in the coming days after multiple delays. The project was initiated in 2003, however, construction works did not begin until the year 2005. Many environmental and financial setbacks delayed the project.

At the break of the Arabic Spring in early 2011, work on the Grand Egyptian Museum project came to a complete halt. This was partly due to Egypt’s reduction in tourism and financial stability.

In 2014, the project resumed with the help of international loans to cover the lingering effects of the Egyptian revolution on the North African country’s economy.

Initially, the Grand Egyptian Museum was set to be open to the public in late 2020.

An overview of Grand Egyptian Museum (GEM)

The Grand Egyptian Museum (GEM), also known as the Giza Museum is positioned on 50 hectares (120 acres) of land around two kilometers from the Giza pyramids and is part of a new master plan for the plateau.

The museum is one of the largest museums in the entire universe presenting a heritage devoted to a single civilization and it is designed to include the latest technology, including virtual reality at a whopping cost of US $1bn.

It will also be an international center of communication between museums, to promote direct contact with other local and international museums. It shall, in addition, include a children’s museum, conference center, training center, and workshops similar to the old Pharaonic places. The GEM is expected to house around 100,000 artifacts from various periods of Egypt’s wealthy long history.

Approximately 20,000 artifacts will be exclusively displayed for the first time ever on this structure. The artifacts according to the GEM’s General Manager Tarek Tawfik, are composed of two 7,000 square meter galleries revealing King Tutankhamun’s lifestyle; how he lived, dressed, and ate in addition to the complete collection of his precious belongings.

This display has never been shown before since it’s unearthing in 1922.

Reported earlier

August 2015

Sigh of relief as construction of Grand Egyptian Museum nears completion

The construction of the Grand Egyptian museum is almost complete after surpassing the deadline date that was set in May. According to Egypt’s antiquities minister the project construction which was facing a financial crisis early in April got a boost after the government of Egypt chipped in and gave it support.

Early in April, the minister of Antiquities said that the project construction needed a further $US 300 million to complete the Grand Egyptian Museum. The announcement came as costs of the new museum rose from $US 800 million to $US 1.1 billion, said Antiquities Minister Mamdouh Al-Damaty. He also added that once the museum construction will be complete it will be managed internationally so that it can be independent to avoid bureaucracy.

The museum pyramids will be run independently so that the Gaza pyramid can be independent more than it was before the project kicked off. The Grand Egyptian Museum in Egypt is the largest in the world and is expected to be officially opened by the end of 2015. Private, international sponsorship was needed, he said, suggesting that the names of individual donors be written on the walls of the museum as an incentive.

The Egyptian government is trying to revive its battered tourism industry after four years of turmoil. Only the foundation and a few structures of the museum have been built so far. It was originally scheduled to have opened years ago but was repeatedly delayed over what the government said was a lack of funds. The latest official target aims for a 2018 opening.

October 2015

Shortage of funds delays the construction of the Grand Egyptian Museum

The construction of the Grand Egyptian Museum has been delayed over time since the conclusion of its design due to the challenge of fundraising $795 million for the project. Now, a state prosecutor in Egypt has ordered an investigation into the possible embezzlement of foreign funds loaned for the museum’s construction.

The Japan International Cooperation Agency (JICA) loaned $400 million to the Egyptian government for the project in 2006, with a favorable 1.5 percent interest rate and a grace period of 10 years, and the investigation follows media reports concerning the alleged embezzlement of some $20 million in funding earmarked for the project.

Construction on the Giza-sited, Henaghan Peng–designed institution began in March 2012, with an initial completion date of August 2015. The opening has since been pushed back to beyond 2018. This is the second major allegation of impropriety to involve the construction of Egypt’s museum.

In March, the director of the country’s museums authority was arrested on bribery charges connected with restoration work on the Museum of Islamic Art in Cairo, which was damaged in January 2014 by a suicide bomb attack against a police station nearby. Egypt’s administrative prosecution ordered an investigation into the alleged embezzlement of funds allocated to construct the Grand Egyptian Museum early this year.

The mega museum is situated near the Giza Pyramids about 2 km away on an approximately 500 000 square meters piece of land. Phases 1 and 2 which included the construction of the museum’s conservation and energy centers are already complete.

Oct 2016

Japan to provide US$ 460m for the construction of Egypt’s Grand Museum

Japanese ambassador to Egypt and Egypt’s Minister for International Cooperation signed a US$ 460m agreement for the construction of Egypt’s Grand Museum.

The Minister of International Cooperation Sahar Nasr and the Japanese ambassador to Egypt Takehiro Kagawa signed the loan that will finance the second phase of the Museum. Also, the Minister for Antiquities Khaled El-Anany also signed the agreement for the project with Teruyuki Ito, chief representative of the Japan International Cooperation Agency (JICA)

Dr. Sahar Nasr commented during the signing of the loan saying that Egypt and Japan have had good relations and the project will be one of the biggest museums in the world, housing more than 100,000 pieces including the Tutankhamun artifacts. It will attract tourists from all over the globe.

“The new Egypt’s Grand Museum will be a big achievement once complete since it will attract visitors and tourists from all over the world,” said Dr. Nasr.

The museum is currently under construction where approximately 50% is complete with the first phase scheduled to be opened in 2017. All construction phases would be complete in 2022.

Japan not only has the function of financing the construction but also facilitates the use of cutting-edge Japanese technology in different fields, for instance, the restoration of monuments. Japan is also working with Egypt on different projects in other fields, like renewable energy.

December 2018

Contract for operation and maintenance of Grand Egyptian Museum (GEM)

Grand Egyptian Museum (GEM) will be operated and provided services and facilities by a consortium that is made up of Hassan Allam Holding subsidiary (Hassan Allam Construction) and the MAB group of companies, which are headquartered in the United Arab Emirates (UAE).

The consortium which also includes other global leaders from France, the United Kingdom (UK), and other countries in tourism promotion, cultural programming, business management, marketing, and quality control will work together with the North African country’s Ministry of Tourism and Antiquities.

The GEM, which is poised to be among the world’s leading cultural and tourist landmarks, highlights the Egyptian Government’s framework and commitment to support its tourism industry. Also Read: ECO West Project, New City Developments latest, launched in Egypt

Proud to be selected as the partner of choice, helping deliver Egypt’s vision.

According to Hassan Allam, the Chief Executive Officer (CEO) of Hassan Allam Holding the company is proud to be selected as the partner of choice, helping deliver the North African country’s vision.

“It is an unparalleled honor to have been selected to operate and provide services and facilities at what will be one of the most important museums in the entire world. Egypt’s rich history and attractions already offer visitors a diverse experience on which the GEM builds, elevating the country to a commanding place on the global tourism map.

We recognize the unique privilege that has been bestowed upon us in playing such a central role in the Grand Egyptian Museum and we are excited to start work towards the Government’s strategy of developing sustainable museums and attractions,” said Mr. Allam.

A testament to Hassan Allam Holding’s experience in implementing large and complex projects in Egypt

The Hassan Allam Holding CEO said that being selected to operate and provide services and facilities at the GEM is a testament to the company’s experience in implementing large and complex projects in Egypt and the region for 85 years. He added that it cements its position as a key partner in mega projects of strategic and national importance.

February 2019

Grand Egyptian Museum nears completion

The Grand Egyptian Museum (GEM) also known as the Giza Museum nears completion. This is according to the Minister of Antiquities Khaled al-Anani who said the project is standing at 88% complete. Khaled al-Anani said that the GEM development is one of the ministry’s largest projects in the country.

The opening of the museum had been set for two dates last year 2018 but to the disappointment of the public, it was never commissioned. Anani however affirmed that with the current progress, there is no doubt that the museum shall be ready for exhibitions by the year 2020.

July 2019

Construction of the Grand Egyptian Museum at 90% complete

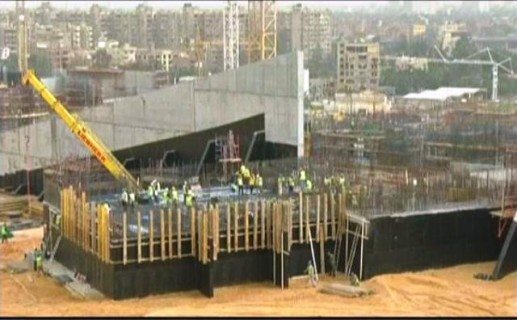

Construction works on phase 3 of the Grand Egyptian Museum project are 90% complete. Egypt’s Prime Minister Dr. Mostafa Madbouli announced the reports when he site near the Giza Pyramids to review the progress.

Laurens Schokking, the Project Director explained to the Minister that concrete and steel works had hit 98% and 99% progress respectively. He added that mechanical, engineering, and plumbing work at the museum, including the main building, the central square, and the Ramses hall as well as the 3,200-year-old statue of King Ramses II that weighs 75 tons at present stands at 84%.

Laurens also noted that finishes were 96% complete. He foresees completion of phase 3 of the project by the end of this year. The Grand Egyptian Museum’s phase 3 is being built by Egyptian contracting company, Orascom Construction, together with Besix Group from Belgium, which is one of the leading construction companies ranked 69 in the list of top international contractors.

December 2019

Grand Egyptian Museum updates pyramid aesthetic with post-tensioned folded plate roof

For centuries, people have been fascinated by the culture and achievements of the ancient Egyptian civilization. Along with a legacy of art, science, spirituality, and engineering, the ancient Egyptians also left in their wake a global trade in artifacts, many of which have been taken from their native Egypt over the centuries for both private collections and public display.

Now, for the first time, Egypt is set to counter that legacy of lost treasures by creating the most comprehensive collection of Egyptian antiquities in a single museum anywhere on the planet. Due to open in 2020, the Grand Egyptian Museum will be the largest archaeological museum anywhere in the world, with more than 100,000 artifacts in its collection.

It will also display the full Tutankhamun collection in a single location, with many of the 3,500 pieces on view to the public for the first time. But it’s not only the exhibits within the museum that have caused excitement around the world. Located in Giza, the museum building itself has already become a landmark ’ must-visit attraction.

The project was the subject of an architectural competition, which received 1557 entries from 82 countries, with a winning design by Irish architectural practice, Heneghan Peng, selected for the project. The building’s chamfered triangle shape references the iconic pyramids while creating a striking, contemporary structure that accommodates a huge, open-plan main hall.

The museum’s unusual silhouette has been achieved thanks to engineering from the project’s structural engineer, Arup, which relies heavily on the structural capabilities of post-tensioned concrete. The building’s design includes a roof with a total construction area of 10,000m2 of post-tensioned folded plates, along with post-tensioned edge beams and a cantilevered wall.

The post-tensioning element of the project was delivered by CCL, the specialist in engineered solutions for structures, and the company’s partner in Egypt, CSS. The two companies worked together to provide the materials, equipment, and expertise required on-site.

Folded Plate Roof

Aesthetically, the folded plate roof continues the chamfered triangle design theme to the roof of the building. Technically, achieving this look involved considerable challenges. The roof structure is composed of post-tensioned folded plates with different inclinations and spans varying between 18m and 30m.

Arup requested that CSS supply CCL post-tensioning tendons containing 19 strands to provide the significant amount of PT forces required for lateral stability and seismic loads. Other design factors also influenced the design of the post-tensioning, including the removal of some of the lateral beams originally designed into the roof structure, which increased the amount of PT forces required.

The relatively slim concrete thickness of the folded plates – just 275mm – and the varying inclinations also created buildability challenges, because it made it difficult to accommodate the live-end and dead-end PT anchors at the intersection of the angled plates.

This was addressed at the shop drawing stage by the CSS team, who suggested an increase in the thickness of the concrete cover at the intersection of the folded plates from the upper part of the roof. This solution provided the increased thickness needed for the PT anchors in a location where it will not be visible and was approved by both the engineering team and the client.

Beams

The structural design for the Grand Egyptian Museum building also includes six post-tensioned beams, with spans ranging from 14m to 38 m, located parallel to the folded plate roof. These beams support the structural loading of the roof and manage the deflections. Each of these beams was constructed with three tendons and installed using the CCL XM60 anchorage system.

The building also features a 22 m-long cantilever wall, which is 8.65 meters deep. This wall performs the role of a deep beam and was designed with six tendons, each incorporating 19 strands, using the CCL XM60 post-tensioning system. Once again, the CSS team had to address buildability challenges in the design of the wall at the shop drawing stage for the PT installation, due to the narrow 45cm width of this cantilever wall/deep beam.

Ahmed Zaky, CEO of CSS explains: “The live-end and dead-end PT anchors for the CCL XM60 system require a minimum concrete thickness of 50cm but the wall had been designed to provide a slim, elegant aesthetic, which could have been compromised by increasing the thickness of the concrete for structural reasons.

“To resolve the problem without altering the visual appeal of the wall/beam, we proposed increasing the width gradually over the course of around one meter of its length. This solution ensured the thickness of the concrete was sufficient to accommodate the PT anchors at the relevant points in the structure, without detracting from the slenderness of the architectural design.”

Once again, the structural engineer and the client were happy with CSS’s proposal and this was incorporated into the final scheme.

Proven Expertise

Unlike many of CCL’s projects around the world, the company was not involved in the Grand Egyptian Museum at the design stage, but the involvement and expertise of CCL and CSS were critical in developing the buildability of the design and delivering the project on-site.

Explains Tedy Chakhtoura, COO of MENA/Africa at CCL: “During the tendering phase, the client’s primary concern was identifying a post-tensioning specialist that could complete this element of the project to the highest quality standards. Speed of project delivery and the availability of experienced personnel was also critical to ensure there was no possibility that the post-tensioning works could cause delays to the wider program.

“CCL’s PT system and expertise have been proven around the world, including a number of showpiece projects in North Africa, and our PT anchorage system holds ETA and UK CARES certification. Consequently, we were able to offer the client the level of quality assurance they required along with local PT experts through our partner in Egypt, CSS.

CSS provided the shop drawings for all the PT works on the Grand Egyptian Museum project and technical support throughout the design development and construction process. CCL supplied all the strands and anchorages for the program, according to the design team’s specification, and also worked with CSS on the installation of the PT on site for the folded plates, edge beams, and cantilever wall, stressing the tendons using the CCL Multistressing Jack (4000 MG) and CCL Hydraulic Pump (SR5000).

Finally, the CSS/CCL team was also responsible for grouting the tendons to complete the PT works. The PT elements of the project have now been completed and the Grand Egyptian Museum is due to open its doors to the public for the first time in 2020.

December 2021

Grand Egyptian Museum to Open its Doors to the Public in 2nd Half of 2022

The Grand Egyptian Museum, an archaeological museum that is also known as the Giza Museum, under construction on a 117 acres piece of land in Giza, an Egyptian city on the west bank of the Nile, near Cairo, is set to open its doors to the public in the second half of next year, after an unfortunate delay caused by the wake of the Covid-19 pandemic.

This was reportedly revealed by Mostafa Waziri, the Secretary-General of the Supreme Council of Antiquities while speaking at the Egypt Pavilion during the Expo 2020, a World Expo hosted by Dubai in the United Arab Emirates from the 1st of 1 October 2021 to the 31st of March 2022.

“The construction work of the Grand Egyptian Museum is now fully complete, and work on the display areas is ongoing. We can also confirm that we have completed work on the exhibits that will be displayed at the Museum,” said Mr. Waziri.

Ancient Egyptian treasures for the Grand Egyptian Museum

During a recent symposium on excavations in the North African Country, the Secretary-General of the Supreme Council of Antiquities reviewed some recent discoveries and revealed more projects to excavate ancient Egyptian treasures.

He said that what we see above the surface of the earth in Egypt is barely 40% of the antiquities contained below the ground adding that there are more than 50 Egyptian missions working at various sites, and discoveries in Luxor, Minya, Sohag, Saqqara, Cairo, and the Lower Egypt region.

Waziri also revealed how Egyptian teams managed to reinstate important statues in the Luxor area, including a statue of King Ramses II, who ruled the North African country for 66 years between 1279 and 1213 BC.