Harnessing the limitless energy of the sun has been a goal for the power generation industry for many years, but the unpredictability of the weather has always been the main issue the industry has faced in the widespread adoption of the use of solar power. Cloud cover significantly reduces the amount of solar radiation that hits the photovoltaic panels, reducing the amount of energy produced, and thus reducing their efficiency. Another source of electricity is therefore needed to supplement the solar power when it is not available – in areas without the grid electricity infrastructure it is usually a diesel generator (this is commonly called a PV/Diesel hybrid system). Having a diesel generator run on standby, just in case the cloud cover changes, and the solar output drops are very inefficient, uses a lot of diesel fuel, wears the generator out, and has a negative impact on the operational costs reduction and the environment.

Under normal circumstances, to ensure the reliability of the power supply, hybrid applications require a high dynamic spinning reserve (i.e. keeping the gen-sets running even when the PV system generates energy) so that they can immediately replace a potential drop in electricity production caused by cloud cover. The diesel gen-sets are thus operated at a low load level, which reduces production efficiency, negatively impacts the possible fuel savings, and extends the return on investment for high PV penetration systems. Apart from this, running generators at a low load also has a negative effect on the generator itself as carbon black and other impurities settle because of the suboptimal combustion process.

Optimization by tracking cloud movement

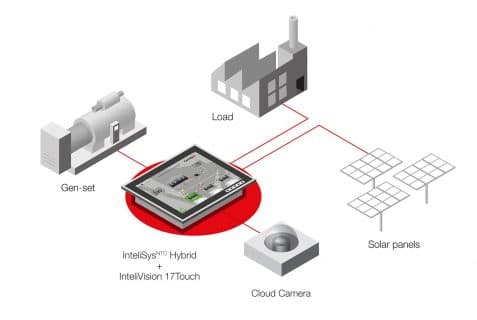

How can the operation of these hybrid systems be optimized? ComAp is currently preparing a pilot project to test a new solution with its Cloud Forecasting System; a system for tracking cloud movement and forecasting electricity generation from a photovoltaic power plant and is particularly suited to hybrid applications with a high proportion of PV power.

“The system is made up of a fish-eye camera and an industrial computer. The camera continuously monitors the sky, monitoring both the size and movement of the clouds and the intensity of the sun’s radiation. The computer then processes the data obtained to predict cloud cover and the expected irradiation and thus the output of the PV plant in that area. The data from the local computer is then processed in the ComAp control system (InteliSys NTC Hybrid), where it serves to calculate the above-mentioned dynamic spinning reserve. It is this that the entire system’s efficiency depends on. The lower the spinning reserve on the gen-sets, the greater the fuel savings, the reduction in emissions, and the reduction in operating costs,” explains Petra Píclová, head of the Renewable Energy Division at ComAp. “A forecast that is faster and more accurate than satellite data is provided for the next five minutes, which is more than enough time to start diesel gen-sets in the event of an expected drop in the output from a photovoltaic power plant,” she adds.

The continuous updating of the predicted values improves the forecast’s accuracy and reliability, which allows the control system to optimize the operation of the hybrid microgrid and increase its efficiency. The history from the measured data on cloud movement allows the prediction algorithm to be continuously improved and the subsequent refinement of the predictions provided. The system is suitable for commercial and industrial use, one camera is sufficient for a 1-2 MW photovoltaic power plant.

With growing prediction accuracy, it is possible to imagine a camera system replacing expensive battery storage in the role of an uninterruptible power source (UPS). The price of a camera system is negligible compared to the price of a UPS for large installations generating several tens of MW.