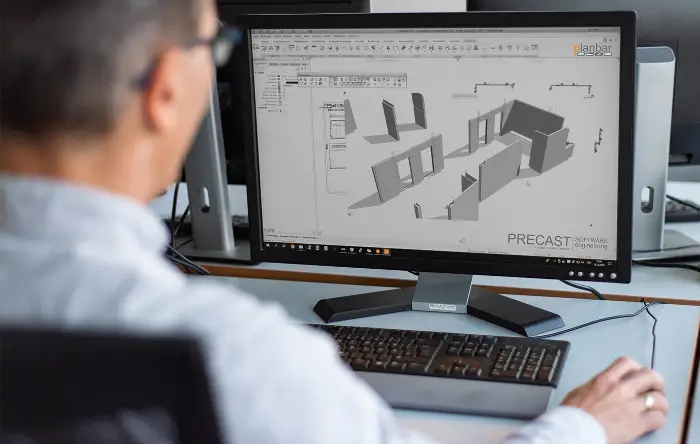

30 years of R&D – with unwavering innovation: PLANBAR and TIM have become indispensable tools for thousands of precast CAD designers, engineers and operations schedulers worldwide. The latest software releases further strengthen offerings in a future-proof branch of industry – and once again prove eye-opening. With greatly expanded automation features in design and planning, the software also helps to prevent accidents in production and assembly.

PLANBAR is the world’s top CAD solution for designing and detailing precast concrete parts – easy to learn, with time-saving assistants and smart features that make 3D as easy as 2D. Together with TIM, PLANBAR is iconic for its ability to provide precise and efficient precast designing, process planning and production planning. The most popular features include reinforcement at a click, generating automatic element plans, and 3D stacking.

Why do we continue to tirelessly develop these two software solutions to provide even greater efficiency and precision, despite functionality that has been a proven success for years?

“We want to make the most efficient even more efficient, the most precise even more precise, and the most secure even more secure. After all, we see our tools as an essential success factor to help our customers improve their competitive edge and productivity,” states Werner Maresch, Managing Director at PRECAST Software Engineering, explaining the roots of the new, powerful features. “We are particularly proud of the innovative quality assurance tools that can help prevent time-consuming errors and even accidents – if, for example, the risk of tipping occurs when stacking, our software triggers an alarm.”

Another focus in the development of the new versions, in addition to efficiency and security, was on quality assurance of data for production and business systems. “Quality-assured data and its smooth flow ensure maximum possible efficiency in precast projects,” explains Peter Kafka, mathematician and BIM pioneer at PRECAST Software Engineering: “This means you need both – features that improve efficiency and 100% commitment to seamless data quality. Ultimately, error-free data are also a precondition for maximum cost and time efficiency – replacing defective parts in a new production run eats the most into margins, and our software helps to ensure that designs are correct.”

PLANBAR and TIM 2021 – redefining long-term reliability

For the newest versions of its smart software products, PRECAST Software Engineering – the leading international full-service provider of software solutions and services for the precast concrete industry – once again spared no effort or expense: A total of 150,760 hours – and that is only the recorded hours, not counting the ideas bandied about at all hours by our enthusiastic developers – went into the next development step. What does it consist of? The new releases provide more than 4,500 production upgrades and new features to provide even better performance in PLANBAR and TIM and efficiency never before seen. One example of this is the new TOPIC BOARD, available in PLANBAR and TIM, which greatly simplifies cross-departmental collaboration, saves time and provides even better flow in precast projects.

What specific added features can we expect from the upgrade on 07 Dec 2020?

Customers who already use PLANBAR and TIM will be happy about the noticeably improved performance, more openBIM, and further advanced automation options. 4,500 new features, even more automation – although the whole has always been more than the sum of its parts and a smart integrated solution cannot be summed up in a few words, the info box provides an overview of the new highlights of PLANBAR and TIM from PRECAST Software Engineering, part of the Nemetschek Group.

PLANBAR 2021 HIGHLIGHTS: Enhanced performance

- “Views and Sections” up to 20x faster.

- Very large projects load at rates up to 4x faster.

- Title block and legends in element plans processed 10x faster.

- The automatic dimensioning in element plans has been optimised.

- Switch to layout editor up to 10x faster.

Perfect visualisation of curves and irregular shapes

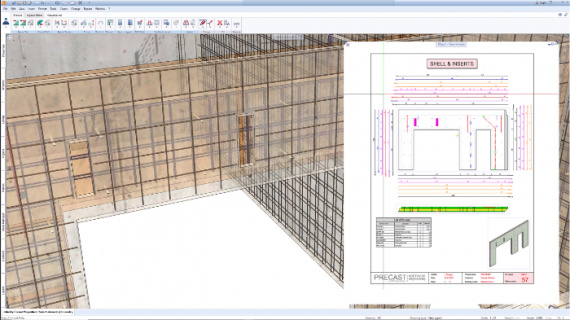

- We now also process freely modelable bodies with round surfaces as precast elements. The world’s top modeling kernel Parasolid from Siemens ensures displaying the elements with the highest level of performance and precision.

- This innovation opens innovative design and production possibilities such as 3D printing and carbon-concrete construction.

Highly efficient handling of larger projects

- Do you have large projects with numerous identical elements? You no longer have to manually change identical parts in iWall – the BIM-BOOSTER takes over this for you and gives you time for more challenging activities.

- Large projects no longer have to be split up in a time-consuming process.

Advanced MEP-ASSISTANT for even more efficient import of fixtures

- Import MEP elements easily from other sources. MEP-ASSISTANT transforms these into fixtures or openings. PLANBAR takes care of the adjustment of reinforcement and dimensioning fully automatically. With just a few clicks, PLANBAR generates plans, lists and production data for you.

- PLANBAR now also processes additional MEP elements – and provides you with more flexibility and efficiency.

Model complex iWall elements

- With the “Dissolve Elementation” feature, you can edit individual wall elements easily as 3D elements. PLANBAR takes care of the reinforcement and dimensioning fully automatically for you – and provides reduced risk of error, more convenience and more productivity.

- As an option, BIM BOOSTER provides an additional productivity boost when designing complex wall elements.

Improved PythonParts functionality

- PythonParts allows users to create 3D models using simple parametric input – enter a few values and the complete 3D model of stairs or columns is ready for you.

- PLANBAR 2021 brings a further development of the automatic reinforcement for stairs and columns, as well as more extensive options for fixtures.

TIM 2021 HIGHLIGHTS:

Improved accuracy and quality thanks to highly expanded testing system

- In our QUALITY MANAGER module, you can now define a large number of new rules that TIM ensures users comply with.

- Have the correct fixtures been installed or are these positioned properly? Is there an adequate number of lifting anchors for the weight of the precast part? Have the lifting anchors been positioned properly in relation to the centre of gravity of the precast part? Does the lowest precast part on the stack of a ceiling have no cut-outs so the stack does not break during loading?

- TIM not only knows the answers to these questions but also to many other questions, and automatically generates tasks for processing. This helps to prevent errors and accidents, and protects human life!

- TIM also supports testing in third-party systems, for example, by using automated IFC export and BCF import (= international BIM exchange format for tasks and comments).

Improved teamwork with the new TOPIC BOARD

- In TIM you’ll find our new TOPIC BOARD – including integration with PLANBAR. Tasks and information can be generated manually, using BCF import, by other software systems or via rule infractions from the QUALITY MANAGER.

- Depending on the application, these tasks are also available for processing in PLANBAR. As a central platform, TIM manages the authorizations for PLANBAR and TIM, as well as the editing options – a helpful new feature designed to help customers simplify and accelerate collaboration across departments.

Customized export of IFC files for greater interoperability

- In addition to exports in the established IFC4precast format, TIM now also supports a customised IFC format. In the settings, you can define relevant IFC objects and IFC attributes of the precast elements to be exported to an IFC file. This ensures you can easily meet application- and project-specific requirements. This feature guarantees successful interaction with downstream BIM applications – for lived openBIM.