In the modern construction industry, additives are just as important as the cement and sand themselves. We often focus on the big materials, but it is the “invisible” binders that determine whether a facade stays intact for 20 years or cracks after a single winter. Among these, Polyvinyl Alcohol (PVA) is a staple for improving flexibility and adhesion.

However, after years of supplying additives to construction sites, I have noticed a recurring issue: many engineers treat all PVA powders as the same product. They order “PVA” without specifying the grade, often leading to mixing issues or poor water resistance.

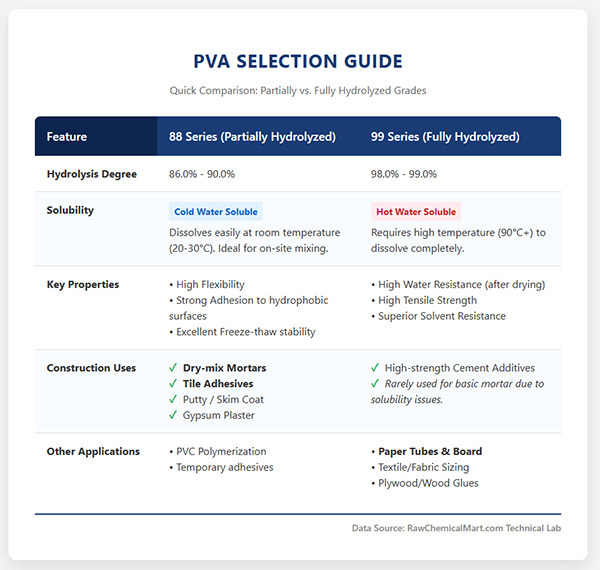

The truth is, the difference between a “Partially Hydrolyzed” grade and a “Fully Hydrolyzed” grade can be the difference between a successful project and a structural failure. This article breaks down exactly how to choose between the two main contenders: the 88 Series and the 99 Series.

To select the right binder, you don’t need a PhD in chemistry, but you do need to understand one concept: Degree of Hydrolysis. This simply measures how much of the acetate group has been removed during manufacturing. This percentage dictates how the powder reacts with water—a critical factor on a busy construction site.

The “88 Series” (such as PVA 17-88 or 24-88) refers to Partially Hydrolyzed PVA (usually around 86% – 89%).

Solubility: The biggest advantage here is cold-water solubility. You can dump this directly into a mixer with ambient temperature water, and it will dissolve smoothly. This is a huge time-saver on sites where heating water is impossible.

Performance: It offers excellent surface activity and flexibility.

Best For: We typically recommend this for tile adhesives, dry-mix mortars, and gypsum plasters where ease of use and flexibility are the main goals.

On the other end of the spectrum, we have the “99 Series” (like PVA 17-99 or 26-99). These are Fully Hydrolyzed (98% – 99%).

Solubility: This is where mistakes happen. The 99 Series does not dissolve in cold water. It requires temperatures above 90°C (194°F) to fully break down. If you try to mix this in a cold bucket, you will end up with clumps and weak spots in your mortar.

Performance: Once dissolved properly, however, it provides superior water resistance and tensile strength compared to the 88 Series. It creates a much more rigid and durable bond.

Best For: This is ideal for specialized applications requiring high water resistance, or high-strength solid adhesives where the manufacturing process involves heat.

The most frequent error we see is purchasing the 99 Series for a standard cold-mix mortar application because it is often perceived as “purer” or “stronger.” While it is stronger, if it doesn’t dissolve, it’s useless.

If your site does not have the capacity to heat water to near-boiling temperatures, stick to the 88 Series. It is more forgiving and provides the flexibility needed to withstand thermal expansion in exterior walls.

Next time you are sourcing additives, don’t just ask for “PVA.” Ask for the grade that fits your mixing equipment and your structural requirements.

For engineers who need a quick reference on viscosity and specific grade numbers (like 17-88 vs 24-88), my team has compiled a detailed Selection Guide Table. It compares the technical parameters of both series side-by-side to help you make the right call.

Selecting the right additive is a small step in procurement, but a giant leap for building safety.

Attached images:

Image 1: The PVA Comparison Table

-

Image Name: pva-selection-guide-table-88-vs-99-series.png

-

Alt Text: A technical comparison table titled ‘PVA Selection Guide’ from RawChemicalMart, detailing the differences between Partially Hydrolyzed (88 Series, cold water soluble) and Fully Hydrolyzed (99 Series, hot water soluble) Polyvinyl Alcohol grades, including their key properties and construction applications like tile adhesives and dry-mix mortars.

Image 2: The Construction Worker Photo

-

Image Name: worker-applying-pva-enhanced-mortar-brick-wall.jpg

-

Alt Text: Close-up photograph of a construction worker’s gloved hands using a trowel to apply a smooth, high-quality white mortar base, likely fortified with Polyvinyl Alcohol (PVA) additive for improved adhesion, onto a red brick wall on a sunny construction site.

Leave a Reply