A contract worth over US$ 590M has been granted for ‘green’ tunnel technology in the Fehmarnbelt Tunnel, which will connect Denmark and Germany. Femern has chosen SICE-Cobra, a Spanish-led consortium supported by corporations from the United States, Sweden, New Zealand, and Australia. The Fehmarnbelt Tunnel’s operation must be CO2-neutral, which necessitates energy-management systems. The electrical systems are among the most significant components of the 18-kilometer-long tunnel.

The project, which includes ventilation, lighting, and safety systems, was advertised as a design and build contract. “This contract is critical to our goal of making the Fehmarnbelt Tunnel the future green transport route,” said Femern technical director Jens Ole Kaslund. “All bidders presented high-quality offers that satisfied our expertise and qualification standards, however, the chosen consortium submitted the best bid in terms of price and quality.”

Read also: Top Mega Projects in the United Kingdom, Europe

Scope of the ‘green’ tunnel technology in the Fehmarnbelt Tunnel

The procurement procedure began in the spring of 2021 with a prequalification stage, during which three consortia submitted their initial tenders for negotiation in November. Femern stated that it opted to continue directly to the contract award process due to a very favorable negotiating offer from SICE-Cobra. “We are constructing a tunnel that will not only run entirely on renewable energy but will also utilize the electricity supplied as effectively as possible.” “The design and construction contractor must supply the right technical solutions for the opening in 2029 and adapt the installations to future green technologies,” Kaslund explained.

The consortium, like the other main contracts on the Fehmarnbelt project, is intended to involve a large number of subcontractors. Apprentices are also required to be employed by the contractors.

SICE-Cobra consists of:

Spain’s Sociedad Ibérica de Construcciones Eléctricas (SICE), Spain’s SICE Tecnologa y Sistemas, Spain’s Cobra Instalaciones y Servicios and Spain’s Moncobra.

The following organizations provide assistance:

Spain’s Cobra Instalaciones y Servicios Internacional, SICE from the United States, SICE Nordics from Sweden, SICE NZ from New Zealand, and SICE from Australia.

Fehmarn Belt Fixed Link Project overview

The Fehmarn Belt Fixed Link is the world’s longest immersed tunnel. It is currently being built to connect the Danish island of Lolland with the German island of Fehmarn, a distance of 18-kilometers across the Fehmarn Belt in the Baltic Sea.

Also Read: High Speed 2(HS2) Railway Project timeline and all you need to know

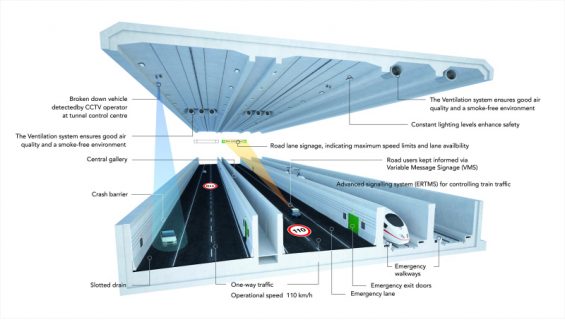

The project is one of Europe’s largest infrastructure projects with a construction budget of over US$ 8.2bn, and upon completion, it will be the world’s longest immersed tunnel. Furthermore, comprising two double-lane motorways (separated by a service passageway) and two electrified rail tracks, the Fehmarn Belt Fixed Link will be the longest combined road and rail tunnel anywhere in the world.

Originally set to be a typical bridge, the tunnel will shorten the travel time between Lolland and Fehmarn from 45 minutes by ferry to 10 minutes by car and seven minutes by an electrified high-speed rail that will be capable of reaching 200 km/h. It will also replace a heavily traveled ferry service from Rødby and Puttgarden, which is operated by Scandlines, a route known in German as the Vogelfluglinie and in Danish as Fugleflugtslinjen.

Construction of the Fehmarn Belt Fixed Link

The Fehmarn Belt Fixed Link project will involve the use of approximately 3.2 million tonnes of concrete and 360,000 tonnes of reinforced steel for the construction of the tunnel elements. The construction of the trench will involve the excavation of approximately 19 million cubic meters of stone and sand from the seabed.

About 73,000 tonnes of tunnel elements will be placed once the trench is ready. These elements including 79 standard elements, each measuring 217m-long, and ten special elements with an additional lower floor, will be towed using tugboats and then lowered into the seabed and assembled.

Each special element will be placed at a 2-kilometer space and comprise equipment for operation and maintenance.

The project team

The joint-venture (JV) of Ramboll, Arup, and TEC provided consultancy services in the technical area for the project, while Schønherr and WTM Engineers are engaged as sub-consultants.

ÅF-Hansen & Henneberg provided in-house consultancy services in the technical area of the project, while Atkins Danmark, OBERMEYER Planen + Beraten, ÅF Infrastructure were engaged as sub-consultants.

Femern Link Contractors (FLC) consortium which comprises VINCI Construction Grands Projects, Per Aarsleff Holding, Wayss & Freytag Ingenieurbau, Max Bögl Stiftung & Co, CFE, Solétanche-Bachy International, BAM Infra, and BAM International, is in charge of the construction of immersed tunnel and tunnel factories (Tunnel North and Tunnel South and the portals and ramps). Dredging International is the sub-contractor for the consortium, while COWI is the consultant.

With SWECO Danmark as the consultant, Fehmarn Belt Contractors (FBC) consortium comprising Boskalis International, HOCHTIEF Solutions, Züblin, and Van Oord Dredging and Marine Contractors is in charge of the dredging and reclamation work.

The European Union (EU) is co-financing the project as part of its Trans-European Transport Network program (TEN-T) and under its Connecting Europe Facility (CEF) program.

Project Timeline

2008

In September, Denmark and Germany signed the state treaty on a fixed link across the Fehmarn Belt

2009

The Denmark and Germany treaty was ratified by the Danish Parliament in April.

2011

In February, immersed tunnel method was chosen as the preferred technical solution for the fixed-link project.

2015

Germany and Denmark submitted a joint application to the EU Commission for EU grants for the construction phase of the proposed Fehmarnbelt tunnel in February.

The project construction was approved by the Danish Parliament in April.

In June, close to US$ 682.3M of EU funding was awarded to Denmark by the EU Commission under its CEF scheme.

2017

In March, the Fehmarn Belt Fixed Link operating company announced the sign-up of subcontractors for the project.

Oct 2020

Construction of the world’s longest tunnel, the Fehmarnbelt Tunnel, begins

After 10 years of planning, the construction of the world’s longest immersed tunnel has officially begun. The Fehmarnbelt Tunnel that will connect Denmark and Germany, is scheduled to be officially opened by 2029. It’s one of Europe’s largest ongoing infrastructure projects, with a budget of more than US$8 billion. The tunnel will have an 18 kilometers extension and will be built across the Fehmarn Belt, a strait between the German island of Fehmarn and the Danish island of Lolland. It will be an alternative to the current ferry service, which takes 45 minutes. Traveling through the tunnel will take seven minutes by train and ten minutes by car.

Also Read:75 tunnels for China-Laos railway project completed.

It will be the longest combined road and rail tunnel in the world, with two double-lane motorways, separated by a service passageway, and two electrified rail tracks. Besides the benefits to passenger trains and cars, it will have a positive impact on the flow of freight trucks and trains. The Fehmarnbelt Tunnel project started back in 2008 when Germany and Denmark signed a treaty to build the tunnel. But it took more than a decade for the necessary legislation to be passed by both countries and for geotechnical and environmental impact studies to be carried out. Still, many organizations have currently open appeals against the project.

In the meantime, amid precautions to keep workers safe from COVID-19, construction work started in the summer on the Danish side. Work will carry on for a few years in Denmark before moving into German territory. Workers are now building a new harbor in Lolland and in 2021 they will start construction of a factory, both meant to support work on the tunnel. Located behind the port, the factory will have six production lines to assemble the 89 massive concrete sections that will make up the tunnel. Each section will be 217 meters long, 42 meters wide, and 9 meters tall, weighing 73,000 metric tons each. They will be placed just beneath the seabed.

May 2020

Construction of the world’s longest immersed tunnel to begin

Construction of the world’s longest immersed tunnel for both road and rail traffic, between Rødbyhavn on Lolland, Denmark, and the German island of Fehmarn is set to begin. This is after Femern Link Contractors joint venture received notice to proceed from the Danish Government

The tunnel known as ‘Fehmarnbelt Fixed Link’ will consist of a motorway and rail connection including an 18 km long tunnel that will allow traveling faster and safer between Scandinavia and continental Europe. It will take less than 3 hours to travel by train between Hamburg & Copenhagen (currently, 4½ hours).

Also Read: NHIDCL awards US $315m Z-Morh Tunnel project to APCO Amarnathji Tunnelway

Construction of Fehmarnbelt Fixed Link

In contrast to a bored tunnel, an immersed tunnel is made up of hollow concrete elements, cast on land, and assembled section by section to form the tunnel.

A trench for the tunnel must first be dug in the seabed in order to build the Fehmarnbelt link. This trench will be up to 60 meters wide, 16 meters deep, and 18 kilometers long. In total, some 19 million cubic meters of stone and sand will be excavated from the seabed. This will be used to establish approximately three square kilometers of new natural areas on Lolland and, to a lesser extent, on Fehmarn.

When the trench in the seabed is ready, the work of putting the tunnel elements in place can go ahead. Each tunnel element weighs 73,000 tonnes, however, it can float in the water because it is hollow and sealed with bulkheads, Large tugboats will tow the elements out into the Fehmarnbelt, where they will be lowered down onto the seabed with a high degree of precision and then assembled.

When the tunnel tube is in place, the technical installations can be completed. These include tracks for the electric trains, communications systems, lighting, ventilation, transformers, and pumps. As an evolutionary change to the Øresund tunnel, the Fehmarnbelt tunnel will have 10 special elements with an additional lower floor.

A special element will be located approximately every two kilometers of tunnel and will have equipment for operation and maintenance. This means that the Fehmarnbelt tunnel will be cheaper and easier to maintain, and will require significantly less concrete since the standard elements can be made smaller.

2021

In January, work started on the Danish side at Rødby, with the construction of a large factory that will manufacture the 200-meter-long precast concrete box girders that will be sunk to make the tunnel.

In September, Trelleborg’s marine and infrastructure operation announced that it was awarded a contract to supply its tunnel seals to Femern Link Contractors (FLC) for the construction of the 18-kilometer long Fehmarnbelt tunnel.

Oct 2021

Trelleborg to supply seals to the world’s longest immersed tunnel that will connect Denmark with Germany

Trelleborg’s marine and infrastructure operation has been awarded the contract to supply its tunnel seals to Femern Link Contractors (FLC) for the construction of the 18-kilometer long Fehmarnbelt tunnel. Connecting Rødbyhavn in Denmark and Puttgarden in Germany, once completed it will be the world’s longest immersed tunnel.

Constructed from 79 large tunnel elements, each 217 meters long, and 10 special elements, the Fehmarnbelt immersed tunnel will comprise a four-lane motorway and two electrified rail tracks. Sealed by Trelleborg’s industry-leading Gina gaskets, Omega seals, Waterstop seals, and clamping systems, component supply will begin in 2022, and final deliveries are scheduled for the end of 2026.

The Fehmarnbelt tunnel is an important part of the European transport network, bringing Scandinavia and Central Europe closer together via the so-called North-South corridor. When complete, the tunnel will enable motorists to travel from Rødbyhavn and Puttgarden in just 10 minutes and train passengers in as little as seven minutes, both saving around an hour each way when compared to the current ferry crossing. The construction of the tunnel will challenge the current traffic volumes and thus reduce fuel and carbon emissions.

Richard Hepworth, President of Trelleborg’s marine and infrastructure operation, commented: “Water tightness is integral to immersed tunnels, which require high-quality sealing products, in-depth engineering, and application expertise. Trelleborg has an extensive track record for delivering high-performing seals to immersed tunnels, in Europe and increasingly in Asia, where the market for various infrastructure projects is growing strongly. As a global leader in sealing systems for immersed tunnels, we are delighted to supply seals for the construction of The Fehmarnbelt immersed tunnel, a project that will deliver a green corridor between both Denmark and Germany.”

Trelleborg’s Gina gaskets and Omega seals fit between the sectional elements of immersed tunnels to prevent water ingress due to external water pressure. Designed to handle the intense transfer of hydrostatic loads and movements between tunnel ends caused by environmental pressures such as seismic activity, soil settlement, and temperature effects, Trelleborg’s sealing systems promise a product life expectancy of up to 120 years with little-to-no maintenance.

Guided by the UN’s SDGs and a firm belief that prioritizing sustainability above everything is the right thing to do, Trelleborg has pledged a long-term commitment to enhancing sustainability by design and to creating more sustainable products, technology, and operational processes to the benefit of both the planet and its customers. In support of five of the United Nation’s goals, for Trelleborg’s marine and infrastructure operation, this commitment spans three key focus areas. These include responsible supply chains from sourcing to end-of-life, decarbonizing the maritime sector through the development of cleantech, and engineering sustainability through premium product design.

November 2021

On the 29th-day construction work began on the German side of the underwater tunnel.

Speaking at the groundbreaking ceremony in Puttgarden Danish transport minister Benny Engelbrecht described the Fehmarnbelt connection as an incredibly important construction project not only for Denmark and Germany but also for the whole of Europe.

“It is a milestone in the long history of the Fehmarnbelt connection, and I am glad that today we have put the shovel in the ground, so we are now working on both sides towards the common goal,” said the Danish transport minister.

Leave a Reply