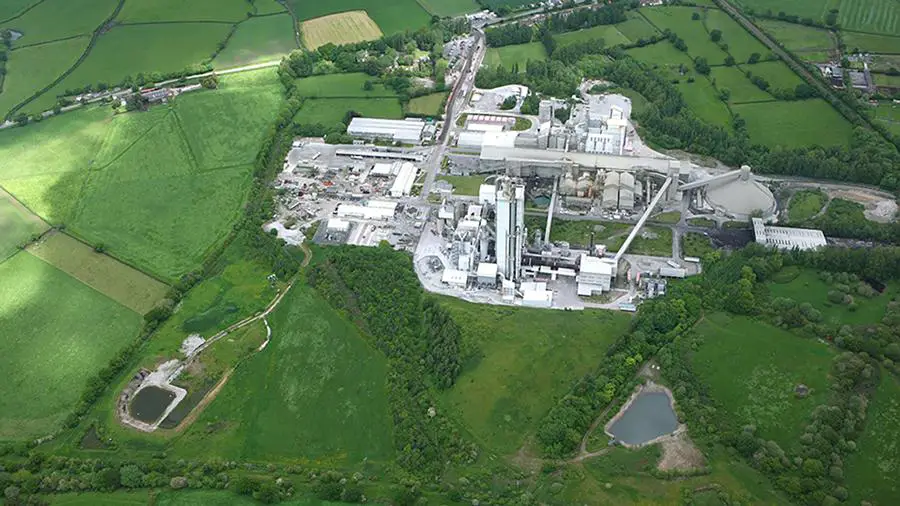

To carry out deeper study of the specifications of a carbon capture plant, located in UK’s Padeswood Cement Works at Flintshire, Heidelberg Materials UK, a leading global manufacturer in cement, is currently deploying Mitsubishi Heavy Industries, Ltd. (MHI)’s technology for Front End Engineering Design (FEED).

MHI was awarded the contract according to the progress made by the Padeswood carbon capture and storage (CCS) project planned for the area. Heidelberg Materials settled on MHI after it had worked on the initial competitive Pre-FEED project study in 2022.

Part of the HyNet carbon capture, utilization and storage (CCUS) cluster in UK’s Northwest, the project is looking to capture at least 800,000 tons of CO2 per year from flue gas. The captured gas is generated during the cement manufacturing process. The gas will be stored off Liverpool Bay’s depleted gas field.

Expected dates for the commissioning of the carbon capture plant

It is expected that the carbon capture plant will commence its operations in 2028. Facilitating the production of carbon neutral cement is important in providing support to the low carbon supply chain to the construction sector. This is a benefit of decarbonizing the industrial process.

The carbon capture plant comes as a result of a partnership between MHI and Worley. Worley will execute the plant’s basic design Advanced KM CDR Process. This is a technology based on capturing CO2 that was jointly developed with The Kansai Electric Power Co., Inc.

The cement sector’s carbon emissions are unavoidable during the process of production. This is according to MHI CEO and Head of Engineering Solutions, Kenji Terasawa.

Heidelberg Materials UK’s objective

To address the challenge of carbon emission, as well as setting an example in the country’s cement industry, Heidelberg Materials UK is expected to deploy their proprietary carbon capture technology, the Advanced KM CDR Process. The entity is dedicated to achieving net zero carbon come 2050.

The move, according to Heidelberg Materials UK’s CEO, Simon Willis, is decisive. The company is aiming to install the carbon capture technology at their Padeswood cement works plant. The carbon capture plant, when complete, is expected to offer net zero building materials for larger projects in the UK. This would facilitate their operations, working to alleviate carbon emission in the construction industry. It would also help them attain their ambition of becoming a net zero business.

Worley’s Senior Vice President UK, Marino Barbi, also mentioned that they are happy, together with MHI for their selection by Heidelberg Materials, for the Padeswood CCS FEED initiative.

According to Marino, the development is CCS’ first of its kind in the UK. He claimed that their selection is evidence of their strong relationship with Heidelberg Materials and MHI. The VP also said that the selection was based on their implementation of the pre-FEED along with the extensive CCUS capabilities of Worley.

The Government’s vision

By 2050, the Government of the UK is looking to attain net zero carbon emissions. The requisite infrastructure, which is in line with the initiative, also includes the formation of CCUS clusters. The carbon capture plant is being carried out to execute all the related processes starting From CO2 capture to transportation and storage in each of the state’s industrial zones that have been targeted.

The project is included in the HyNet CCUS cluster. In October 2021, it was chosen by the then Department of Business of the United Kingdom, Energy and Industrial Strategy (BEIS) as a site for storage. The Department for Energy Security and Net Zero (DESNZ) is also said to be supporting the initiative.

Why the project was selected by the UK Government

The Government of the UK chose the project as a specific CO2 capture and storage initiative. This was done in an effort to popularize decarbonization in the cement industry.

It is said that the MHI Group recently announced its plan to attain neutrality by 2040. Currently, the company is strategically working to reduce carbon emissions on both energy demand and the supply side.

The development of the CO2 solutions ecosystem that integrates many sources of carbon emissions, including the modes of using and storing carbon gas is said to be a core element of the entity’s Energy Transition.

MHI is expected to continue supporting the CCUS business through using its technology as well as providing solutions, being part of the team that promotes the reduction of the greenhouse gas emissions internationally. The company is also set to develop more solutions that would help preserve the environment.

Companies involved in the implementation of the carbon capture plant in Flintshire

Heidelberg Materials

As one of the biggest integrated manufacturers of construction materials as well as solutions in the world, Heidelberg Materials is one of the largest producers of ready mixed concrete and cement. The company is well represented, with offices in more than 50 countries. It is said that approximately 51,000 people have benefited from jobs provided by the company, with at least 3,000 per location.

Worley Limited

A professional services company, chemicals, energy as well as resources experts, Worley Limited partners with customers looking to deliver projects as well as creating value over their asset’s life.

The company is listed on Australian Securities Exchange, with its headquarters based in Australia. The company drives the world towards sustainable energy sources. Worley also provides chemicals, electricity as well as resources that are currently needed.

MHI Group

In partnership with The Kansai Electric Power Co., MHI Group has been developing the KM CDR Process (Kansai Mitsubishi Carbon Dioxide Recovery Process) as well as the Advanced KM CDR Process since 1990.

MHI has implemented 16 plants which have adopted the KM CDR Process by February 2024. It has two more carbon capture plants that are under construction currently.

Also read:

Construction to begin soon on largest blue hydrogen plant in UK

CF Industries Plans $2B Low-Carbon Ammonia Plant in Ascension Parish, Louisiana