Founded in 1988, ABG is a market leader in the design, development, manufacture and technical support of high performance geosynthetic systems for use in a wide range civil engineering, environmental and sustainable building projects.

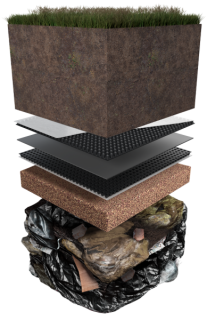

ABG’s range of geocomposites for landfill and mining applications includes the Pozidrain wide-width preformed drainage and gas venting solution. Used extensively as a sustainable, environmentally friendly alternative to traditional filter stone layers for landfill basal linings, contaminated land and mining tailing capping; Pozidrain provides drainage on slopes to remove water, liquids and gas quickly and efficiently.

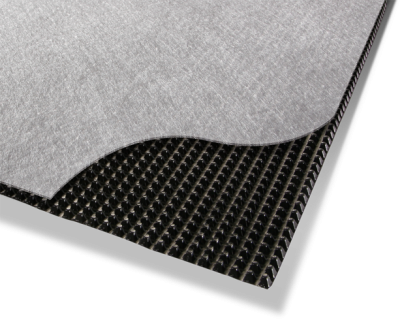

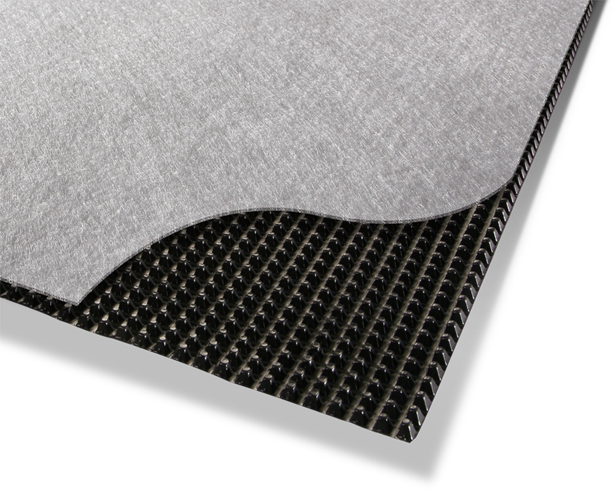

Pozidrain consists of a high strength flexible polyethylene cuspated drainage core with a non-woven geotextile filter fabric bonded onto one or both sides. The geotextile filters a wide range of materials and is bonded to the core to ensure that it does not deform into the drainage channels under the load of the back fill material. The drainage composite allows fluids and gases to percolate into the core whilst supporting the back fill material. The collected fluids are then transported along the core to a discharge point.

The HDPE core in Pozidrain forms a high-performance drainage void, using the spaces between the cuspates. This unique core design offers clear passageways which allows flow in all directions, even in the event of damage or a blockage occurring.

Impressive compressive strength and creep resistance properties ensure that the core maintains drainage capacity under a wide range of compressive loadings. Pozidrain is durable and sufficiently robust to resist the mechanical stresses imposed during installation and throughout the design life. Use of Pozidrain may eliminate the requirement for secondary protection of the geomembrane liners; thick Terrex SNW protection geotextiles may be used in the manufacture of Pozidrain to create a very substantial protection and drainage layer with just one installation cost.

When compared with aggregate drainage, Pozidrain offers superior flow characteristics in a much thinner layer. This reduces the required thickness of the landfill capping and base lining system and results in extra void space and savings.

Pozidrain is available in a variety of roll widths and lengths to suit different site requirements. To provide different flow requirements, Pozidrain is manufactured in thicknesses from 4 mm to 25 mm.

Applications

- Leachate or ground water drainage collection for landfill containments

- Drainage layer between the soil cover and geomembrane of a landfill cap

- Landfill basal drainage

- Landfill slope drainage

- Hazardous gas venting / methane venting from landfills

- Groundwater drainage/collection

- Leakage detection layers within the landfill base lining

- Vertical cut-off trenches

- Embankment drainage & reinforcement

- Slope stabilisation

- Capillary break layer in contaminated land and mining tailings treatment

- Geomembrane protection

Benefits

- Eliminates filter stone

- Creates more landfill void

- Allows use of lower specification backfill materials

- Reduces excavation and backfill

- High impact and crush strength

- High flow capacity and long performance life

- Compatible with geomembrane systems and acts as the protection layer to geomembrane liners

- Ease and speed of installation without specialist equipment

- Massively reduced traffic volumes compared to drainage stone

- Wide rolls are suited for rapid installation on large landfill and restoration projects

- Chemically inert – resistant to petrol, oils, acid, alkalis, leachate and common chemicals

Typical Client Profile:

- Landfill Engineers

- Environmental Waste Engineers

- Contaminated Land Specialists

- Remediation Engineers

- Landfill Operators

- Environmental Engineers

Case Studies:

Pozidrain drainage geocomposite has been used in the following projects:

- Coal Ash Containment Basal and Capping, Jorf Lasfar, Morocco

- Landfill Capping Drainage, Victoria, Australia

- Embankment Drainage, High Speed Rail, Sevilla – Cádiz, Spain

Related Products:

As well as Pozidrain ABG manufacture Pozidrain G which is a permeable geocomposite drainage layer, and Pozidrain Protector which provides geomembrane protection and drainage in a single layer. Pozibreak provides a capillary break layer, and is also used as a salt barrier.

Associated System Products

Within a drainage system where Pozidrain composites are used, the following products are often used as part of the construction profile:

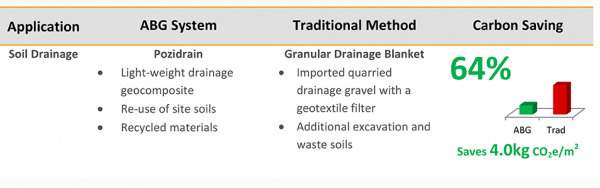

Soil Drainage – Carbon Footprint saving

The use of ABG Pozidrain Drainage Geocomposite can save up to 64% on the carbon footprint compared with traditional granular soil drainage methods:

Click to read the full carbon footprint assessment

Leave a Reply