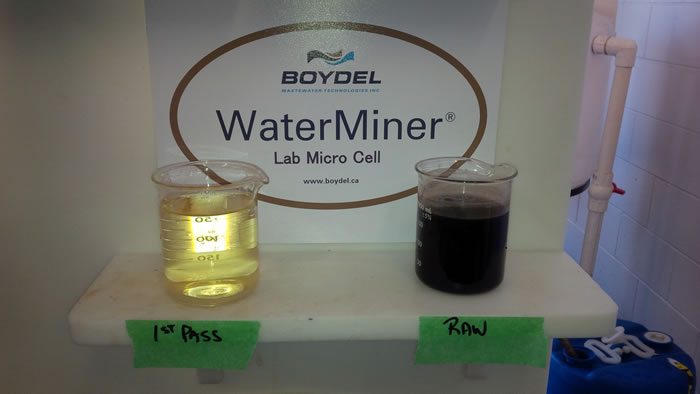

Electro-coagulation is a method involving the destabilization, coagulation and oxidation of visible and invisible contaminants in to a floc that can be removed from the water. The method carries the promise of reducing costs, improving contaminant removal on wastewater treatment, delivering high performance and solving many of the opex and performance problems associated with biological treatment options. Among issues at the center of widespread implementation of electro-coagulation as a mainstream wastewater treatment method included improved electrode reliability, performance stability, predictability and overall reactor design. Boydel has confirmed these improvements in its WaterMiner®.

BOYDEL was founded in Canada and patented globally. Their products core technology derives from the late 1800’s technology called electro-coagulation. Boydel has solved many conventional EC system mechanical issues and added, for the first time ever, an in situ new Electro Advanced Oxidation (EAO) capability – which further oxidizes many of the new emerging contaminants.

Boydel has been redesigning and refining its WaterMiner waste water treatment process technologies as an R&D company and technology licensing company. Compared to chemical-biological techniques, their automated electrochemical, plate free, hybrid ELECTROCOAGULATION-ELECTROADVANCED OXIDATION (EC-EAO) technology produces only 10-20% of the sludge.

The technology helps improve performance and decrease mass loading of current biological technologies if applied as a pre-treatment and it can be expected to help reduce maintenance costs on biological media and membrane plant systems. It helps solve problems associated with operating biological treatment methods in heavy TSS mixed commercial and industrial flow wastewaters. WaterMiner®achieves its full treatment potential in a 15 minute retention time.As a packaged plant the plant start-up is – “Roll Up and Run™”.

Boydel provides the products in North America and China. According to the President Randy Deluca, Boydel is also patented in South Africa and in a few MENA states. Randy adds that Boydel is also interested in developing distributorships in Nigeria, Rwanda and other states.

Compared to chemical-biological treatment systems, the technology can achieve an 80-90% less sludge production and the sludge is 90% sterilized and very stable. Further, the Boydel method does not produce Carbon Dioxide or Methane, and can be upgraded.

The system can treat septage or sewage waste water to deliver clear disinfected, 90% plus phosphate free water in tens of thousands gallons/day (700,000 litres/day) for a single platform; with maximum treatable flows unlimited by simply adding platform modules.

Contributor,

Randy DeLuca

President

[email protected]

www.boydel.ca/

Leave a Reply