Toyota has started construction of a $531 million rear axle production plant at its South Side facility, bringing in-house the production of drivetrain components for Sequoia SUVs and Tundra pickups built in San Antonio. Toyota will also ship the assemblies to Mexico for its Tacoma truck line.

“Our new plant will export sixty percent of its products to our facilities in Baja California and Guanajuato,” said TMMTX President Susann Kazunas.

Toyota will move work from a Midwest supplier to San Antonio, according to Toyota Motor Manufacturing Texas President Susann Kazunas.

“For me, this new plant demonstrates our team’s capability,” she said Wednesday, suggesting possible future expansion.

The axle factory is set to add, over 400 positions to its workforce and bring the number of employees at the plant to more, than 4,000 individuals The company plans to equip the new 500,000 square foot facility with five production lines and 200 welding robots to manufacture 18 different types of rear axles.

Read also: Plans Announced for US$ 50M Toyota Electric Vehicle Battery Lab in Michigan

When will production at the factory begin?

The Japanese car maker says it will start making axle assemblies at the end of next year. Targeted to make 500,000 units a year when at full capacity by first quarter of 2027. Toyota is already recruiting for skilled maintenance positions. Onboarding for production personnel is expected to begin in late 2025 and continue through 2026.

Toyota expects the new axle assembly unit to streamline production, improve quality control, reduce lead time, and lower costs.

“Some might think San Antonio lacks manufacturing history in the United States,” Kazunas said. “Some might expect workforce hiring challenges, but I disagree. We have an excellent plan and all the necessary talent here.”

Key note: Toyota considered other markets for the new rear axle plant.

Read also: Rivian Chooses Construction firm to build their planned $5B EV factory in Georgia

Texas-Mexico Automotive Supercluster

Bexar County Commissioners last year approved an initiative to develop a Texas-Mexico Automotive Supercluster to compete with other major automotive manufacturing regions.

Currently, TMMXT now covers 2.2 million square feet. Toyota has invested $4.2 billion in the plant to date.

Toyota Rear Axle Production Plant Project Factsheet

Project Overview

Project: New Rear Axle Production Plant

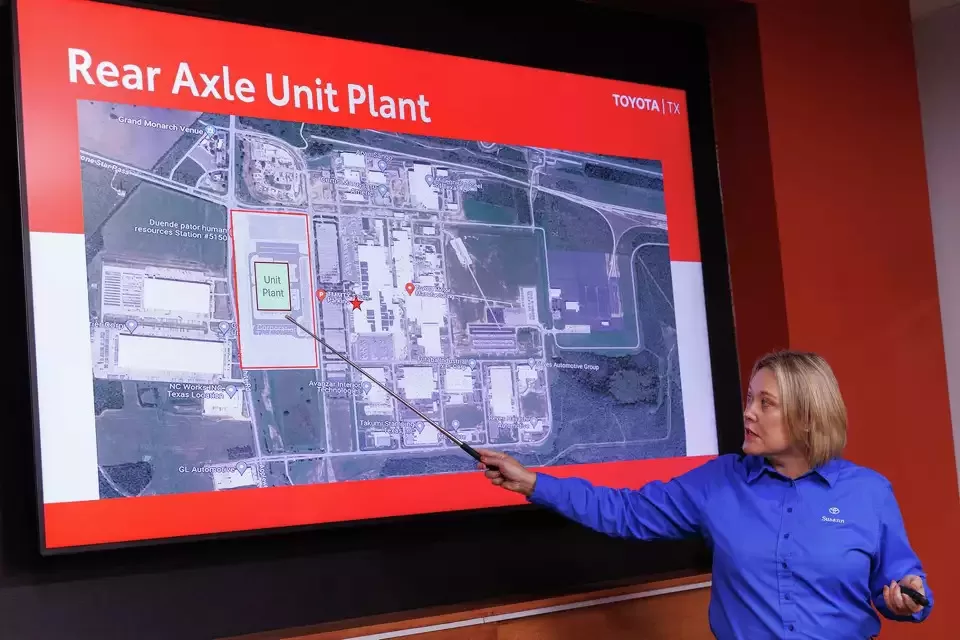

Location: Toyota Motor Manufacturing Texas (TMMTX), South Side, San Antonio

Total Investment: $531 million

Parent Company: Toyota Motor Corporation

The New Plant Specifications

Size: 500,000 square feet

Production Lines: 5

Welding Robots: 200

Product Variations: 18 different rear axle types

Production Capacity: 500,000 units annually (at full capacity)

Employment Impact

New Jobs Created: 400+

Total Plant Employment After Expansion: 4,000+

Construction timeline for the new rear axle production plant

Construction Start: 2024

Production Start: Late 2026

Full Production Capacity: Spring 2027

Production & Distribution

Primary Products: Rear axle assemblies for:

Toyota Sequoia SUVs

Toyota Tundra pickups

And Toyota Tacoma trucks

Distribution:

40% for San Antonio plant use

60% export to Mexico (Baja California and Guanajuato facilities)

Technical Capabilities

In-house production of drivetrain components

Quality control improvements

Streamlined production processes

Reduced lead times

Cost optimization

Read also: Ground breaks for electric vehicle (EV) battery giga factory in Kokomo, Indiana

The new rear axle production plant in San Antonio

Campus Size: 2,000 acres

Current TMMTX Facility: 2.2 million square feet

Total Toyota Investment in TMMTX to date: $4.2 billion

Strategic Significance

Brings previously outsourced production in-house

Strengthens Texas-Mexico automotive corridor

Enhances San Antonio’s manufacturing capabilities

Creates potential for future expansion

Supports Texas-Mexico Automotive Supercluster initiative

Supply Chain Impact

Relocates production from Midwest supplier

Establishes new role in Toyota’s North American supply chain

Improves vertical integration

Enhances cross-border manufacturing coordination

Read also: $300 Million Upgrade to Amtrak’s Maintenance Facility at the King Street Coach Yard

Leave a Reply