SKF has developed a new generation of highly effective and easily maintained shaft seals that can prolong the service life of heavy-duty equipment operating in difficult conditions.

From wind turbines to underground mining machinery, shaft seals frequently provide the first line of defense between the external environment and critical bearings and gearbox components. These seals often play a dual role too: protecting components from contamination and stopping lubricants escaping into the environment. Now engineers at SKF have developed a new generation of seals – the HRS range – specifically to meet the challenges faced by designers, manufacturers and operators of equipment working in some of the toughest places on Earth.

Light, compact and versatile

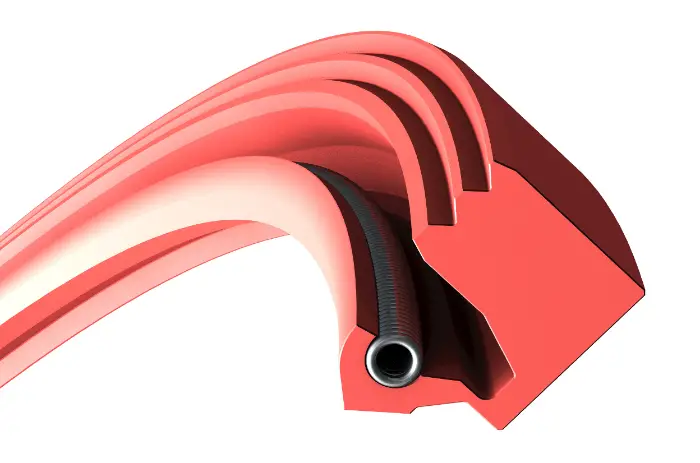

The machined polyurethane HRS seals weigh less and take up less space than existing labyrinth seal designs – a characteristic appreciated by equipment manufacturers looking to maximise space utilization and minimize the weight of turbine nacelles, for example, or to minimise the overall package size of mining and construction equipment. They are available in three standard designs to suit different applications. The HRS1 seal is designed to keep lubricant inside bearings and gearboxes, while coping with the large misalignments often experienced in this kind of equipment. Depending on the size of the shaft, HRS seals can accommodate coaxial misalignment of up to 3mm. For applications where protection from contamination by dust or moisture is also a priority, customers can add the HRE excluder seal to the HRS1, providing an additional external lip. Alternatively, they can use the HRSA version of the seal, which incorporates an auxiliary lip into its design.

The HRS seals are manufactured from G-ECOPUR polyurethane, which is an ozone, UV and water-resistant material that offers excellent wear resistance compared with the rubber materials commonly used elsewhere. In tests, the G-ECOPUR has proved to be five times more abrasion resistant than the next best performing elastomer material, a characteristic that translates into longer service life and less chance of premature failure due to wear. G-ECOPUR also allows the HRS seals to be machined with an exceptionally smooth surface. The seals’ smooth outer surface, meanwhile, also prevents the leakage of lubricant between the seal and housing, a condition that commonly affects rougher phenol-impregnated fabric seals.

“Seals often aren’t a high priority item for equipment designers,” says Andre Weyers, Seals Product Manager at SKF. “However, they have a high impact on system performance, which is why they have been an important area of focus for SKF. The new HRS machined polyurethane seals have been developed to deliver exactly what industry needs: greater reliability with reduced maintenance requirements in a cost effective package. When seal replacement is eventually needed, these seals offer a quick, easy and safe solution.”

Simple to install and maintain

The whole HRS range is available in solid or split designs. Solid seals are designed for installation during manufacture where operators can access the end of the shaft. Split seals are ideal for in-service replacement, or manufacturing applications where there is no access to the end of the shaft. The smooth outer diameter of the HRS seals also makes them easier to install than fabric reinforced seals, saving time and cost in manufacture or replacement.

Carefully optimized seal geometry means the sealing lip cannot contact the seal carrier, therefore minimizing the risk of inverting the seal or losing the stainless steel garter spring during assembly. Meanwhile, the design of the seals themselves, along with the use of stiffer materials further simplifies installation, saving up to four working hours per seal compared with alternative fabric reinforced designs, as sometimes seen in the two point suspension wind turbine

For maintenance and repair applications, the split HRS seals are provided in special transport packaging that contains the installation instructions and all the materials necessary to complete the job, a boon for service teams working in cramped and remote conditions.

Wide availability

HRS seals are manufactured in a full range of standard sizes to suit heavy-duty applications in a range of industries including wind energy, cement manufacture, mining and tunnel boring equipment. As they are manufactured using a machining process, rather than by moulding, HRS seals can also be easily modified to meet specific customer requirements. The seals are already available through SKF’s worldwide distribution network, helping to support manufacturers and operators that are working on an increasingly global basis. They can also be supplied as part of an integrated SKF solution that includes bearings, seals and lubrication.

Leave a Reply