Far away from the world’s well-known diving paradises, the Polish city of Mszczonów has become home to what is currently the deepest diving pool in the world. Numerous PERI systems were used for the construction of the pool, which has a depth of up to 45.50 meters. The special highlight was the dismantling of the ST 100 Stacking Towers used: for reasons relating to the static requirements, the stacking towers could only be dismantled after the pool had been filled with water – not by the company’s own construction site staff, but by specially trained divers.

Near the Polish capital Warsaw you can find Deepspot, currently the deepest multi-zone simulator on the diving scene. Deepspot offers divers optimal conditions to pursue their passion away from the world’s oceans: always perfect weather, clear and warm water, as well as an exciting underwater world with a boat wreck, underwater caves, a glass-enclosed underwater footbridge sloping walls and ropes, for an experience that rivals the hustle and bustle of the oceans. Regardless of whether one is a beginner or experienced diving professional, scuba diver or freediver – everyone gets their money’s worth here. Deepspot opened to the public at the end of 2020 after a construction period of around two years.

Multi-zone simulator with two areas

The Deepspot diving facility is divided into two areas, the main part with a depth of 15.50 m and a diving tube with an additional depth of 25.00 m, which connects to the main area at one edge of the pool. The tube depth is roughly equivalent to the height of a 15-storey building and holds a total of 8,000 m³ of water, which is roughly equivalent to the water volume of 27 Olympic-sized swimming pools. In addition, 4.5 m extends above ground level.

Static challenge of the highest order

From a static point of view, the difficulty of building this submersible system is comparable to building an underground system. The static system of the pool is composed of a reinforced concrete floor slab, load-bearing walls with reinforced concrete piers and monolithic slabs. A variety of geometrically and technologically complex PERI Formwork solutions were used which were delivered pre-assembled to the construction site. The sloping walls of the diving pool were constructed with pre-assembled elements of TRIO Panel Formwork, while pre-assembled VARIO GT 24 Girder Wall Formwork was used for the circular diving tube.

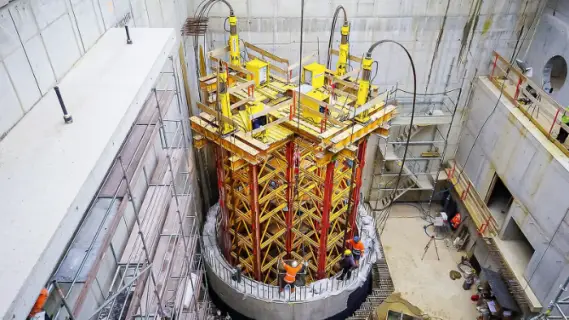

Concreting the diving tube

The deep diving tube with an internal diameter of 7.00 m and a foundation depth of 40.50 m below ground level posed the greatest design challenge. The concreting of the pipe rings with an outer diameter of 8.50 meters was carried out using monolithic construction in steps of 4.00 meters each.

The 25-metre-deep shaft is divided into 4-metre-long segments. A hydraulic cylinder supported on VST Heavy-Duty Towers assisted this process: “The vertical alignment of the tube of the first stage shaft was the key to success here, which involved the use of special guides. The individual segments weighed 300 tones each. A total of 5,000 m³ of concrete was used,” explains the responsible Design Engineer Krzysztof Tyborowski from PERI Poland. “Non-axial and irregular settlement along with the collision with jet grouting elements were a great challenge for the structural designer of the construction. A hydraulic unit was implemented to master this challenge by securing the precision of lowering of the first stage”, Tyborowski continues. Further segments settled downwards by their own weight. The process was repeated until the deep well reached its total depth of 25 m.

Strict safety precautions

Already during the planning phase, the responsible PERI engineers paid attention not only to the static feasibility but also to the safety of the site personnel. The used and pre-assembled PERI systems, as well as the selected concreting procedure, ensured that work was carried out safely at all times – even in the great depths of the diving tube.

Quick and safe dismantling of the ST 100 Stacking Towers underwater

In addition to the diving tube, the underwater viewing bridge is also one of the highlights of the Deepspot diving system. The bridge only becomes self-supporting when the pool is filled with water and the necessary buoyancy force is fully present. For this reason, it was necessary to support it with shoring until shortly before the pool was commissioned.

It was decided that ST 100 Stacking Towers with a height of 14.40 m, would be used to ensure safe load transfer. The dismantling of the stacking towers could only take place after the pool was filled with water. Professional divers were hired for this task, and in a total of ten hours they dismantled the scaffolding material, which weighed a total of 3,400 kg, under water and brought it safely to the surface.

Leave a Reply