Trelleborg’s marine and infrastructure operation and shipping and logistics company, Nippon Yusen Kabushiki Kaisha (NYK Line), have announced a strategic partnership to meet the demand for increased safety, efficiency and sustainability of mooring operations across Japanese ports. Under the new agreement, NYK Line will act as Trelleborg’s agent in Japan, and as a consultant via its subsidiary Japan Marine Sciences (JMS), to help ports across the country realize the benefits of Trelleborg’s safety focused dynamic mooring solution, DynaMoor.

Hiroshi Kawagachi, Head of NYK’s Dry Bulk Transport Quality Group, said: “A demanding port environment requires that users of mooring systems adapt and innovate. We’ve long championed the criticality of the role of docking and mooring in optimizing the efficiency, safety and sustainability of the many Japanese ports at which our vessels berth. Boosted by our strategic partnership with Trelleborg and the capabilities of its DynaMoor solution, we look forward to working with Japanese ports to achieve exactly that.”

Richard Hepworth, President of Trelleborg’s marine and infrastructure operation, says: “Our strategic partnership with NYK Line will enable Japanese ports to realize the immediate need for increased mooring safety and efficiency. What’s more, it will also contribute to the decarbonization of the maritime sector globally by facilitating more sustainable mooring operations, which is a strategic focus for Trelleborg through the development of cleantech and premium product design, as part of its commitment to supporting the United Nation’s 17 Sustainable Development Goals (SDGs).”

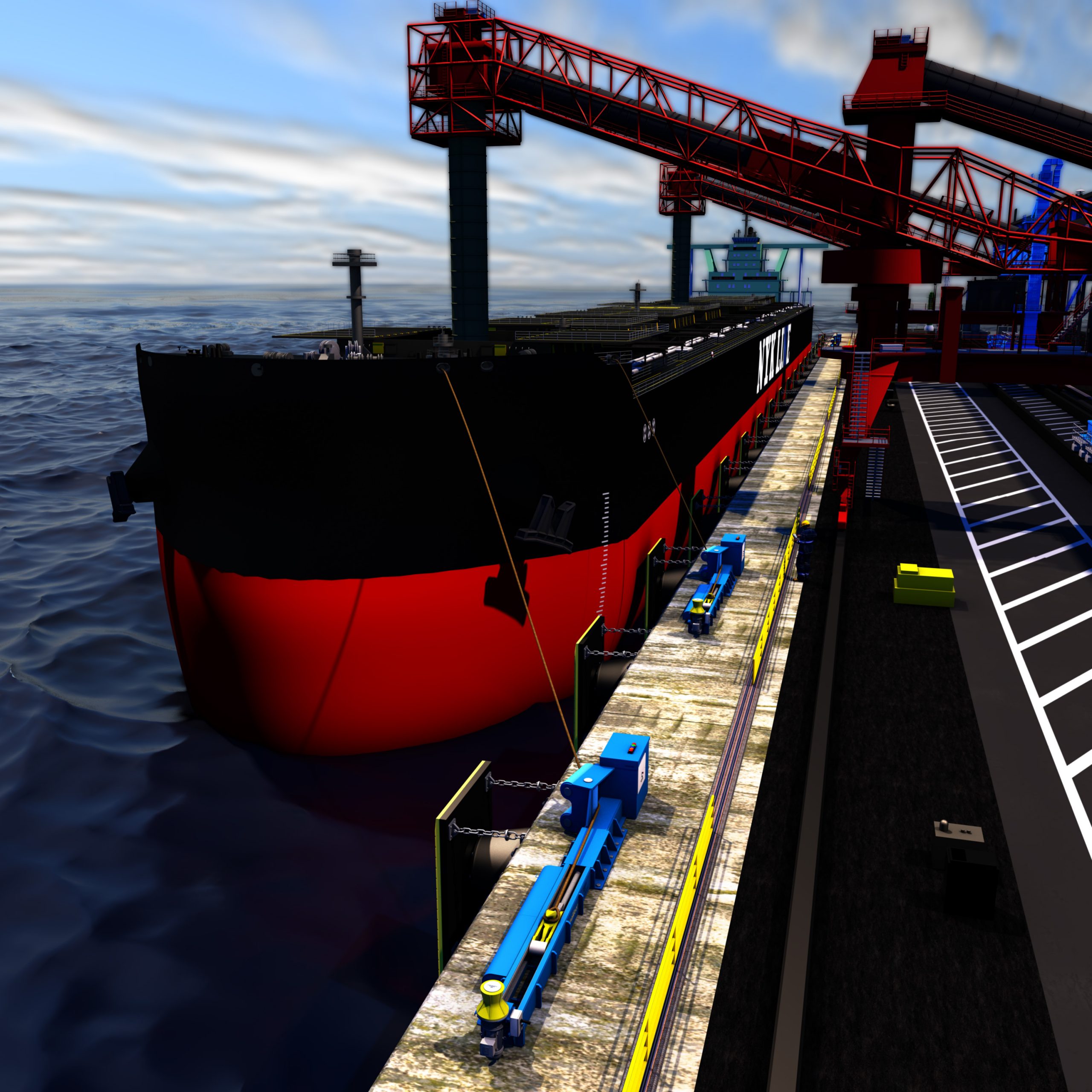

DynaMoor actively maintains tension in mooring lines to dampen vessel movements, eliminating the effect that passing ships, sea swell and long-period waves have on moored vessels. This increases the range of environmental conditions in which cargo can be transferred, improving throughput. The risk of parted lines and excessive vessel excursion is significantly reduced, protecting people, assets and increasing uptime. It further enhances safety by minimizing ‘snap back’ zones. Additonally, it is easy to set up and being independently anchored, does not rely on other wharf furniture to operate, simplifying day-to-day operations. The system speeds up the berthing process and minimizes workload and manual line handling, in addition to improving the efficiency, and reducing the fuel consumption and emissions of vessels. Thus, enabling more sustainable mooring operations.

Trelleborg’s DynaMoor solution is SmartPort enabled and so has the ability to connect with other port assets, allowing port operators to analyze asset performance and apply data insights, to improve day-to-day decision making.