Safe and cost effective options

The ‘conventional’ wood utility pole may still be the top priority for African utilities but it won’t be for too long it seems. Alternative products like steel and composites are growing in stature at an incredible rate.

State-owned corporations in African countries are in a race – in fact, desperate – to bring the supply of electricity and telecommunications services to new economically strategic regions, though beset with capacity limitations. And this mandate has to be executed in line with current environmental, health and safety, and social economic objectives. For the most part, amongst a list of vital issues, the products used in the projects, like utility poles, have to meet these requirements.

Given the traditional wood pole’s limitations in meeting the requirements, convenient and cost effective alternatives are being sought and developed.

In an interview at Construction Review’s Johannesburg office, Ian Braid, a technology consultant from Baybridge Investments, highlighted three important issues – transportation, safety and high installation costs – which render wood poles the least attractive.

“Wooden poles are heavy, which makes them expensive and cumbersome to transport over long distance. You are talking about remote areas in Africa where the road infrastructure is very poor or nonexistent.”

On the other hand, says Braid, comparatively, composites (with special reference to the brand Baybridge Investments distributes) have longer service life (zero maintenance), safe, nonconductive, theft proof, over and above, their low weight and high modularity allow for easy installation and transportation.

11 metre wood shortage justify alternatives

Five South African companies involved in electrification projects in Africa that Construction Review contacted revealed shortage of 11 metre wood utility poles. Beyond doubt, this opens the door for alternative poles.

An interesting development has been unfolding. Increasingly, steel and composite versions are being specified (recommended) as products of choice in projects.

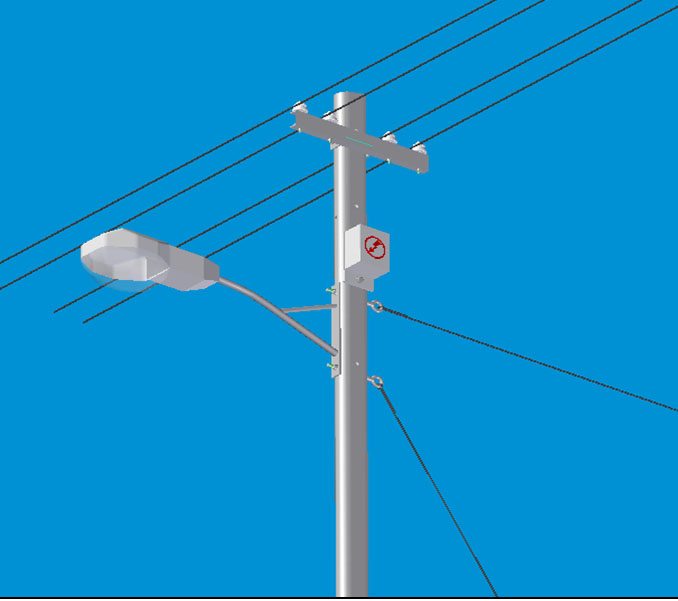

Steel utility poles

Hercules Rossouw, an authority on steel poles from StructaTechnology, a South African manufacturer exporting into Africa, believes steel poles offer greater versatility than ‘conventional’ wood poles. In association with Macsteel Tube and Pipe, the company developed the 200/240 Range Steel pole which has been supplied to South Africa’s Eskom, as a viable alternative to concrete and wooden poles.

However, alternative does not mean that standards are disregarded or compromised, clarifies Rossouw. “As a standard, all products have to be designed to SABS requirements and highest possible international standard.

“Additionally, to enhance durability, steel poles are hot dip galvanised according to SANS 121 and SABS 1461. This also makes them aesthetically pleasing.”

The durability of the product is proof-tested by the respective utility, he says. “We have used this pole for Eskom as a viable alternative as well as the Power Utilities in Namibia and The DRC.”

Using the Structa steel utility pole as a model it’s hard not to notice the features that were incorporated in the design. The masts are manufactured from thin-walled steel tube with an optimized cross section giving strength where required.

To accommodate adaptability, the steel utility poles can also be designed to allow for different configurations of phase carrier and also stay cable attachments (masts are planted in a similar manner as the wooden poles), says Rossouw. No field modification or adaption is therefore required.

By and large, steel utility poles offer the following advantages:

· No on site drilling or cutting required due to universal preparation, no on site preparation

· Earthing advantage by virtue of steel material.

· More difficult to cut, hence giving anti-theft advantage, enhancing cable security

· Universal hole set allows various standard applications

· No shortages of raw materials.

· Environmental advantage in that critical green plantations are maintained.

· Controlled production process resulting in consistent quality.

· No maintenance during life cycle, life cycle advantages e.g. fire proof, rot proof

· Veld-fire damage limited.

· Much lighter pole (typically 1/5th of wood) handles much easier with less hands

· Transport advantage gained through lighter, consistently shaped pole.