In the modern construction industry, high-performance concrete is highly valued for its excellent strength and durability. The success of this material largely depends on the quality of the aggregates used as a key foundational component.

Composition of Concrete

Concrete is a composite material made up of cement, aggregates (such as gravel or sand), water, and a suitable amount of admixtures (like fly ash or slag powder). Aggregates play a crucial role, directly affecting the strength, durability, and lifespan of the concrete.

Types of Aggregates

Common aggregate materials include sand, gravel, basalt, granite, pebbles, and feldspar.

Aggregates are classified by size into:

- Coarse Aggregates: Typically gravel or crushed stone, with particle sizes greater than 4.75 mm. They bear the main load in concrete and significantly impact its strength and compressive performance.

- Fine Aggregates: Mainly sand, with particle sizes smaller than 4.75 mm. They fill the voids between coarse aggregates, increasing the density and impermeability of the concrete.

The selection and processing of aggregates depend not only on their physical properties but also on the availability of regional resources. Coastal areas may prefer to use marine sand, while mountainous regions might utilize granite and basalt more frequently.

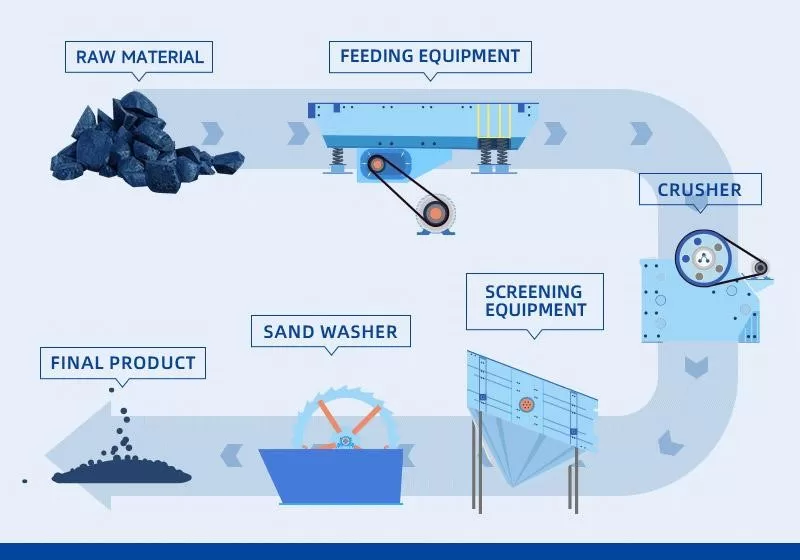

Aggregate Processing Flow

As the demand for high-performance concrete grows in the construction industry, aggregate processing technology has advanced significantly. Modern aggregate processing plants use cutting-edge crushing, screening, and washing equipment to enhance the overall quality and consistency of the aggregates.

Different countries and regions have varying technologies and applications for aggregate processing. For instance, Europe leads in environmentally friendly aggregate production, while Asian countries excel in large-scale production and application of aggregates.

Producing high-quality aggregates involves several key steps:

- Raw Material Selection: Choose the right type of rock based on the required aggregate, such as granite, basalt, or pebbles. High-quality raw materials are the foundation of high-quality aggregates.

- Primary and Secondary Crushing: Raw materials undergo primary and secondary crushing to reduce particle size. Primary crushing usually uses jaw crushers, while secondary crushing can use cone crushers or impact crushers. This process produces well-shaped aggregates with proper grading.

- Screening and Classification: Crushed aggregates are screened through vibrating screens to separate them by particle size into coarse and fine aggregates, meeting different concrete mix requirements.

- Washing: To remove dirt, dust, and other impurities from the aggregate surface, the screened aggregates are washed using sand washing machines.

- Graded Stockpiling: Cleaned aggregates are graded and stockpiled according to size for easy transport and use.

- Storage and Transport: High-quality aggregates need proper storage to prevent moisture or contamination and must be efficiently transported to concrete batching plants.

In numerous iconic construction projects, carefully selected and processed aggregates have played a key role in enhancing concrete performance. Whether in bridges, high-rise buildings, or large infrastructure projects, high-performance aggregates have proven indispensable in achieving engineering feats.

Looking ahead, with the continuous emergence of new materials and technologies, the aggregate processing industry will keep exploring more efficient and environmentally friendly production methods.

Ongoing research into aggregate performance will further promote sustainable development and innovation in the construction industry, supporting the creation of greener, smarter, and more durable building structures.