Aging gas turbine HMI hardware will eventually become a burden on plant operation. Obsolete HMIs can cause problems with connectivity, historical data loss, and hardware failure. As the hardware ages, the availability of replacement parts decreases and the cost for these parts increases. Hard-to-find motherboards with archaic ISA slots and obsolete ISA ARCNET cards can make upkeep of these machines very difficult and costly.

There comes a time when replacing the entire gas turbine HMI becomes a necessary and viable option, particularly when considering reliability and maintenance costs.

Site Layout

Recently, a peaking power plant replaced its aging gas turbine HMI system. The site had two GE Frame 6B gas turbine generators controlled by two GE Speedtronic Mark V control systems.

These units were used for fast-dispatch peaking operation and typically were started every day during summer peak, running for 3 to 4 hours each day. There were two local and one remote DOS operator interfaces. The existing Mark V Stagelink network architecture had three s, configured such that each was able to communicate with both of the Mark Vs .

Ready for an upgrade

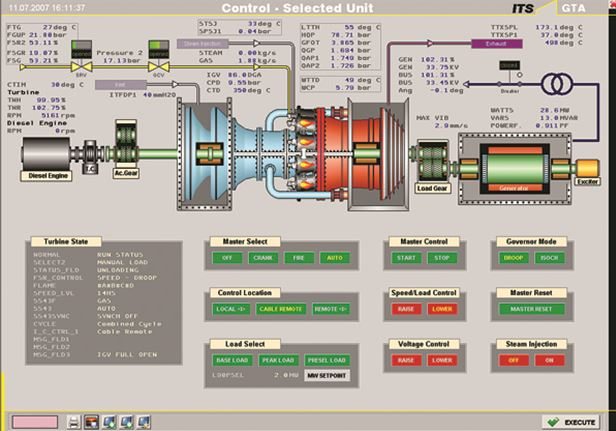

The customer’s existing gas turbine HMI network was badly out-of-date, hard to use, and suffered from significant operational limitations. Courtesy: Turbine Technology Services

The existing was a product of the 1980s and was designed in the DOS operating system. This obsolete technology had quite a few hardware and software limitations. The software was no longer user friendly and offered no historical data storage (historian) capabilities. The driver for the replacement was that the equipment was so old it was failing and the units could not be operated easily without this interface.

This impacted the customer’s ability to dispatch the units. All of the hardware components in the were obsolete, and migrating the software to a modern PC environment was very difficult.

Although the old system was being completely replaced, the customer needed all of the functions from the original to be carried over to the new system. The customer also required:

■ Easy access to tools such as EEPROM download, dynamic rung display, logic forcing, and valve calibration.

■ Off-the-shelf, commercially available hardware.

■ Display screens equivalent to the existing ones, with all important data displayed and easily viewed.

■ Accurately time-stamped alarms and diagnostics, readily available for troubleshooting.

System Design

The upgraded gas turbine HMI system was built around the Turbine Monitoring System (TMOS) available from Turbine Technology Services Corp. (TTS). All of the existing tools were included in the new software. In TMOS, EEPROM download, dynamic rung display, sequence editor, logic forcing, valve calibration, pre-vote data display, control constant adjust, IO configuration, and ARCWHO are all Windows-based functions and easy to operate.