The production control of thick-walled spiral submerged arc welded steel pipe is mainly to improve the plastic toughness of the steel pipe, improve the cleanliness of the molten steel, reduce harmful inclusions, and improve the overall quality of the steel pipe. In the production process, a reasonable cooling system is adopted to avoid cracks inside and improve the quality of the steel pipe from various aspects.

Controlling heating temperature

The heating temperature is reasonably controlled during the production process, and the optimum heating temperature is selected by measuring the thermoplastic curve. Tube billet heating should also pay attention to sufficient holding time to reduce deformation resistance and improve the plastic toughness of 45# structural thick-walled spiral tube.

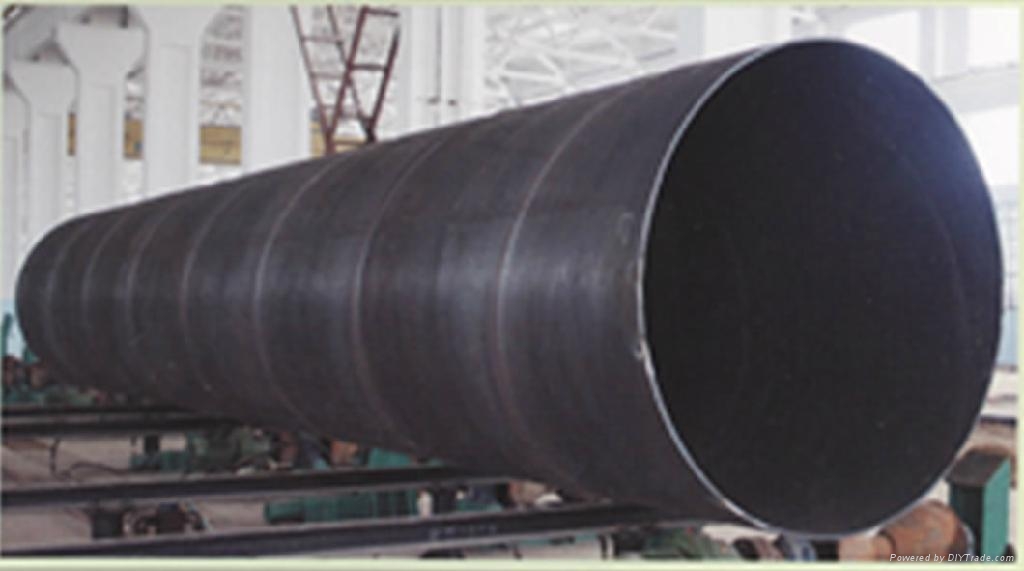

Large-diameter spiral steel pipe is a general term, generally refers to a spiral steel pipe with a diameter of more than 1 meter. The spiral steel pipe is formed by bending a steel strip and then welded, and the seamless steel pipe is perforated with a steel billet and there is no welded joint on the square pipe.

The steel pipe is subjected to experiments such as water pressure, bending and flattening, and has certain requirements on the surface quality. Usually, the delivery length is 12 meters, and the fixed delivery is often required. The specifications of the spiral steel pipe are expressed by the nominal diameter (mm). The nominal diameter is different from the actual one. According to the specified wall thickness, there are two kinds of ordinary steel pipes and thick steel pipes.

The production process requires more procedures. The final step is to reduce the roll speed. The roll speed is the key parameter of the piercing process. During the change of the roll speed from low to high, there is a critical roll speed at which delamination begins. When the roll speed is low, the tube blank is easy to form a cavity; when the roll speed is high, the tube blank and the 45# structure spiral steel pipe are easy to form delamination defects. In order to eliminate the layering defects of the tube blank and the 45# structure spiral steel pipe, the roll speed should be reduced below the critical roll speed at which delamination begins to occur.

Storage methods

The storage methods of steel pipes are closely related to their service life. Consumers need to properly store the steel pipes. The staff of the steel pipe manufacturers also share with you the correct storage method. First, we need to store the steel pipes in the warehouse. Do not store in the open air. It is necessary to ensure that the storage warehouse is clean and tidy. At the same time, there must be a good drainage environment. If there are weeds or other debris on the ground, it needs to be cleaned and stored. This is to keep them clean. Corrosive gases can corrode spiral steel pipes.

And the contact of acid, alkali, salt and other materials with steel pipe will also have corrosive effect, so we need to do a good job of protection and avoid contact with these substances. We also need to do classification work during the storage process. In order to avoid the inconvenience of use, we also need to check the steel pipe regularly. If it is found that the spiral steel pipe is rusted, we also need to remove the rusted product in time, and analyze the cause of the corrosion, and avoid other by correct treatment. Corrosion of steel pipes.