Modular Construction refers to one or more structural units that are assembled or fabricated in a manufacturing plant away from the job site and is then transported and assembled on-site. All the modules are prefabricated with trim work and MEP system installed.

Modular Construction provides many benefits such as reduction of the need for workforce, reduction of on-site House Green Gas emissions, and improvement of the construction schedule and product quality.

Benefits of BIM in Modular Construction

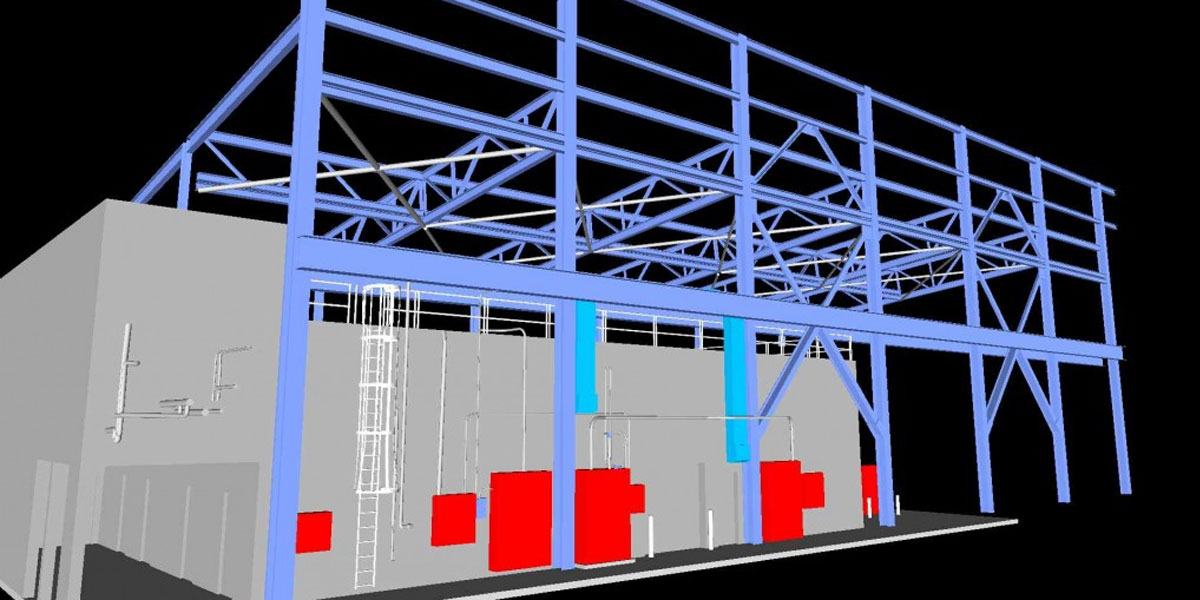

Building Information Modeling (BIM) is a 3D Modeling process that improves planning, design and construction of the buildings with this it benefits and portrays impact on off-site construction.

- BIM acts as the integration for Modular Construction based on production, execution and development of prefabricated panels.

- BIM helps the construction professionals with insights and tools to efficiently plan design and construct the building and infrastructure while maintaining it.

- It enhances the communication flow among project participants and improves the design and construction process. BIM has made coordination and fabrication of MEP components in Modular Construction be easy and operate smoothly.

Facilitates shop drawings of MEP discipline

BIM facilitates fabrication and shop drawings of MEP components in less time and accurately for the building project. It enables digital design flow to fabrication workflow easily for all the disciplines.

With the use of BIM Modeling Services in Modular Construction, use of prefabricated modules is increased along with resolving all the potential issues in the design stage itself, saving time and money on the project.

Control on the final product is higher with the advent of BIM technology.

How Architects can benefit from Modular Construction

Architects will be able to use the Modular Construction standards to size and locate the building object in a modular reference frame that would increase the use of BIM application for the built environment in the prefabrication industry.

Collaboration with BIM in Modular Construction

BIM analyzes the exact data of the site with collaboration and gives precise measurements of the prefabricated modules to sub-contractors. It thus enables the perfect fitting of components in the building without leakages.

BIM allows transportation of feasible space for the modules so that they can be viewed in the 3D model and set the modules in place to have efficiency and problem can be solved easily.

Materials at the off-site construction can be effective and efficient if undergone proper surveillance by using BIM through videos and measurements of the modules.

A designing team must check that the BIM integration in modules is inter operable with the software used by prefabrication. Prefabricated elements must be delivered to a job site on time.

The following process is carried out by implementing BIM in Modular Construction:

It can create a 3D model for the representation of building modules, geometry and space for related systems. Code compliance’s reviews data is embraced with a 3D Model by fire and building officials.

Once the BIM model is completed, it can easily produce the detailed fabricated shop drawing of the building components. Building system interference can be visually presented.

Challenges of BIM in Modular Construction

Due to modules being transported from one site or factory to another, it becomes problematic for the materials to be inspected during off-site construction.

Wastage of wrong prefabricated elements can be reduced or eliminated if used by the integration of BIM technology for modularization of the building.

MEP BIM Coordination Services are one of the essential benefits that BIM provides with integration with Modular Construction. BIM application helps to generate accurate size and space location of the prefabricated modules to ease the process smoothly.

Detailed prefabrication drawings produced in BIM software helps to review and coordinate work between trades along with resolving the issues within drawings. Production of components starts once the coordinated prefabrication drawings are prepared and complied.

Great to see BIM making headlines again. I wonder whether the use of reality capture could also benefit modular construction by showing the design team a highly accurate picture of the space they need to create prefabricated modules for.

Hello I read your blog regarding about the Role of BIM in Modular construction so that good one topic and i really thankful and the content is also informative. So keep it up your BIM content like these and get the more content about the BIM or MEP.