Sheet metal is a fundamental player in construction, quietly shaping the foundation of structures we encounter daily. Its importance lies in its durability and versatility, making it a preferred material for various applications, from roofing to structural components. However, the real test for sheet metal emerges in extreme conditions. Harsh weather, corrosive elements, and high-stress environments present challenges that demand robust solutions.

In the construction landscape, understanding and overcoming these challenges is a necessity for ensuring the long-term durability and integrity of structures. This blog explores the practical aspects of sheet metal, discussing its importance and addressing the formidable challenges it encounters in the demanding realm of extreme environments.

Sheet Metal Basics

Sheet metal is a versatile material extensively employed in construction for various applications. From roofing to ductwork, it serves a multitude of purposes due to its durability and malleability. In construction, sheet metal is commonly used for its ability to be bent, cut, and shaped into precise forms, making it an ideal choice for projects where precision matters.

Nature’s Impact

Weather poses formidable challenges to sheet metal in extreme environments. Harsh weather conditions, including intense heat, freezing temperatures, and corrosive elements, can significantly impact the durability and structural integrity of sheet metal constructions. Extreme temperatures can lead to thermal expansion and contraction, affecting the metal’s stability over time. Moreover, exposure to corrosive elements in challenging weather conditions can accelerate the deterioration of sheet metal, requiring robust protective measures.

Surviving extreme temperatures is a critical aspect of sheet metal resilience in construction. Materials need to withstand scorching heat, icy cold, and everything in between. Choosing the right alloys and coatings becomes paramount in ensuring that sheet metal can endure these temperature extremes without compromising its structural integrity. Thermal conductivity and resistance are key considerations in selecting materials, as they play a vital role in mitigating the adverse effects of temperature fluctuations.

Rust and Corrosion

Rust is a persistent challenge for sheet metal in extreme environments. Dealing with rust involves a straightforward approach: prevention and maintenance. Regularly inspect metal surfaces for signs of rust, focusing on vulnerable areas like joints and corners. When rust is detected, address it promptly using a wire brush or sandpaper to remove the corrosion, followed by applying a rust converter and protective coating. Prevention is key; keep metal surfaces clean, dry, and apply a rust-resistant primer and paint.

To protect sheet metal in extreme environments, strategic measures are crucial. Utilize corrosion-resistant alloys for construction, providing a natural defense against rust. Galvanization, involving coating metal with a layer of zinc, acts as a formidable barrier against corrosion. Regularly inspect and replace damaged coatings to maintain effectiveness. Consider applying sacrificial anodes, made of metals more prone to corrosion, to divert rust away from critical components. In extreme environments, a proactive approach to rust management and robust protective strategies ensure the longevity and performance of sheet metal structures.

Structural Challenges

Sheet metal construction grapples with formidable structural challenges, notably bending and bowing issues alongside the critical task of upholding integrity in demanding conditions. Precision in steel fabrication is super important to protect from deformation, which is a persistent concern. The stakes elevate in extreme environments, stress-testing the structural foundation to its limits. Sustaining stability amidst external pressures, weather fluctuations, and environmental stresses forms an ongoing battle. This demands not only resilient materials but also astute design and execution. Navigating these challenges requires a meticulous approach, where each bend and joint serves as a vital component in the puzzle of enduring structural integrity.

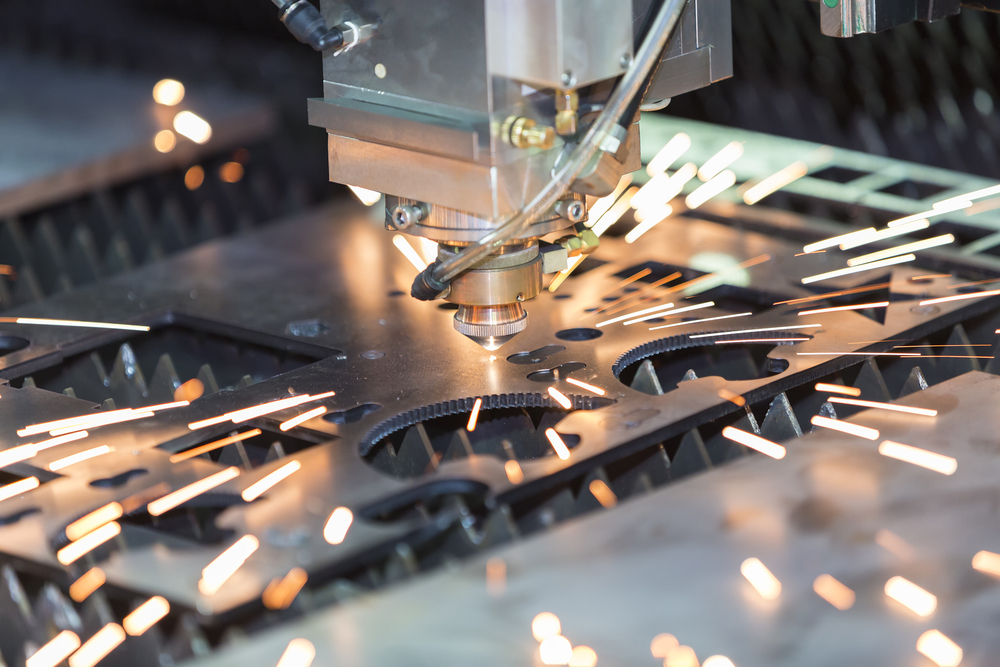

Technology Solutions

Addressing challenges in sheet metal construction within extreme environments requires robust technological solutions. A critical obstacle is corrosion, a persistent threat to structural integrity. Utilizing advanced technologies tailored to combat corrosion is vital. These solutions, spanning protective coatings to corrosion-resistant alloys, serve as formidable shields against corrosive forces prevalent in extreme conditions.

Equally crucial is the strategic selection of materials. Carefully evaluating properties such as corrosion resistance and durability is imperative. By integrating technology with material science, construction professionals bolster sheet metal structures, enhancing their resilience against harsh environmental conditions. This synergistic approach to technological innovation and material expertise is essential for overcoming the challenges presented by extreme environments in sheet metal construction.

Conclusion

As discussed, sheet metal plays a significant role in construction due to its strength and adaptability. This post has explored some of the practical strategies for addressing the challenges that come up when working with it, emphasizing the importance of thoughtful material selection and precise engineering.

From proactive rust prevention to strategic design considerations, the construction industry employs a calculated approach.The successful integration of technology and material expertise emerges as the key to thriving in challenging construction landscapes.