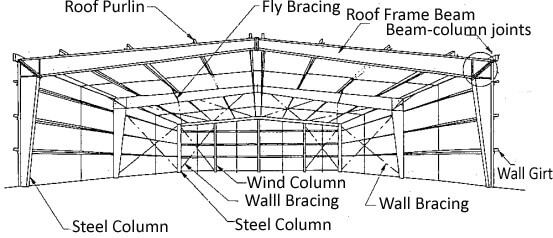

Steel Structure detail shows the portal frame structure’s specification, which most commonly uses building structure for Warehouse, Workshop, Garage, and Aircraft Hangar.

The steel structure is a structure mainly made of steel, and it is one of the main types of building structures. The characteristics of steel are high strength, lightweight, excellent overall rigidity, and strong deformability. So it is especially suitable for large-span, super-high and super-heavy buildings. The steel structure is a steel beam, steel column, steel truss, and other components made of section steel and steel plate, and welds, bolts, or rivets connect each component.

Steel Structure Detail for Port Frame Structure:

The lightweight portal frame is a single-story steel building, which beams and columns rigidly connected. It has the advantages of simple structure, lightweight, and all the factory components, easy for assembling on site.

The portal frame steel structure is widely used for industrial, commercial, and agricultural buildings, such as steel warehouses, workshop buildings, Storage, Poultry building, and aircraft hangar.

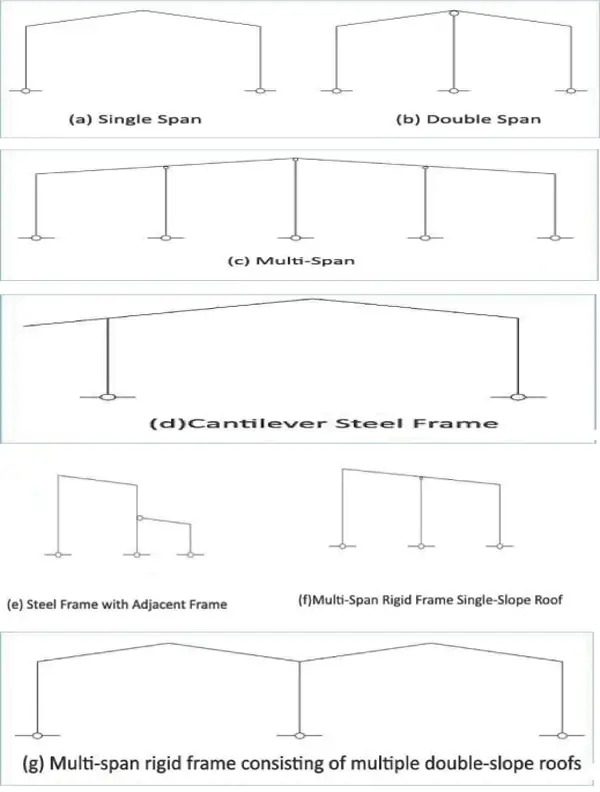

The portal frame can divide into single-span (Figure a), double-span (Figure b), multi-span (Figure c) cantilever steel frame (Figure d) ), and steel frame with the adjacent frame (Figure e).

In the multi-span rigid frame, the connection between the column and the roof beam is generally hinged, and the multi-span rigid frame single-slope roof (Figure f).

The multi-span rigid frame consisting of multiple double-slope roofs can also be used (Figure g). The beam-column cross-section can be equal or variable, and the base of columns hinged or rigid connected.

Length and Width of Steel Building :

Generally speaking, according to the principle that the long side is greater than the width, the amount of steel used in the rigid frame can be reduced. The support between the columns can be reduced, thereby reducing the amount of metal used in the support system.

Example 1: The size of the building is 60x50m, 60m should use as the length and 50m as the width, that is: 60 (L) x50 (W), not 50 (L) x60 (W).

Column Distance

The most economical column distance under standard load is 7.5-9m. When it exceeds 9m, the steel consumption of roof purlin and wall girt will increase too much, and the overall cost is not economical. The standard load here refers to 0.3KN / m2 for live roof load and 0.5KN / m2 for essential wind pressure. When the loading is more significant, the economic column distance should reduce accordingly. As for a workshop building with more than 10 tons crane, the financial column spacing should be 6-7m.

When arranging column spacing, if unequal column spacing is required, try to arrange the end span column spacing to be smaller than the center span. It is because the wind load at the end span is larger than the center span. Besides, when using a continuous purlin design, The deflection of the end span and the mid-span bend is always more significant than other spans. Using smaller end spans can make roof purlin design more convenient and economical.

Example 1: Building length = 70mEconomical column distance is available: 1 @ 7 + 7 @ 8 + 1 @ 7 or 1 @ 8 + 6 @ 9 + 1 @ 8

Example 2: Building length = 130m, with a 10-ton crane

Economical column distance is preferable: 1 @ 5.5 + 17 @ 7 + 1 @ 5.5 or 20 @ 6.5

Steel Structure Detail-Roof slope

The roof slope decides according to comprehensive factors include the structure of the roof, the length of the drainage slope, and the height of the columns. Generally, it is 1/10 ~ 1/30. Studies have shown that different roof slopes significantly impact the amount of steel used in rigid steel frames. The following results from the calculation and analysis of the steel consumption under different roof slopes with a single span of 42m and an eave height of 6m.

When the roof slope is 0.5: 10, the frame’s weight is 3682 Kg when the roof slope is 1: 10, the amount of a frame structure is 3466 Kg. When the roof slope is 1.5: 10, the weight of a frame is 3328 Kg. When the roof slope is 2: 10, the amount of a frame structure is 3240 Kg.

So for a single-span rigid frame, a better way to reduce the rigid frame’s weight is to increase the roof slope. The larger the hill, the less steel used. However, the situation is different for a multi-span frame. A large slope will increase the amount of metal used in the frame. It is because a large hill will increase the length of the inner column.

When the building’s span is large, increasing the incline can reduce the deflection of the roof steel beam. Through research and calculation, the more economical slope is: multi-span buildings: 1:20 single span, span less than 45 m: 0.5: 10 single span, span less than 60m: 1.5: 10 single span, more than 60 m span : 2: 10

The roof slope is also related to whether the building has a parapet wall, and the large hill will lead to an increase in the cost of the parapet wall.

Steel Structure detail-Eave Height

The eave height has a significant impact on the cost, which mainly manifested in the following aspects:

Increasing the prefab steel building‘s height will cause the wall cladding to grow, the wall girt to grow, and the amount of steel used for columns will be more.

If the steel column has no lateral bracing (such as the center column or the side column without a brace), the influence of the eave height on the frame weight will be more prominent; An increase in eave height will result in an increase in wind load on the frame. If the height/building width is> 0.8, to control the lateral displacement, sometimes it is necessary to change the column foot from hinged to rigid.

The following factors determine the height:The height requirements at the eave;

When there is a mezzanine structure, the net height of the mezzanine and the height of the mezzanine beam;

Height of crane beam and crane hook when the crane is available.

The Characteristics of Steel Structure:

- The steel is tough, good plasticity, uniform material.

- The steel structure is heat-resistant and not fire-resistant.

- The steel structure has weak corrosion resistance.

- The high degree of mechanization of steel structure manufacturing and installation.

- High strength and seismic resistance