Rotary lobe pumps are essential in various industries for transferring liquids, especially those that are viscous or contain solids. Their design and functionality make them versatile and reliable in handling a wide range of fluids.

How Rotary Lobe Pumps Work?

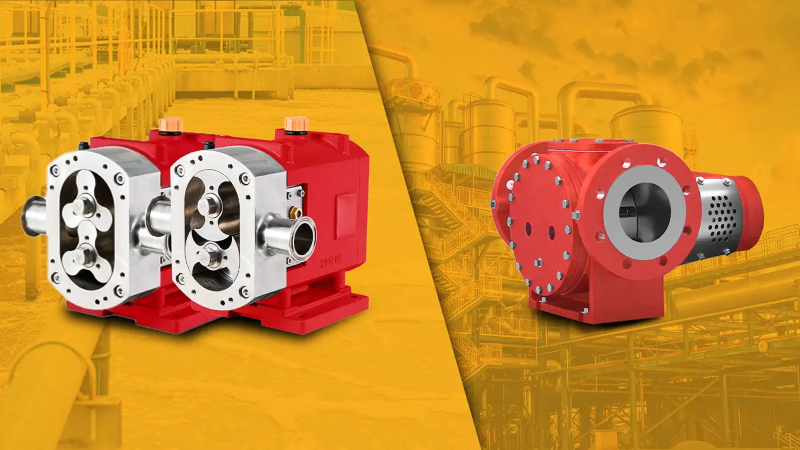

Rotary lobe pumps are a type of positive displacement pump characterized by their unique internal structure. The core components of a rotary lobe pump are the lobes, which are designed to rotate inside a cavity. As the lobes turn, they create a vacuum that draws the fluid into the pump chamber. This rotation traps the fluid between the lobes and the chamber wall, moving it from the inlet to the outlet.

The rotating lobes move in a synchronized manner to avoid interference and maintain a continuous flow of fluid. This mechanism ensures that the pump can handle varying viscosities and is effective in both low and high-pressure applications. The gentle action of the lobes also minimizes shear forces, making the pump suitable for delicate fluids.

Types of Rotary Lobe Pumps

Rotary lobe pumps come in several configurations, each designed to meet specific operational needs. The most common types include:

- Single Lobe Pumps: These pumps feature a single lobe that rotates inside the pump chamber. They are typically used for applications requiring lower flow rates and are suitable for less demanding environments.

- Double Lobe Pumps: Equipped with two lobes, these pumps provide a higher flow rate compared to single lobe pumps. They are ideal for moderate to high-viscosity fluids and offer a more stable flow.

- Multi-Lobe Pumps: These pumps have three or more lobes and are designed for high-flow applications. Multi-lobe pumps are beneficial in industries where large volumes of fluid need to be transferred efficiently and reliably.

Applications of Rotary Lobe Pumps

Rotary lobe pumps are widely used across various industries due to their adaptability and efficiency. Their applications include:

- Food and Beverage Industry: In this sector, the pumps handle everything from thick sauces to delicate dairy products. Their ability to process viscous and shear-sensitive fluids makes them ideal for maintaining product quality.

- Pharmaceutical Industry: Precision and cleanliness are crucial in pharmaceutical manufacturing. Rotary lobe pumps are used to transfer ingredients and formulations without contamination, adhering to stringent hygiene standards.

- Chemical Processing: Rotary lobe pumps are employed to handle aggressive chemicals and slurries. Their robust construction and resistance to chemical damage ensure reliable performance in harsh environments.

- Other Industrial Uses: Beyond these industries, rotary lobe pumps are utilized in applications ranging from wastewater treatment to cosmetic production, demonstrating their versatility across different sectors.

Advantages of Rotary Lobe Pumps

The benefits of rotary lobe pumps extend beyond their operational efficiency. Some of the key advantages include:

- Precision Flow Control: The design of the pumps allows for accurate flow measurement, making them ideal for applications where precise fluid transfer is essential.

- Handling High-Viscosity Fluids: The pumps excel in managing thick or viscous fluids that might be challenging for other pump types. This capability is particularly useful in industries like food processing and chemical manufacturing.

- Gentle Handling of Delicate Materials: The pump’s mechanism minimizes shear forces on the fluid, preserving the integrity of delicate or shear-sensitive materials.

- Ease of Maintenance: The pumps are designed for straightforward maintenance. Their modular construction allows for easy disassembly and cleaning, ensuring minimal downtime and extended service life.

Maintenance and Troubleshooting

To ensure optimal performance, the pumps require regular maintenance and occasional troubleshooting. Routine maintenance includes checking the condition of the lobes and seals, ensuring proper lubrication, and monitoring for any signs of wear or damage. Regular cleaning and inspection help prevent issues such as clogging or leakage.

Common troubleshooting concerns may include issues with flow rate, unusual noises, or leaks. These problems can often be addressed by inspecting the pump’s components, adjusting the operating parameters, or replacing worn parts. Maintaining a consistent maintenance schedule is crucial for avoiding significant operational disruptions and extending the pump’s lifespan.

Conclusion

Rotary lobe pumps are a reliable and versatile choice for various industrial applications. Their unique design and operational advantages make them suitable for handling a wide range of fluids, from delicate and shear-sensitive materials to high-viscosity substances. Understanding their operation, types, applications, and maintenance requirements can help in selecting the right pump and ensuring its long-term efficiency.

For more detailed information on rotary lobe pumps, including specific product recommendations and technical support, consulting with industry experts and manufacturers can provide valuable insights tailored to your needs.