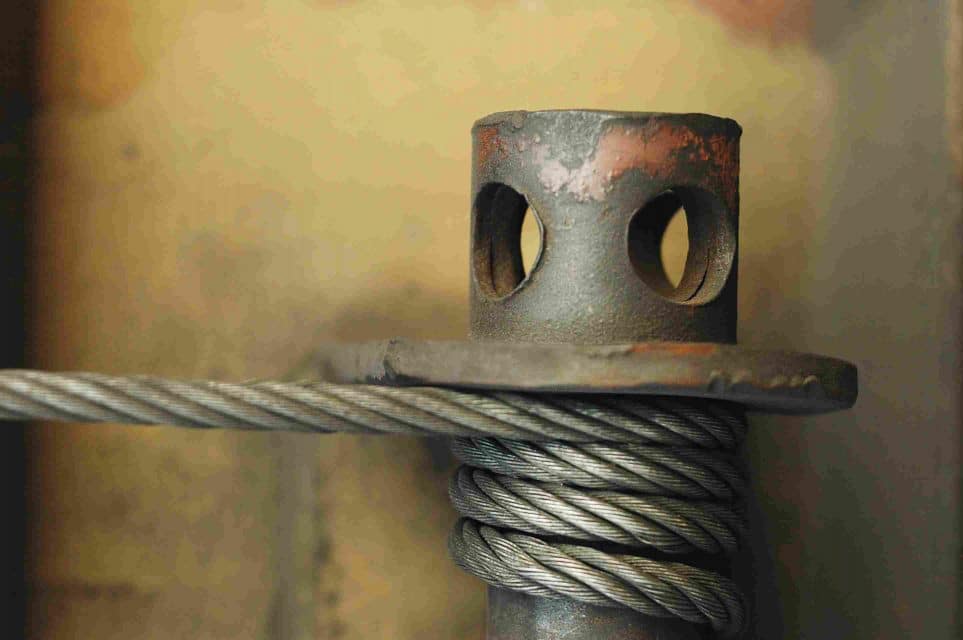

Wire Ropes for Rigging are a critical piece of industrial hardware equipment for rigging and lifting applications. On a basic level, they are used to attach cranes to extremely heavy equipment or items that need to be moved from one place to another.

Over time, these tasks will break down the wire ropes, causing them to lose strength or even break. This can be extremely dangerous – and unfortunately, about 11% of work fatalities on construction sites are related to objects falling or striking a person due to equipment malfunctions.

Extending the life of your wire ropes can help to reduce this risk. It will also help to lower costs, as wire rope can be quite expensive to purchase and time-consuming to remove and re-install. Here are five simple tips that construction site managers can use to ensure that the wire ropes in rigging equipment are long-lasting.

1. Start with Top Quality Wire Ropes

First and foremost, it is important to purchase top-quality wire ropes which are highly rated for strength and durability. It is also important that you use the right material and finish for your application, as well as the right weight range.

If you are constantly pushing the weight limits to the maximum on the ropes, it can cause it to stretch more and break down faster. Instead, it is best to go up one weight rating with a stronger wire rope to prevent this from occurring.

There are two general types of wire ropes used for rigging: galvanized and stainless steel.

Galvanized wire rope is coated in zinc to provide additional protection from elements like rain, rust, as well as scratches and wear. Stainless steel wire rope is stronger than galvanized, but it is also more expensive.

There are several other factors you must take into consideration when purchasing wire rope, such as:

Rope grade (IPS, EIPS, EEIPS)

Type of core (fiber, independent wire rope, wire standard)

Diameter and number of strands

Construction (rotation resistant, compacted strand, swaged wire, plastic coated)

Each type and style of wire rope is designed for specific purposes and weights. Ultimately, it is best to order wire rope through a trustworthy rigging equipment supplier. They will be able to explain which type of rope will be best for the job at hand.

2. Know What Wears Down Wire Ropes

Next, you should be aware of the conditions that cause wire ropes to break down. The ropes which are more “at-risk” of wear and tear should be inspected more frequently to identify any points of weakness or signs of deterioration – before it becomes a major issue.

Some of these operating characteristics include:

Speed of operation acceleration and deceleration

Rope that is used for high-speed operation is prone to more friction, which can wear down the wire strands. If the wire ropes are used for cranes or pulley systems that are operating at high speeds, it could be more vulnerable to wear.

Rope attachments

The type of attachment can also impact the wire rope’s strength. For instance, large heavy hooks can cause the attachment point to break down over time due to additional stress to this area.

Environmental conditions

Harsh weather conditions like rain, moisture, or extreme temperatures can cause the wire rope to corrode and wear down. Stainless steel is naturally rust-resistant, but constant exposure to the elements can cause damage.

3. “Break-In” New Ropes

When you first install a wire rope, run it without any load. Gradually build up the weight to allow the rope to stretch and “ease” into weight-bearing. Wire ropes will naturally start to stretch and become a bit more flexible over time. A rope will typically stretch between .25% to 1% of the entire length.

Placing an extremely heavyweight on the rope from the jump can cause it to stretch too far too quickly, which could compromise the strength of the wire strands.

4. Remove or Repair Wear Points

If a wire rope does start to wear down or fray, there is no need to get rid of it entirely. You can remove these worn-down parts and create a shorter rope. To prolong the rope’s life, cut off sections of broken wires and reverse the ends to prevent the rope from unraveling at its new endpoints.

You should also repair small areas that are starting to show signs of wear by wrapping it with another wire to create a seized end. This wire may also be fused and melted to prevent it from unraveling.

Finally, reverse the ends of the wire rope from time to time to promote more even wear. When one piece of the rope is receiving all of the wear, friction, or dragging, it will break down quicker.

5. Clean and Lubricate Regularly

Finally, it is important that you clean wire ropes regularly to remove buildup that could scratch the wire rope. This can accumulate from dust and dirt, which is quite common on most construction sites and areas where rigging equipment is used.

It is also important to regularly lubricate the machinery to create a protective layer which reduces friction and keeps the wire more pliable and strong. You can apply lubricant by dripping it on, spraying it, or brushing it. All of these methods are equally sufficient, so long as the entire circumference of the rope is evenly covered.

Conclusion

Wire rope is an expensive but an essential piece of equipment in rigging – and you need to be taking extra care to promote long-lasting durability. Frequent use, exposure to the elements, as well as improper cleaning and maintenance can shorten the life of wire ropes. Neglecting proper care can cause them to break down, which could result in costly and dangerous problems down the road.

By using these simple tips, construction managers can ensure that the wire ropes used in rigging equipment are not only long-lasting but also safe and secure.

It made sense when you said that wire ropes should be cleaned and lubricated often. My neighbor is looking for wire ropes and chain slings to buy. This info should help him care for the rigging equipment properly.