The Innovative Construction, where every project is a masterpiece waiting to be crafted, there exists a powerful ally that promises to transform your architectural dreams into tangible reality: CNC Machining. This technological marvel has unleashed a wave of possibilities, rewriting the rules of construction with its precision, speed, and design flexibility.

Are you tired of limitations? Do you long to push the boundaries of what’s possible in construction? CNC Machining is your answer. It’s more than a tool; it’s a revolution that grants architects, engineers, and builders the creative freedom they’ve been yearning for. The fusion of digital precision and the physical world is now at your fingertips, ready to sculpt, carve, and shape your imagination into structures that defy convention.

If you’re ready to embark on a journey where innovation knows no bounds, join us as we explore how Online CNC Machining becomes the cornerstone of Innovative Construction by unlocking the limitless potential of design flexibility. Let’s turn your architectural dreams into breathtaking realities.

What is CNC Machining?

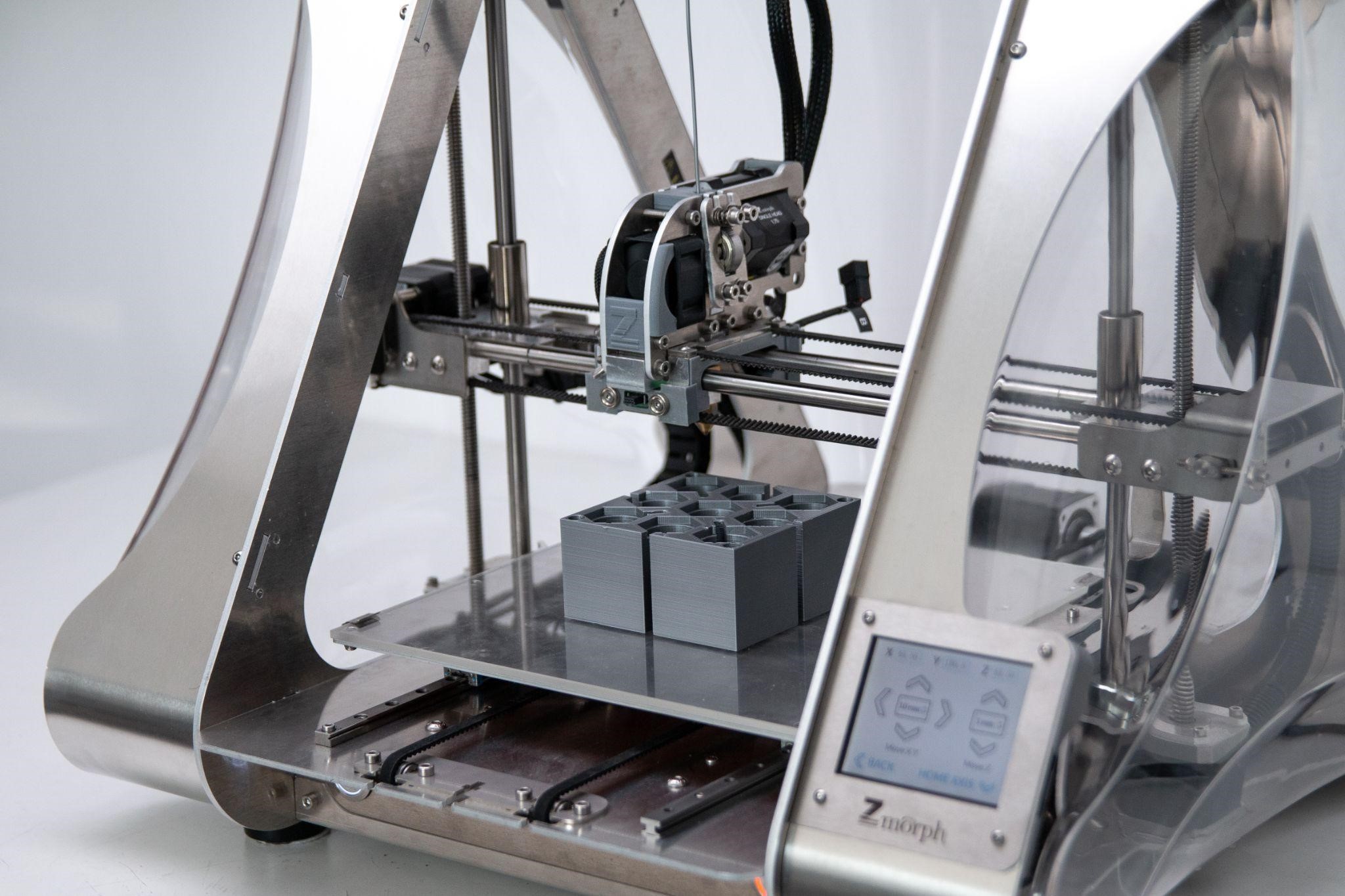

CNC machining stands as the vanguard of precision engineering in the modern world. CNC, or Computer Numerical Control, refers to a cutting-edge manufacturing process that marries computational power with mechanical finesse. It’s the art of transforming raw materials into intricate components with unparalleled accuracy.

Advantages of Online CNC Machining

Online CNC machining is a game-changer in modern manufacturing and construction, offering three key advantages:

Precision and Accuracy

CNC machining achieves micrometer-level precision consistently, making it ideal for intricate designs and complex components across various industries.

Speed and Efficiency

CNC machining operates swiftly, reducing lead times and production costs. It streamlines prototyping and large-scale production, boosting project progress.

Customization Options

CNC machining excels at customization. It crafts bespoke components with intricate designs and allows for easy design tweaks, meeting diverse industry needs efficiently.

Innovation in Construction

In an era of technological advancement, the construction industry is experiencing a profound transformation driven by the integration of cutting-edge techniques like CNC machining. This marriage of precision engineering and construction has led to remarkable advancements, reshaping how we conceive and erect structures.

The inclusion of CNC machining has revolutionized the fabrication of intricate components, enabling architects and engineers to push the boundaries of design. From custom architectural elements to precision-engineered parts, this technology empowers construction with unprecedented accuracy and versatility.

Online CNC Machining in Construction

The construction sector has witnessed a transformative shift with the integration of precision engineering and architectural expertise, thanks to the implementation of online CNC machining. By harnessing the potential of CNC (Computer Numerical Control) machining, intricate components and architectural elements are crafted with unmatched precision.

Computer-guided machinery takes the helm in this process, turning raw materials into exact designs, ensuring each shape aligns perfectly with its blueprint. Beyond crafting custom components, online CNC machining also speeds up prototyping and boosts the efficiency of detailed architectural projects.

Applications of CNC Machining in Construction:

Prototyping and Rapid Iteration

CNC machining allows quick transformation of digital designs into precise physical prototypes, facilitating early issue identification and resolution.

Custom Components and Parts

It excels at crafting tailored components, ensuring seamless integration into construction projects.

Complex Architectural Elements

CNC machining empowers architects to bring intricate and innovative designs to life, redefining modern architecture.

Cost-Effective Solutions

Efficiency and reduced material wastage translate into significant cost savings over construction timelines.

Enhancing Safety

Automated processes minimize human error, enhancing safety for construction workers and projects.

Sustainability and Online CNC Machining

Sustainability and Online CNC machining converge at the cutting edge of environmentally conscious construction. Sustainability entails responsible practices that minimize ecological impact. Online CNC machining aligns seamlessly with this ethos by enabling precise, eco-friendly material processing. It reduces waste through precision engineering and supports green building with energy-efficient component fabrication. This synergy fosters construction that not only erects structures but also safeguards our planet for future generations, making sustainability and Online CNC machining integral to a greener future

Challenges and Considerations in the Realm of CNC Machining

As industries embrace the cutting-edge technology of CNC (Computer Numerical Control) machining, they encounter a host of opportunities and complexities. In this article, we will delve into the intricacies of implementing CNC machining and the challenges and considerations that come with it.

Potential Challenges in Implementing CNC Machining

The adoption of CNC machining is not without its hurdles. Firstly, the transition from traditional manufacturing methods to CNC-controlled processes can be daunting. It requires the acquisition of CNC machinery and skilled technicians who are proficient in both operating the machines and programming them.

Cost Considerations

The initial investment in CNC equipment, encompassing the machinery itself and the required software, can be substantial. These costs, however, should be viewed as investments rather than expenses. CNC machining often leads to long-term savings by reducing material wastage, enhancing precision, and increasing production efficiency.

Training and Skill Development

CNC machining demands a skilled workforce proficient in various aspects of the technology. Employees must be trained in CNC programming, machine operation, and maintenance to ensure seamless operations.

Conclusion

The fusion of technology and innovation shines brightly. Online CNC Machining is the beacon of this union, offering a future defined by precision and efficiency. Explored in the article “How Online CNC Machining Supports Innovative Construction,” this technology is a transformative forcef rom precise engineering to crafting architectural wonders, Online CNC Machining redefines what’s possible in construction. It empowers architects, engineers, and builders to bring their grandest visions to life. Construction embraces sustainability and efficiency, Online CNC Machining remains the indispensable tool, shaping the future with its unwavering dedication to innovation, precision, and versatility.