Precision Engineering is not just influential; it’s revolutionary. This meticulous discipline introduces a suite of features that are transforming everyday gadgets into marvels of technology. The precision with which components are engineered and assembled results in devices that are sleeker, more robust, and more integrated than ever before. The advantages extend beyond mere aesthetics, impacting performance and longevity. Devices crafted with such exactitude offer superior efficiency and durability, ensuring they outlast and outperform their predecessors.

The benefits to consumers are manifold. From smartphones that pack cutting-edge technology into slim profiles, to wearables that monitor health metrics with astonishing accuracy, Precision Engineering enhances not only the functionality but also the environmental adaptability of these devices. As consumers, we experience a seamless integration of technology into our daily lives, marked by a noticeable elevation in device reliability and user experience. Discover how Precision Engineering is not just shaping but spearheading advancements in Consumer Electronics, making it an essential component of technological progress in the modern world.

What is Precision Engineering?

Precision engineering is a discipline of engineering that emphasizes the design and production of highly accurate components. It requires stringent adherence to exact specifications, ensuring every part meets meticulous standards with minimal error tolerance. This approach is crucial in industries where high performance and reliability are non-negotiable.

Technologies in Precision Engineering for Consumer Electronics

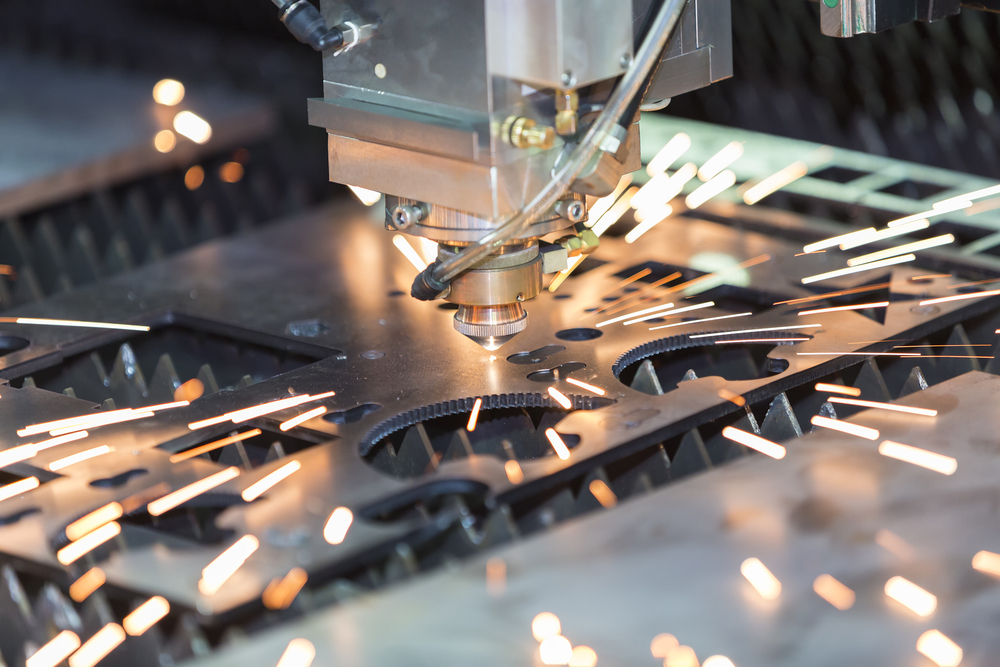

Sheet Metal Fabrication

Sheet Metal Fabrication is a vital process in precision engineering used to create intricate parts and components for various industries, including consumer electronics. It involves cutting, bending, and shaping sheet metal to meet specific design requirements. Utilizing advanced techniques such as laser cutting and CNC punching, sheet metal fabrication ensures high precision and quality in the production of electronic enclosures, brackets, and other components. With its versatility and efficiency, sheet metal fabrication plays a crucial role in the manufacturing of modern consumer electronic devices.

Injection Molding

Injection molding is a manufacturing process used in precision engineering to create intricate components for various industries, including consumer electronics. This method involves injecting molten material, often plastic, into a mold cavity under high pressure. The material then cools and solidifies, taking the shape of the mold. The process enables the production of complex shapes with high precision and consistency, making it ideal for manufacturing electronic components like casings, connectors, and enclosures. Injection molding offers cost-effective production and allows for rapid prototyping and mass production of components used in modern consumer electronics devices.

CNC Machining

Computer Numerical Control (CNC) machining stands out in precision engineering with its ability to produce precise parts with excellent repeatability. It is pivotal in creating intricate components found in consumer electronics, where exact dimensions are crucial for seamless assembly.

Laser Cutting and Etching

Laser cutting and etching provide high precision in shaping materials, essential for detailed designs and miniaturized electronics. These techniques allow for the creation of intricate patterns and features on metals, plastics, and other materials, contributing significantly to both functionality and aesthetic appeal.

3D Printing

3D printing has revolutionized prototype development, enabling rapid testing and refinement of designs. This technology allows for cost-effective customization of parts, supporting innovation in consumer electronics by making it feasible to explore complex product designs without extensive costs.

Advantages of Precision Engineering

Enhancing Product Quality

Precision engineering stands at the forefront of quality assurance in manufacturing. By integrating advanced technologies and meticulous processes, this discipline ensures that every product component is produced with exact precision. This not only minimizes the occurrence of defects but also enhances the product’s overall functionality. High-precision tools and techniques, such as computer numerical control (CNC) machines and laser scanning, provide unmatched accuracy that is evident in the final product’s superior performance and reliability. This rigorous attention to detail guarantees that products not only meet but often exceed customer expectations.

Increasing Manufacturing Efficiency

Efficiency in manufacturing is pivotal for meeting production deadlines and managing costs. Precision engineering contributes significantly to streamlining production processes, thereby increasing throughput. Automation and precision technologies enable faster production cycles while maintaining high quality. For instance, CNC machining processes are highly repeatable, which reduces the time spent on quality control and adjustments during mass production. This consistent repeatability also reduces downtime and accelerates delivery to market, providing a competitive edge in fast-paced industries.

Reducing Material Waste

In today’s eco-conscious world, reducing material waste is not only a financial concern but an environmental imperative. Precision engineering plays a critical role in material conservation through its ability to precisely cut and shape materials with minimal excess. Techniques such as additive manufacturing, like 3D printing, build components layer by layer, which significantly decreases the amount of wasted material compared to traditional subtractive methods. This efficient use of materials not only lowers costs but also aligns with sustainable practices, reducing the industry’s carbon footprint.

Improving Safety Standards

The meticulous nature of precision engineering also enhances the safety of manufactured products. In industries where safety is paramount, such as aerospace and automotive, precision engineering ensures that all parts meet strict regulatory standards and operate reliably under extreme conditions. The precise fabrication of automotive safety components, such as brake systems and airbag mechanisms, directly affects their performance in critical situations. By maintaining high accuracy in these components, precision engineering reduces the risk of malfunctions and increases the overall safety of end-users.

Cost-Effectiveness Over Time

It may require a significant initial investment in terms of sophisticated equipment and skilled labor, but the long-term financial benefits are substantial. High-quality, durable products result in reduced maintenance costs, fewer recalls, and less need for replacements over time. Moreover, the efficiency and material conservation aspects of precision engineering contribute to a decrease in production costs. Over time, these factors lead to improved profitability and a stronger return on investment, making precision engineering a wise choice for sustainable business practices.

Impact of Precision Engineering on Consumer Electronics

Quality and Reliability

Precision engineering directly contributes to the enhanced quality and reliability of consumer electronics. Devices are increasingly expected to perform flawlessly under various conditions, and precision engineering ensures that each component can meet these high expectations consistently.

Miniaturization

One of the most notable impacts of precision engineering is the miniaturization of electronic devices. Advanced manufacturing techniques have enabled the production of smaller, more powerful devices that are more convenient and portable without sacrificing performance.

Innovation in Product Features

Precision engineering fosters innovation in product features, allowing manufacturers to integrate sophisticated functionalities into consumer electronics. From waterproof smartphones to wearables with advanced sensors, precision engineering is at the heart of many of the groundbreaking features that enhance user experience.

Conclusion

The influence of precision engineering on consumer electronics is profound and far-reaching. By driving quality, reliability, and innovation, this key discipline not only shapes current technology trends but also paves the way for future advancements. As consumer expectations evolve, the role of precision engineering in meeting these demands will undoubtedly continue to grow, reinforcing its essential status in the tech world.