Water jet cutting is a fast and versatile cutting method that employs a high-pressure water jet to cut through a variety of materials. It is widely used in a variety of industries, including construction engineering. Water jet cutting has a wide range of applications in construction engineering, from hard material cutting to intricate design to demolition and remodelling. This article will look at the different applications of water jet cutting in construction engineering, as well as its benefits, challenges, and future potential.

Water Jet Applications in Civil Engineering

Cutting Hard Materials

Cutting through hard materials is one of the most common applications of a water jet cutting machine in construction engineering. Water jets with high pressure can easily cut through materials that would be difficult or impossible to cut with other methods. Water jet cutting can cut through the following materials:

- Water jet cutting can easily cut through reinforced concrete, making it an excellent method for severing concrete structures.

- Stone is another hard material that water jet cutting can easily cut through. It’s a popular way to cut stone tiles and slabs for building projects.

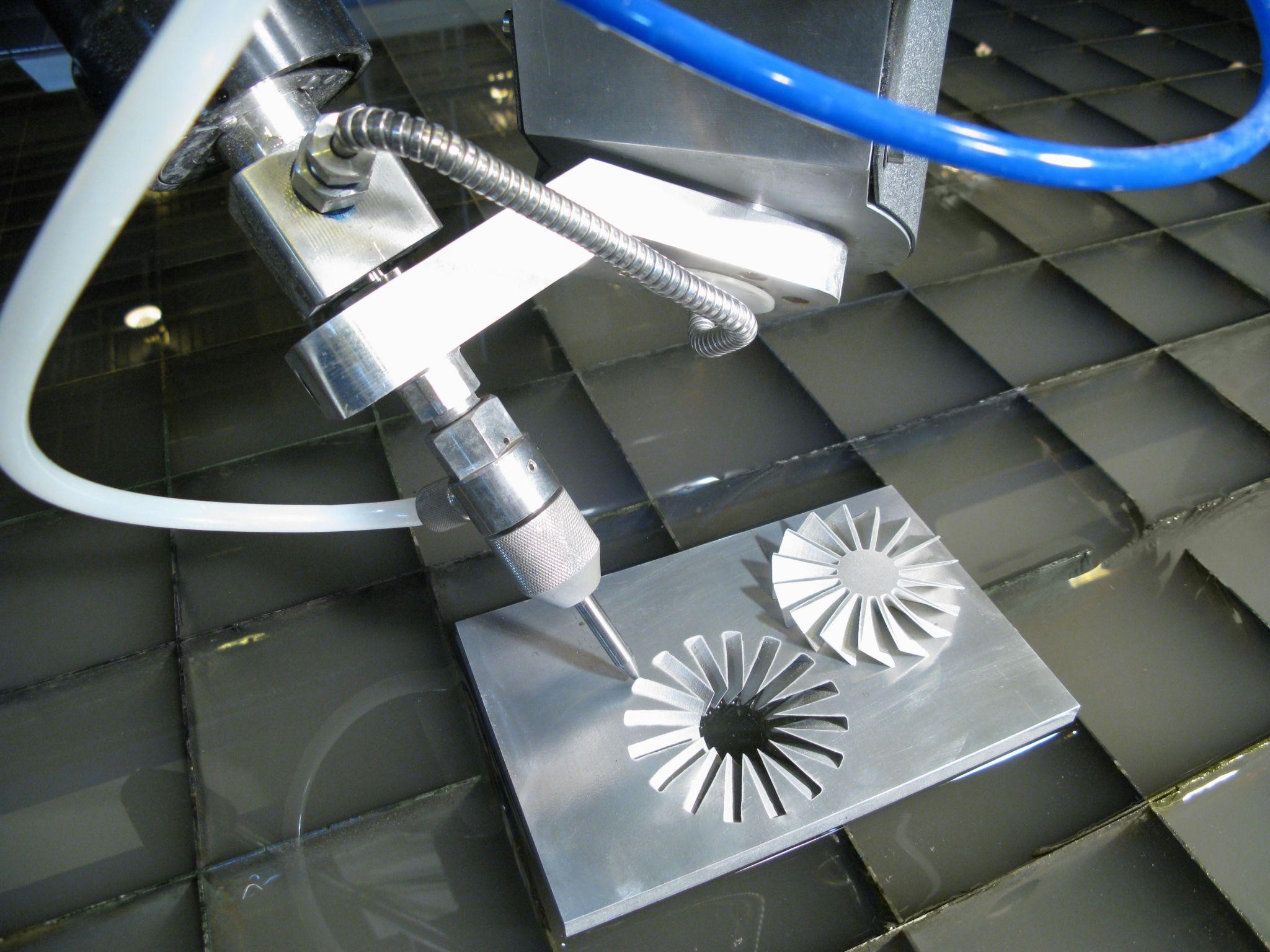

- Water jet cutting is a common method for cutting metals such as stainless steel, aluminium, and titanium. It’s frequently used to cut metal sheets and plates for building facades and other construction projects.

- Water jet cutting is also capable of cutting through glass, making it a popular method for cutting glass panels for building facades and interior design.

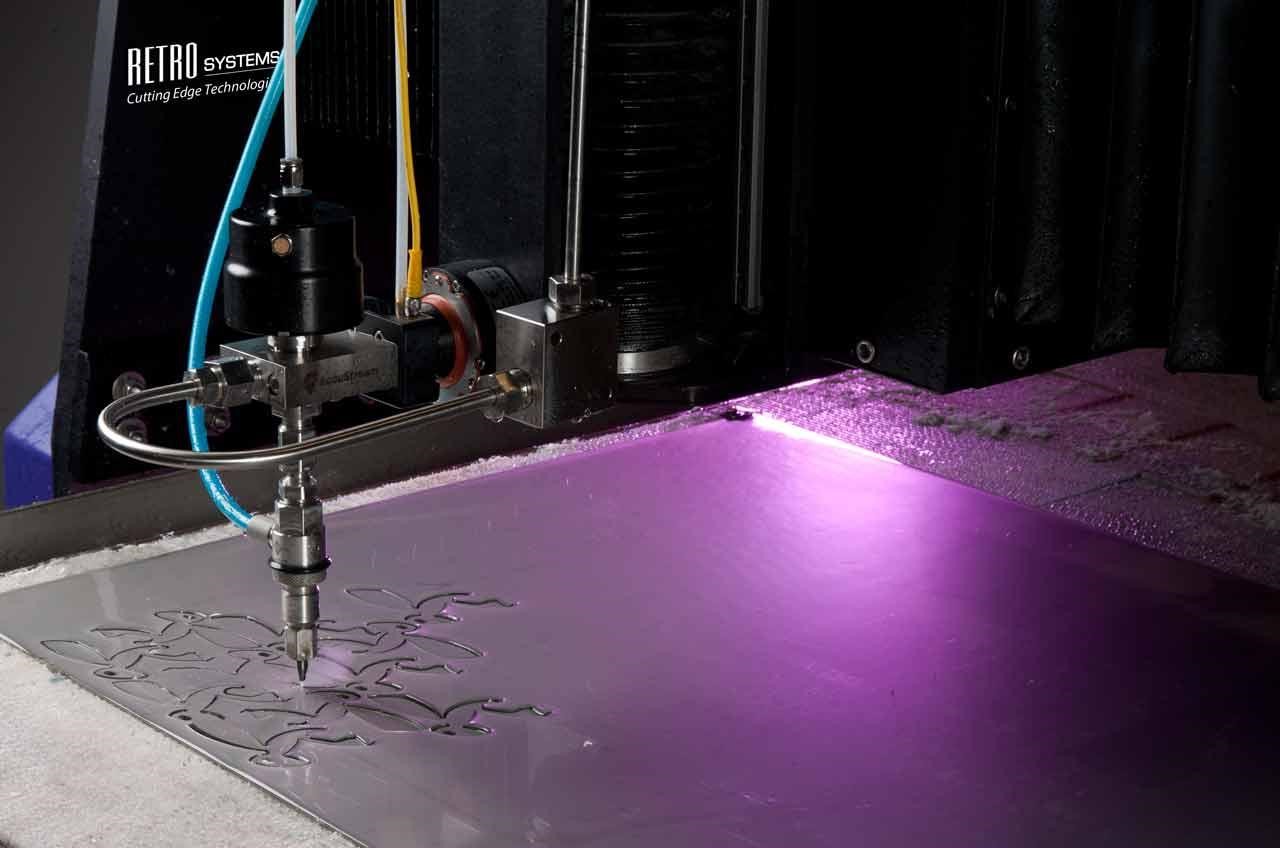

Making Complex Designs

Water jet cutting is also excellent for producing intricate designs in a wide range of materials. Because of its high precision and accuracy, it is a popular choice for tile and marble work, as well as for creating wall panels and facades. Water jet cutting can produce complex patterns and designs in materials such as marble, granite, and glass. As a result, it is a popular method for creating one-of-a-kind and custom-designed surfaces for construction projects.

Remodelling and Demolition

Water jet cutting is also a popular method in construction engineering for demolition and remodelling projects. It can easily cut through concrete, brick, and other building materials, making it ideal for controlled demolition and building structure removal. Water jet cutting is also useful for structural demolition because it can cut through building elements while leaving adjacent elements intact.

Water Jet Cutting Benefits in Construction Engineering

Accuracy and precision

Water jet cutting has tolerances as low as +/- 0.005 inches, making it a highly precise and accurate cutting method. It is capable of producing complex and intricate shapes with high precision and accuracy, making it ideal for construction projects requiring precise cuts and shapes.

There is no heat-affected zone.

One of the most significant advantages of water jet cutting in construction engineering is the absence of a heat-affected zone. (HAZ). This means that the material being cut has no distortion, warping, or discolouration. This is especially important when cutting materials that can become distorted or warped as a result of heat.

There is no material distortion or warping.

Water jet machining also has the advantage of not causing material distortion or warping. This means that the cutting material remains flat and smooth, with no deformations or warping.

Environmentally Friendly

Water jet cutting is an environmentally friendly cutting method because it produces no hazardous waste and emits no harmful gases. Water from the cutting process can be recycled and reused, lowering water consumption and waste.

Increased Productivity and Efficiency

With water jet cutting speeds of up to 500 inches per minute, it is a highly efficient and productive cutting method. It can quickly and accurately cut through materials, reducing cutting time and increasing productivity.

Water Jet Cutting’s Challenges in Construction Engineering

Costs of Equipment and Maintenance

The high equipment and maintenance costs are one of the main challenges of water jet cutting in construction engineering. Water jet cutting necessitates the use of specialised equipment and machinery, which can be costly to purchase and maintain. Furthermore, the high-pressure water jets can cause wear and tear on the equipment, resulting in higher maintenance costs.

Cutting Depth Limits

Another disadvantage of water jet cutting is its limited cutting depth. It is suitable for cutting through thin to medium-thick materials but not for cutting through thick materials. Other cutting methods, such as plasma cutting or laser cutting, may be more appropriate for thick materials.

Water and noise pollution

Cutting with a water jet can be a noisy process, especially when cutting through hard materials like concrete and metal. High-pressure water jets can produce noise levels that are hazardous to workers. Furthermore, water jet cutting can produce a large amount of runoff, which can lead to water pollution if not properly contained and treated.

Conclusion

Water jet cutting is a versatile and efficient cutting method that has a wide range of applications in the construction industry. It is an ideal cutting method for construction projects due to its ability to cut through hard materials, create intricate designs, and facilitate the demolition and remodelling projects. Furthermore, because of its precision and accuracy, lack of a heat-affected zone, and low environmental impact, it is a popular choice for many construction projects.

However, when using water jet cutting in construction engineering, challenges such as equipment and maintenance costs, limited cutting depth, and noise and water pollution must be considered. Water jet cutting has the potential to become an even more valuable tool in the construction industry as technology advances.