Industries and businesses around the world have completely changed since precision manufacturing arrived. Precision machining is known for holding more than 70% of the global machining market, making it highly significant in the 21st century. Technological advancements are the need of the hour. Precision manufacturing has unnumbered benefits for numerous industries around the globe. It’s the perfect use of technology to boost industries and magnify profit. As technology is evolving at a rapid rate, you witness very complex items around you and you may wonder who created them and how they were made. Well, here’s what you need to know about precision manufacturing;

Precision Manufacturing

When highly complex components are made using a design and all the specifications are on point with little tolerance, it is known as precision manufacturing. Numerous industries around the world require minimum tolerance such as the aerospace, or construction industry, you can’t risk the lives of passengers or people living in a building.

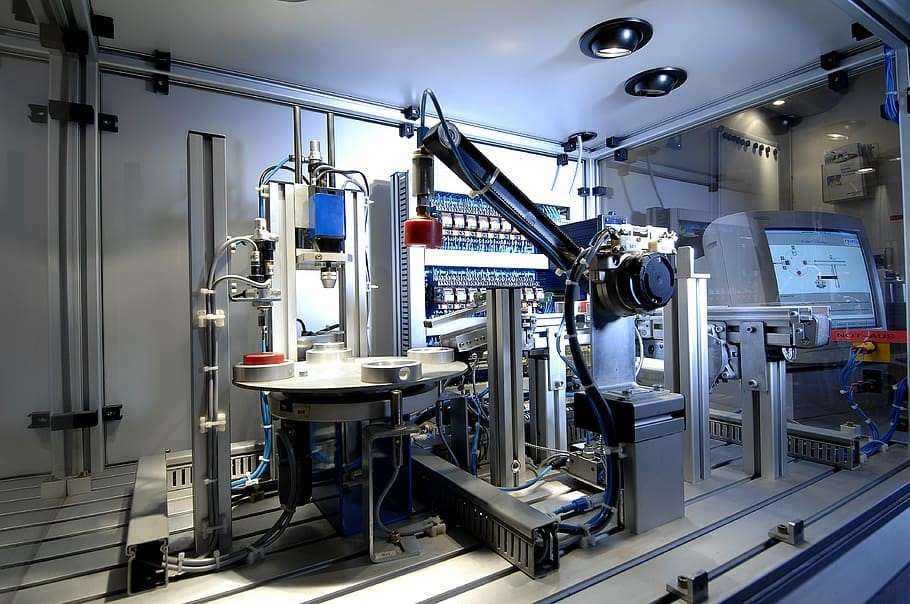

Precision machining is the use of advanced technology which is computerized to make complex geometric cuts on a material. It has an unimaginable amount of accuracy and repeatability, making it a highly reliable technology in the market. Computer numerical control (CNC) machine tools have changed the world, you can get cnc machining quotes for your industry as well. Technology such as tube cutting laser machine is highly effective to cut any type of pipe. This piece of technology is one of the most demanded in the world to help industries grow at a higher pace.

Benefits of Precision Manufacturing

Here are some of the most common benefits of precision manufacturing;

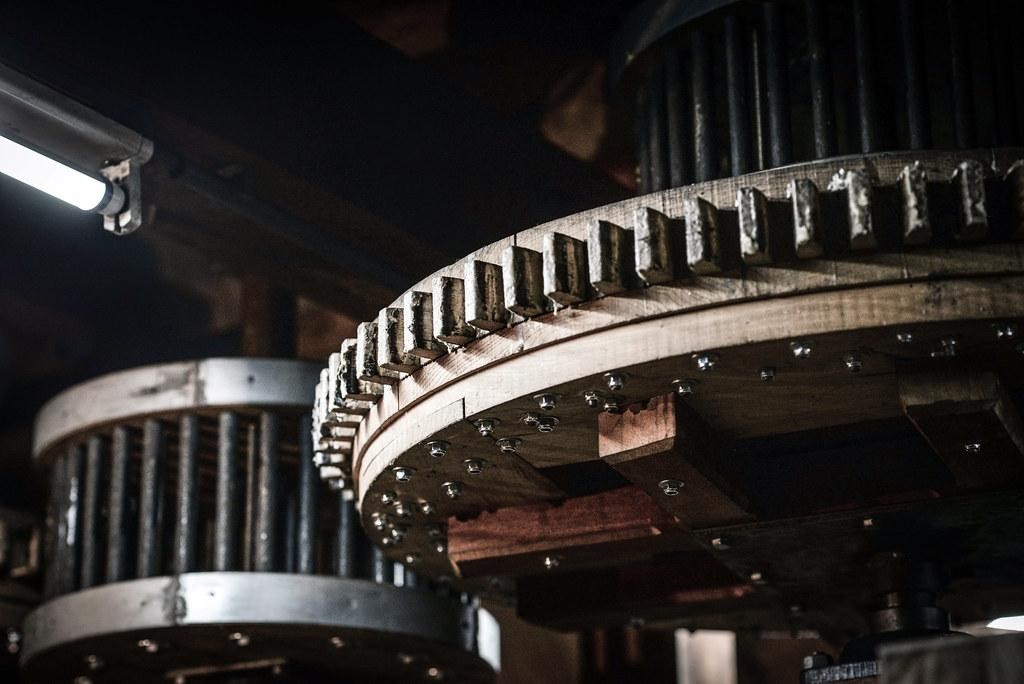

Better Tolerance

One of the major issues in the previous traditional methods of manufacturing was tolerance, the expected design was never made as finely as planned by the manufacturer. However, that is not the case with precision manufacturing. Throughout the world, the demand for complex parts is increasing. The tolerance of CNC machining tools is +/- 0.0005” on milled features and for turned parts, it is +/- 0.0001”.

Creating complex parts demands very high tolerance, look around yourself and you will see numerous metal parts that seem extremely hard to build, all thanks to precision manufacturing for creating such difficult designs with the help of CNC machining tools.

Lower Cost

It may come as a surprise, but the cost of manufacturing complicated designs with CNC machining tools is way less than conventional methods of manufacturing. One of the major expenses that are cut down in precision manufacturing is labor cost, you need minimum labor to manufacture parts. High-quality parts are made by the machine, experts only need to give the design to the software and the rest is done by the machines. It’s a one-time investment and requires lower maintenance costs too.

High Production Rate

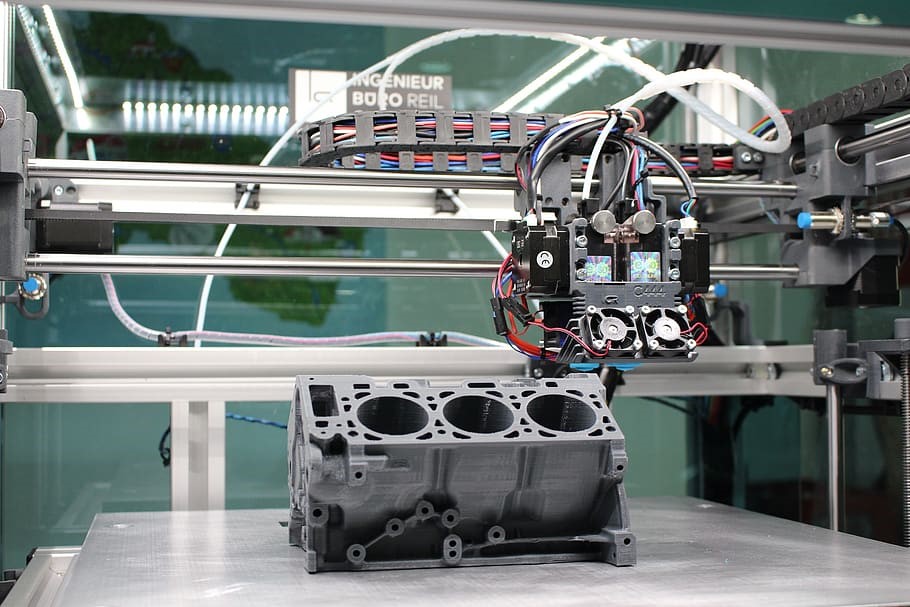

Beating your competitors with a low production rate is never an option in this part of the century. One of the fastest manufacturing methods is precision manufacturing. 3D CAD Models are responsible for controlling the machine, and custom parts are made with better speed and efficiency. You can take full use of CNC machining tools to manufacture custom parts, which can enhance the rate of production.

Versatile

Product designers face numerous challenges when it comes to product designing, as every material has its own pros and cons. For example, stainless steel has better machinability when compared with titanium, it is easier to create custom parts using stainless steel. However, when it comes to strength, titanium is much stronger than stainless steel, but it has lower machinability. Titanium has high chemical reactivity and low thermal conductivity.

If you use traditional manufacturing methods, it would be extremely hard to create parts with complex designs using materials such as titanium. Precision machining can work with a long list of materials, whether it’s copper alloy, titanium, stainless steel, aluminum, or plastic.

Easier Prototyping

One of the most important steps in a manufacturing process is prototyping, where a product is tested before introducing into the market. All the potential flaws are closely inspected to look for improvement in the product. Fast and reliable machines are used for prototyping, and investing an immense amount of money and time in testing the product will certainly lower your production rate, this is why CNC machining tools are known for making testing easier. It has rapid prototyping capabilities as you need to modify 3D CAD Models to get new designs.

Conclusion

Precision manufacturing has completely changed the way industries used to work in the past. As consumer demand has increased at a tremendous level, industries are always under pressure to manufacture at a higher speed and there’s no compromise on the quality of the goods. However, manufacturers need to have proper knowledge about all the required tools to use them at their full potential.