What will the post-pandemic world look like? The COVID-19 pandemic has affected businesses in nearly all sectors. While some industries (such as medical supplies and food delivery services) have seen increases in sales and production, others have sadly experienced dramatic drops.

According to a recent survey, 53.1% of manufacturers expect their operations will be affected by COVID-19 – and 78% anticipate that their revenue will be impacted. Globally, it is estimated that earnings for manufacturing businesses will decrease between 5% to 15% during the pandemic.

However, in some countries, these drops are expected to be far worse.

In Norway, for example, production and manufacturing companies have experienced an average of up to 25% decreases in revenue. 29% have lost half of their sales just since April of 2020.

Also read: ‘Survival Guide’ for Extended Shutdown of Commercial and Institutional Facilities

Since it is simply impossible for some industries to produce at their normal capacity due to sanitation precautions, many manufacturing companies are already preparing for their comeback post-pandemic.

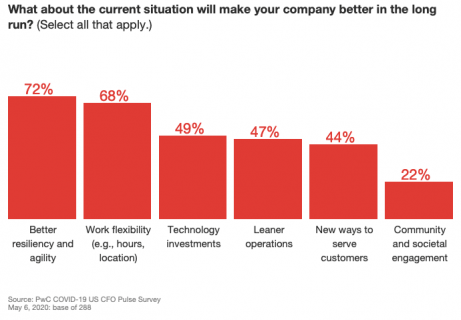

According to a survey from PwC, manufacturers are already planning their return. The majority will be searching for new ways to make the workplace safer and better, and many are also expecting to invest in new approaches.

The world is simply not going to be able to return to “normal” right after the COVID-19 pandemic passes – so here are some ways we can expect manufacturing to change in the near future.

Exploring Automation Technology

One of the most obvious transitions that manufacturers will need to make to reduce human contact is utilizing automation and robotics. It is estimated about 48% of manufacturing tasks currently rely on physical labor. By 2030, only 35% will require humans to complete.

The previously mentioned survey from PwC reported that nearly half of all manufacturers expect to invest more in technology post-pandemic. Reducing the number of people needed within a confined space can certainly help to keep employees safer. But technology like automation, collaborative robotics, and IoT (Internet of Things) are major financial investments.

Therefore, the best move for manufacturers to make in this regard is to start with sectors that will see the greatest impact. Human safety needs to be the top concern – so purchasing autonomous material movement equipment is a wise move.

For instance, automated lifting cranes can help to reduce the number of workers needed in stations and inside warehouses. This equipment uses Smart Features for enhanced safety, such as hook centering, snag prevention, and peak performance synthetic slings to reduce operational time while also providing a safer working environment.

Other types of equipment like collaborative robotics would allow workers to keep their jobs but operate in a manner that keeps them safe from contact with potentially contaminated surfaces.

Bringing More Jobs Back Home

COVID-19 has resulted in the closure of some borders to reduce the spread of the virus – and this has certainly slowed down shipping and importing for some industries. While this is certainly quite frustrating and problematic, it could have a beneficial result.

Since some manufacturers are not able to import or produce the supplies they need from overseas (particularly from countries like China), many are considering bringing those jobs back to US soil. In fact, 56% of manufacturing companies are planning to make more products in the US this year, compared to just 45% that planned to do so in the past.

Reducing the number of overseas manufacturing plants to ensure safety measures and precautions are being properly followed. While this could result in higher costs at first, it could also mean that unemployment numbers within the country could be greatly reduced once it is safe for people to return to work.

Utilizing More Virtual Communications

Most states are requesting all non-essential business operations to temporarily cease. As a result, companies are relying on technology for communication and collaboration more than ever before.

A recent survey found:

Seventy-two percent of manufacturers are communicating with customers and clients over the phone more than before.

Fifty-six percent are utilizing email marketing to better stay in touch.

But while these communication systems are certainly well and good, manufacturers will need to rely even more heavily on virtual tools to support operations post-pandemic.

Believe it or not, augmented reality could be the most effective tool for manufacturers during the pandemic – as well as after. Remote assistance solutions allow managers and supervisors to inspect production and even direct field operations remotely.

It could also be used by clients to preview products without physically coming into the plant – keeping everyone safer.

Pivot to New Post-Pandemic Opportunities

Many manufacturing plants have temporarily shifted their operations to provide essential supplies for the pandemic. For instance, Annheuser-Busch distilleries and ExxonMobil have started to produce hand sanitizer, while some automakers and textile plants are making medical grade masks for hospital workers.

While this is likely a temporary change in operations for many of these companies, experts see a great growth potential for a permanent shift in some manufacturing sectors. For example, e-commerce and product distribution has increased as people are ordering items online rather than purchasing in stores. Further, the need for remote inspection technology, non-contact sensors, and forms of digital automation is also increasing.

Demand for certain products will also grow post-pandemic.

Many are predicting that businesses will need to install sneeze guard walls inside of offices and other gathering places like gyms, restaurants, and schools to keep people protected. Other forms of medical safety equipment like face shields and masks will also be needed in the near future. Needless to say, there will be opportunities for manufacturers to create new products for the post-pandemic market.

Conclusion

No one knows when things will return to “normal” – but industries that are struggling due to the pandemic cannot sit around and wait. Thankfully, manufacturers are already finding new ways to innovate and produce even during these uncertain times.

Overall, the safety of the people within the manufacturing plant must be every business’s top priority post-pandemic.

Utilizing automation, creating more local jobs, and adopting virtual communication tools will help to create a safer work environment now and for the future. Manufacturers should also be on the lookout for future opportunities to produce products that will be necessary in the post-pandemic world.