The first phase of the Coosa Graphite Processing Facility located in Kellyton is now set to commence; after the board of directors of Westwater Resources Inc., a battery-grade, natural graphite development company, approved $202 million to execute the project.

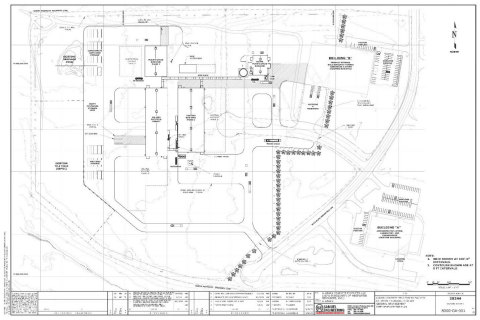

Construction of the Coosa Graphite Processing Facility is expected to begin before the end of 2021 and this future plant is to be developed on a 73 acre site, near Alexander City, located within the Lake Martin Regional Industrial Park. Two buildings which are adjacent to the plant’s site and occupy a total of 90000 square feet, were also purchased to be used as administrative offices, laboratory and warehousing spaces for the project. A subsidiary of Westwater, Alabama Graphite Products LLC, was given approval by the board of directors to purchase the buildings.

Also Read Construction breaks ground on US$529 million levee project in Kansas

The Coosa Graphite Processing Facility is a multi-phase project, which upon completion is intended to purify natural graphite concentrates and manufacture battery ready graphite products. The facility will employ the use of cutting edge technology and processing techniques to carry out the extraction and refining of graphite concentrates with upto 95-97% graphitic carbon (Cg) content which will be used in producing the Coated Spherical Purified Graphite (“CSPG”) for the Li-ion battery anodes. In addition, it will provide jobs for more than 100 people in the area.

The first construction phase of the Coosa Graphite Processing Facility is expected to be completed in early 2023 and also begin processing approximately 8,050 metric tons (mt) per year of graphite concentrate, with the supply of the required feedstock, coming from sources until at least 2028. The facility would be able to produce approximately 3,700 mt of CSPG and 3,800 mt of fine products from SPG milling annually, after the processing and purification processes.

The second phase of the Coosa Graphite Processing Facility is yet to be approved, but the development plans for this phase are focused on increasing the production rate to approximately 35,200 mt per year in 2024. After the processing and purification, the facility would be expected to produce up to 15,800 mt of CSPG and 16,600 mt of fine products from SPG milling annually.

Leave a Reply