Ørsted’s carbon capture and storage facility at the Ørsted Kalundborg CO2 Hub has revealed insights on progress made so far. The first carbon capture and storage value chain project in Denmark has now seen the installation of five sets of column needed for operations at the facility’s hub. These include two at Avedøre Power Station and the remaining at Asnæs Power Station.

The columns play an integral role in the capturing of CO2. Each of the five sets of columns installed by Ørsted at their carbon capture facility at the Ørsted Kalundborg CO2 Hub in Denmark has three main parts, and have been described as the “heart of the site”. Currently, the company is working towards installing connecting pipes for the columns. These will allow for communication with the rest of the plant.

Ørsted Kalundborg CO2 Hub Project Factsheet

Location: Denmark

Developer: Ørsted

Utility: Carbon Capture and Storage (CCS)

Carbon capture technology provider: SLB Capturi

EPC contractor: MT Group

Completion and Operational date: 2026

Annual CO2 capacity: 430,000 tonnes

A look at the five sets of column installed at Ørsted’s CCS facility in Denmark

The columns have a direct contact cooler (DCC). Here, water is directly sprayed to the fuel gas to cool it. The cooled gas now becomes more easier to capture and have its impurities removed.

The other component of the column is the absorber. The cooled fuel gas from the DCC will be passes through a chemically-binding liquid in this part of the column. CO2 is separated from the fuel gas at this point; after-which the CO2-rich liquid is then passes to the third column component for further processing.

The desorber forms the third segment of the column. Here, the CO2-rich liquid is heated. This releases the trapped CO2 gas. The CO2 is then collected and compressed for storage in tanks. Transportation to the Northern Lights storage reservoir in the Norwegian part of the North Sea will then immediately follow suit.

What to expect of Denmark’s first full-scale carbon capture and storage value chain project

The Ørsted Kalundborg CO2 Hub expects completion by 2026. Upon starting operations, Ørsted’s carbon capture and storage facility in Denmark will scrape about 430,000 tonnes of CO2 annually. This has been equated to halting engines of roughly 200,000 petrol-powered cars in Europe in the same time frame.

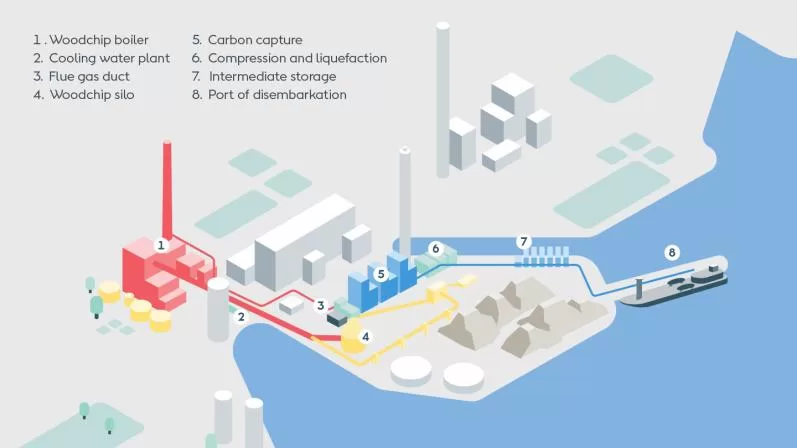

Also of interest is the use of straw- and woodchip as fuel for the heat and power plants implicated in the capture and storage of atmospheric CO2. According to the company, the biomass used at the facility’s plants are waste and residue, instead of fossil fuel. The straw-powered unit, Avedøre Power Station, will handle about 150,000 tonnes of CO2, while the wood-chip powered unit, Asnæs Power Station, handles the remaining 230,000 tonnes.

Activities at the facility in Denmark will cover a 20-year contract awarded to Ørsted Kalundborg CO2 Hub in mid-2023. The Danish Energy Agency made the contract award.

Ole Thomsen, Senior VP and Head of Bioenergy at the company whose vision is a world that runs entirely on green energy had the following to say. “[…] The absorbers, desorbers, and direct contact coolers are essential components that enable the facility to capture and store CO2. With those in place, we’ve taken a great leap forward towards realisation of our project.”

Leave a Reply