Construction on the $6 billion Shell Petrochemicals Complex in Beaver county, Pennsylvania which was originally scheduled to round up last year, got stalled due to the Covid pandemic and this resulted in its delivery date being pushed forward to this year. The plant is intended to produce polythene, an essential commodity required for the manufacture of a wide variety of products which include sports equipment, food packaging, automotive components, containers, and furniture.

Shell Chemical Appalachia is developing its Pennsylvania plant with the goal of producing 1.6 million tonnes per annum (Mtpa) of polyethylene, through the use of low-cost ethane that will be supplied by shale gas producers around the Marcellus and Utica basins. According to the company, the plant’s location in Beaver County is ideal, due to its close proximity to Shell’s customers and the gas supply.

Also Read Construction Updates on Golden Pass Export Terminal in Texas

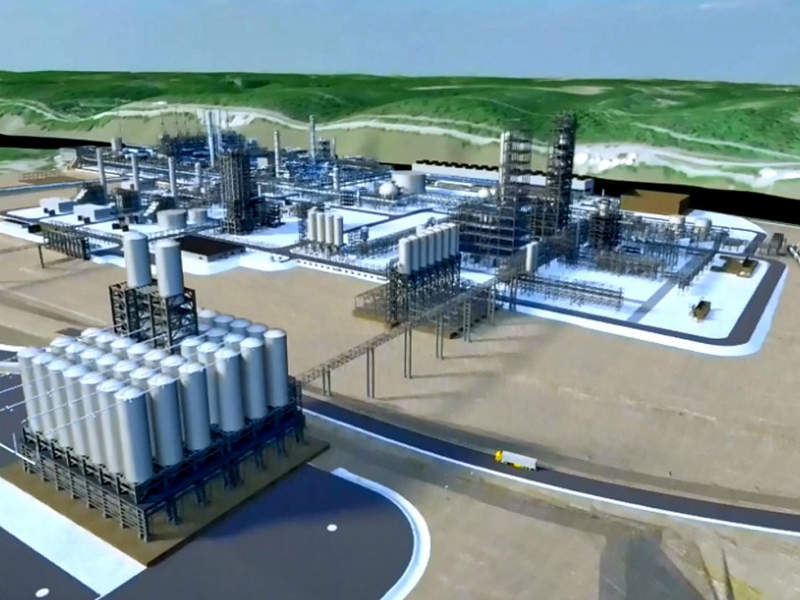

Overview of the Shell Petrochemicals Complex

Construction on the Shell Petrochemicals Complex started in 2016 and the ethane cracker is the largest part of this facility, consisting of a 153km of pipeline and over 200 components . The ethane cracking facility will feature two ethane cracking furnaces, referred to as the seven tail gas and natural gas fired furnaces, with each furnace having a heat input rating of 60 million metric British thermal units (MmBtu) per hour. Low NOx burners are also to be used with the furnaces, which will be controlled via selective catalytic reduction (SCR).

The Shell Petrochemicals Complex will feature various types of infrastructure which include a water treatment plant, laboratory, office building and 250MW natural gas-fired power plant. The power plant is intended to generate the electricity and steam needed for the operations of the Shell complex, but a third of the electricity produced will be also distributed to the local grid. The power plant will make use of three Frame 6B natural gas-fired combustion turbines and each of one will be capable of producing up to 40.6MW of power.

In addition the site of the Shell Petrochemicals Complex will also house three diesel-fired fire pumps, four diesel-fired emergency generator engines, and a 900ft cooling tower, consisting of 28 cell counter-flow mechanical drafts, with a water-flow capacity of 4.44 million gallons per hour.

Contractors working on the Shell Petrochemicals Complex project

The main works contract for construction on the Shell Petrochemicals Complex in Pennsylvania was awarded to Bechtel.

GE Energy was contracted as the supplier of the Frame 6B turbines which will be used for the natural gas-fired power plant, while Flenco Fluid System was subcontracted by GE Energy to handle the supply of auxiliary systems needed for the project.

Leave a Reply