Bearing and wear material manufacturer Vesconite Bearings has placed renewed emphasis on the earthmoving industry with the appointment of Lorraine Deans as industry champion.

Deans has a background in customer service, as well as research in construction.

It is this latter experience, compiling construction project information for a subcontractor bulletin, that particularly drew her to her current role.

“I found out about new projects before construction began,” informs Deans of her previous position.

“This was particularly useful for civil engineers, quantity surveyors and other service providers who wanted to know about projects in the planning phase,” she says.

When Vesconite’s front-line work was streamlined, Deans was asked which industry she had a passion for. The answer was obvious – after years of work in the building and construction, she was keen to return to a familiar industry.

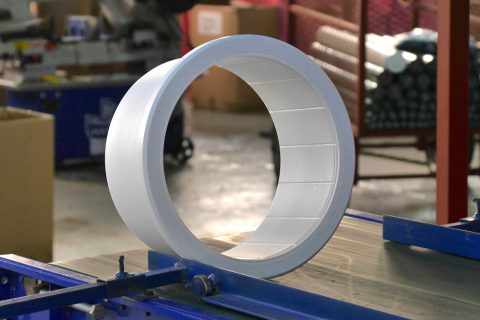

Vesconite’s no-swell wear-resistant self-lubricating bearings, that were developed for the notoriously harsh deep-level South African gold mines, which are characterised by extreme dirt and wet, are also suited to earthmoving, she reasoned.

“Vesconite has an enduring long-life, offers reduced maintenance, reduced shaft wear and is suitable for wet and abrasive environments,” notes Deans.

“It is also particularly valued for its self-greasing ability which provides clients with valuable savings on labour and greasing costs,” she says.

Since her appointment in earthmoving, Deans has introduced herself to present and prospective clients, has become familiar with many of their pain points, and has provided prototypes for some of their most difficult applications.

“We have seen a lot of interest in plain bearings that can be used in suspension systems, oscillating joints and pivot points,” notes Deans.

While testing can take between three and six months, she believes that articulated dump trucks, front loaders, back hoe loaders and grabbers have high potential as applications in which Vesconite will bring considerable savings.

Leave a Reply