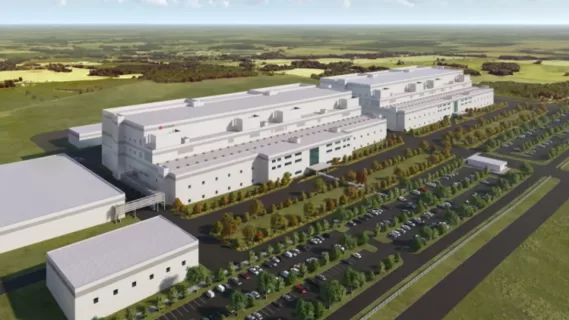

The PowerCo SE Gigafactory Project is a battery cell manufacturing development being implemented in St. Thomas, Ontario, Canada. The project involves an investment of approximately US$7 billion in a large-scale production facility owned by Volkswagen subsidiary PowerCo SE. The gigafactory is planned to have an annual production capacity of up to 90 gigawatt-hours (GWh) at full scale. Construction activities already began with groundworks in progress and major contractors mobilised on site. The facility is scheduled to begin production in 2027.

Infrastructure upgrades in the surrounding region are being carried out in parallel to support the development. Investments are being made in local utilities, road networks, and logistics infrastructure ahead of the main construction phase. Site preparation works have commenced, and the project timeline identifies 2027 as the target for the start of manufacturing operations.

Other than the PowerCo SE Ontario Gigafactory, clean energy in Ontario is gradually being embraced as the PowerBank BESS energy storage also takes shape. PowerBank Corporation expects its 4.99 MW battery storage project in Ontario to commence operations during January 2026. The information was provided through the company’s official statement. The SFF-06 project in Cramehe, Ontario is completing final commission with EVLO. Furthermore, it includes nine battery containers with the project expected to deliver 4.74 MW of daily contract capacity for 251 business days annually.

Project Factsheet

Location: St. Thomas, Ontario, Canada

Investment: Up to €4.8 billion (approx. CAD $7 billion) by 2030

Annual capacity (final expansion phase): Up to 90 GWh

Job creation: Up to 3,000 direct jobs and tens of thousands of indirect jobs

Production start: Targeted 2027

Significance of the project

This project marks a major strategic pivot because the company shifts from vehicle assembly to full-spectrum battery cell production and recycling. By selecting a Canadian site, it taps clean energy, proximity to raw materials and tariff avoidance, aligning with wider investments such as Vianode’s plan to build North America’s first large-scale clean-graphite factory in Ontario. Moreover, the local economy stands to benefit through job creation, supplier spin-offs and increased regional industrial activity. This builds local capabilities and strengthens the ecosystem for electric-vehicle manufacturing.

Beyond those direct effects, the plant adds substantial value for the construction and infrastructure sectors. Its scale means high demand for heavy-civil works, structural steel fabrication, advanced utilities and sustainable building systems. Moreover, as seen in NextStar Energy’s completion of its US$5 billion EV battery plant strengthening the North American supply chain , such large-scale initiatives showcase how industrial projects can transform regional construction capabilities. In addition, the standardised factory design being adopted globally by Volkswagen means lessons learned here will ripple across future megaprojects, improving cost-efficiency and risk-mitigation.

Leave a Reply