In today’s challenging economy, low operating costs and high productivity are essential for business sustainability, the pump industry certainly being no exception. As a global leader in sustainable productivity solutions, Atlas Copco is focused on developing efficient, high performance products in a compact, portable, versatile, durable, and easy-to-service package, a strategy that perfectly aligns to the pump industry.

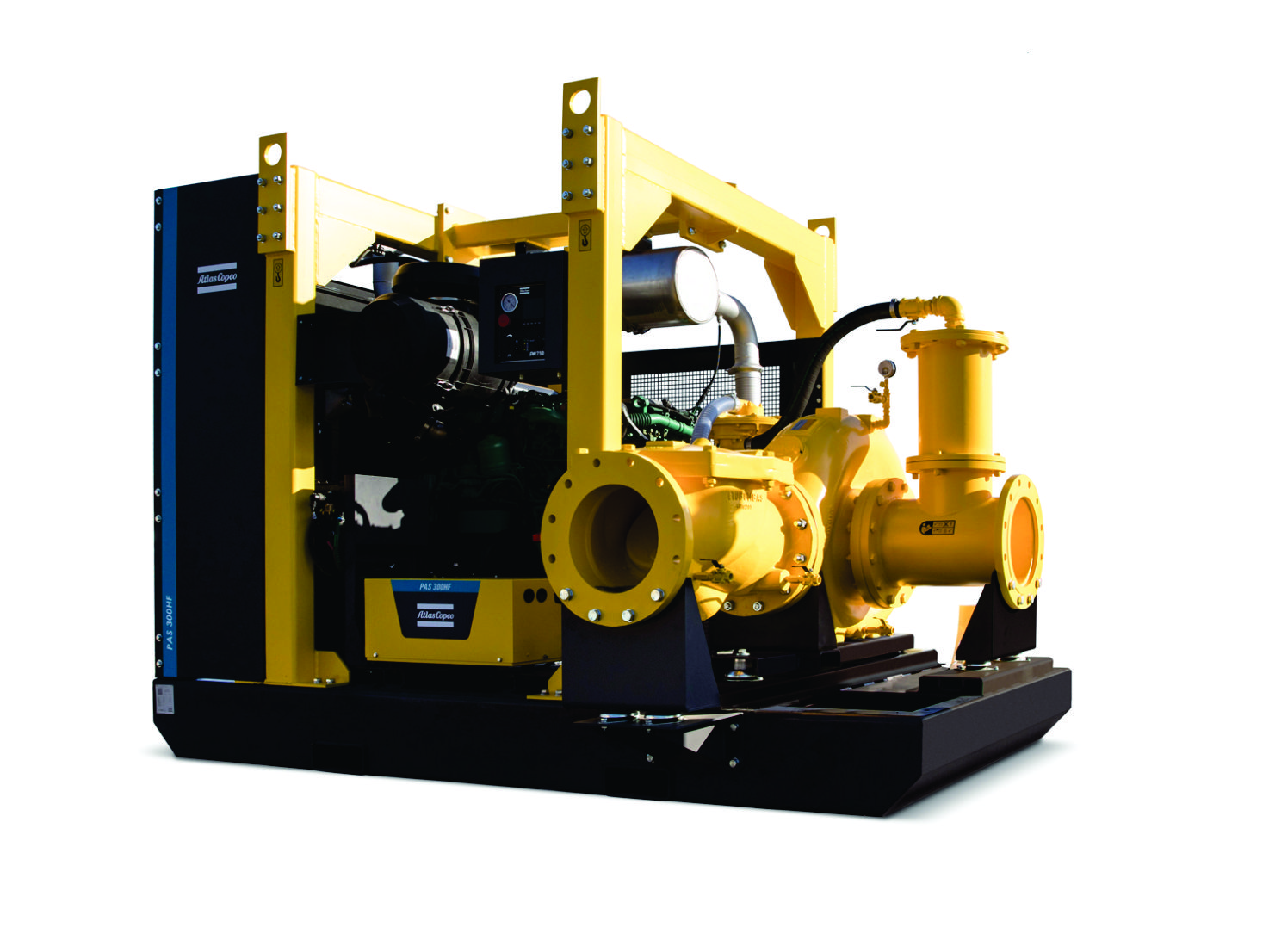

“Our PAS fully automatic dry self-priming centrifugal open-frame pump range serves as a prime example of our commitment to developing smaller, lighter products that are easy to use, move and maintain with an emphasis on versatility to ensure the best solution for dewatering applications,” says Power Technique Business Line Manager, David Stanford.

“These efficient high performance fit-for-purpose pump systems are designed to augment our customers’ businesses while also being considerate to the environment.”

Suitable for transporting or raising water with abrasive solids in suspension, the PAS diesel pump range comprises four high flow (HF) and five medium flow (MF) models delivering a maximum flow capacity of 2100 m3/h, with a maximum head of 75 m and an outlet size of 100 – 300 mm.

The robust PAS pump systems are specially designed and engineered to deliver reliable operation in stringent conditions where start-up can often be a challenge. The pump’s dry prime capabilities allow the end-user to start pumping immediately with a simple flip of the switch.

The PAS pump system is equipped with a high-capacity diaphragm pump for automatic priming; the large SuperDuo separator separates the air in the pump from the liquid which is then sucked by the vacuum pump, making automatic priming possible.

These pumps can work with clean or dirty water and can handle trash and fibrous materials with ease. The inclusion of a centrifugal pump with a semi-open impeller and an abrasion-resistant pump casting ensures an excellent solids handling capability; the system can pump liquids with solids of up to 100 mm in suspension without the risk of clogging.

The PAS range, which is also available in a canopy version, has been tested and verified under the most stringent conditions for reliable performance over a long life span. The robust pumps are suitable for multiple applications typically found in the construction, mining and municipal sectors including general dewatering, wellpoint, floodwater clean-up, stream diversions, sewage bypass and reservoir, pond and canal drainage.

“Efficiency,” says Stanford, “is one of the most essential components for lowest total cost of ownership. “Featuring a high efficiency hydraulic end, our pumps consume very little fuel irrespective of the operating conditions.” In terms of versatility, the modular design means that one pump is capable of covering multiple requirements. Compact dimensions coupled with a light weight facilitate manoeuvrability, keeping downtime to a minimum. “Requiring fewer pumps and increasing productivity contribute positively to the customer’s bottom line,” notes Stanford.

“Service is another valuable contributor to a customer’s profitability,” continues Stanford. “Performed regularly by trained technicians using OEM parts maximises uptime, service will extend the pump system’s life cycle and reduce maintenance costs, all factors that are fundamental to operational efficiency.”

The PAS range is fitted with a hinged cover that provides fast easy, access to components, enabling a three minute clean up and restart. Atlas Copco also offers a number of service packs including Preventive Maintenance Kits, Wear Part Kits, Seal Kits and Gasket or O-Ring kit. Atlas Copco’s high performance long lasting lubricants are especially engineered to match pump maintenance specifications and provide optimal pump protection.

Atlas Copco also supplies a range of VAR wet self-priming centrifugal pumps available in open-frame and canopy versions. Encompassing eleven models, this range features outlet sizes of 40 to 300 mm, a maximum head of 58 m with a maximum flow of 1400 m3/h.