For Concrete Canvas Ltd, the South African market is growing year-on-year. While Geosynthetics are becoming a more commonly considered alternative for projects in the region, over the last year alone, Concrete Canvas Ltd has seen a vast increase in installations within the region’s mining sector.

Concrete Canvas Ltd is the sole manufacturer of the award-winning products, Concrete Canvas (CC) and CC Hydro (CCH). All products are manufactured in their factory in South Wales, UK and is exported to 80+ countries.

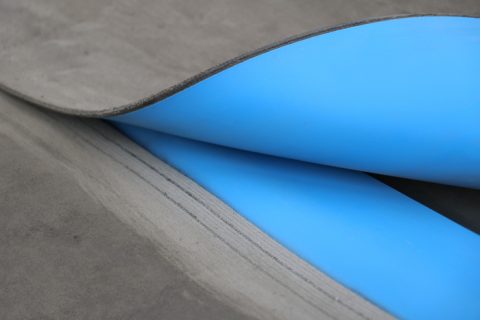

CC is a new material technology called a geosynthetic cementitious composite mat, or GCCM. The material is a flexible concrete impregnated fabric that hardens on hydration to form a thin, durable, water proof concrete layer. Essentially, it’s concrete on a roll.

CCH combines the company’s innovative technology with a highly impermeable, chemically resistant geomembrane liner. The product was specifically developed for use in containment applications.

Both CC and CCH products are used across various applications in the African mining sector, from channel lining to remediation and tank lining.

Products uniqueness

The popularity of CC and CCH products is due to their unique properties, which allow clients and contractors to both address and accommodate common challenges in construction projects in the region’s mining sector – high temperatures, access restrictions, and resources – while providing cost and time savings compared to traditional concreting methods.

CC can be installed using basic hand tools, with no requirement for specialist labour or equipment, while CCH is simply unrolled and thermally welded, with a built-in air channel for accurate on-site testing.

The flexibility of both material variants allows them to be cut to length on site for easier transportation, and accommodate existing assets including concrete infrastructure and pipework.

The use of CC and CCH also eliminates rebound associated with sprayed concrete, and reduces preparation and installation times, while long lead times and curing times typical for traditional methods do not need to be considered. CC can be installed up to 10 times faster than conventional methods and reaches 80% of its total strength within 24 hours of hydration. Inclement weather conditions can also be accommodated, as CC cannot be over-hydrated and therefore allows installation to continue in wet weather.

CC is also recognized as an eco-friendly concrete alternative by the UK’s Environment Agency, which has specified CC for a number of projects in environmentally sensitive areas. The material has a low alkaline reserve and washout rate, eliminating the need to treat runoff, and a lower carbon footprint.

Also, of fundamental benefit is the minimization of Occupational Health and Safety (OHS) risk when using CC and CCH products. With a reduction in plant requirements, labour and time spent on site, comes a resultant OHS risk reduction.

How is the product used?

Currently, there is approximately 50 000sqm of CC being installed across various mining projects in South Africa. Case studies on these should be released in the near future.

The region’s most notable mining project specified 4000m² of an 8mm variant of CCH (CCH8™) to line a gravity thickener tank floor at Exxaro’s Grootegeluk mine in Lephalale, South Africa.

The gravity thickeners play a pivotal role in the recycling of water used for settlement of fines generated through fragmentation and degradation (handling processes in pit and plant; loading of trucks, bunkers, silos, chutes, transfer points). As part of Exxaro’s maintenance programme, it was deemed necessary to remediate each tank to extend their operational life and ensure efficient functioning.

The client has a 3-week window each year in which to carry out maintenance of this nature, and it was essential that treated water be available during this period. As a result, it was decided that one tank would be remediated each year over, ensuring three of the four tanks remained operational during works.

These time constraints and the size of the tank floor area presented further challenges; the conventional solution originally considered – a geomembrane underlay and concrete slab overlay – would be incredibly difficult to complete in three weeks without compromising quality. The temperatures within the tank also often exceed 40°C. As a result, many conventional installation solutions were ruled out.

CC Hydro™ was specified in order to provide a solution which would not be compromised by these factors. CCH8™ would provide the same results as the geomembrane underlay and a 100mm thick concrete slab. Delivered in bulk rolls, simply unrolled and thermally welded, the material was the ideal solution.

Following ground preparation, the CCH8™ bulk rolls were delivered to site and manipulated within the tank in accordance with stringent OHS standards. Once unrolled, cut and positioned, the geomembrane backing was thermally welded and the welds pressure tested, before the material was hydrated and left to set. The 4000m² of the product were installed within 7 days, with no time lost despite a number of significant thunder showers during the installation period.

Outcome

Use of CC Hydro allowed the client to carry out the required works within just one week, compared to the three-week time allocation. The tank was therefore back in use and operational ahead of schedule, saving time and costs for the client. CCH’s unique properties prevented any loss of capacity within the tank, and will provide full impermeability to the tank floor.

We need full technical literature and fob cost per sq.m

1. Does it need well compacted sub base or it has flexibility over the time to adopt shape of sub base when it encounters uneven settlements over the time?

2..what is the thickness

3.. Density

4..Cost per sq.m

5.. want to become sole distributor.