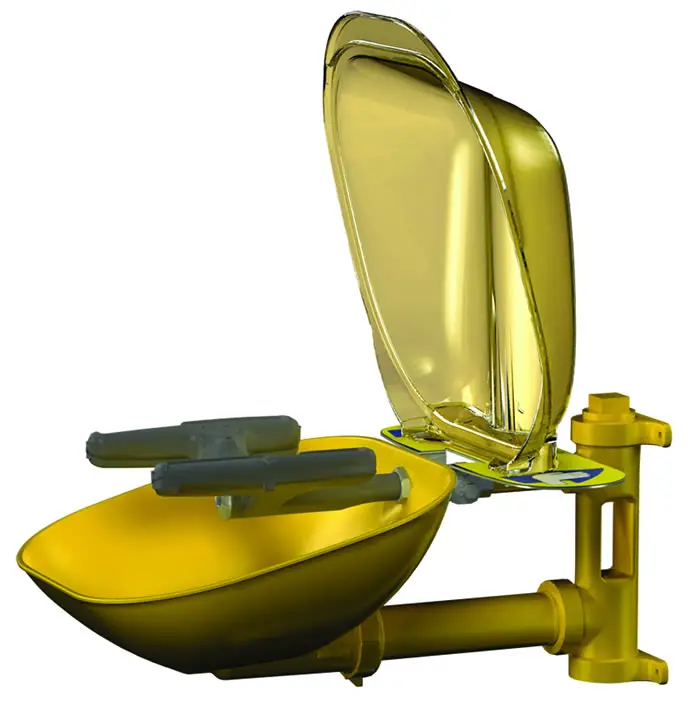

Bradley’s new Halo eye and eye & face wash provides the most washdown facial coverage of any model on the market. The fluid dynamics technology used with HALO works in tandem with a pressure regulated flow control. This directs the flow of water to achieve an all-inclusive spray pattern that quickly washes contaminants from the user’s eyes and face. Based on its superior design, HALO covers 85 percent of the user’s face, which is more than 20 percent better protection than any other eye/face wash on the market. With more coverage and a superior wash pattern, users attain the greatest contaminant relief and protection available.

HALO also incorporates an exclusive self-draining feature, which eliminates standing water left in the unit between uses and testing, reducing the risk of bacteria growth when the unit is not in use.

Halo is also available in a new stainless steel model, which is ideal for caustic work settings such as petrochemical plants, oil refineries or harsh environments with hazardous chemicals. Bradley offers a large variety of preconfigured stainless steel models including wall-mount, pedestal and combination units. When even greater corrosive protection is needed, a heavy-duty 316-stainless steel combination unit model is also available. Barrier-free models are also available.

SpinTec Shower Design Enhances Emergency Shower Performance

Bradley’s new SpinTec showerhead for emergency drench showers delivers a more even distribution of water in less time than competitive models. The innovative SpinTec shower pattern rinses more effectively at a higher velocity, resulting in faster removal of hazardous contaminants from the affected user. SpinTec meets all ANSI and EU standards for emergency drench equipment.

A built-in flow control makes Bradley’s SpinTec as water-efficient as it is effective. Compared to most units with no flow control, SpinTec uses 66% less water. This conserves 150 gallons of water during a 15-minute flush – a significant savings that quickly adds up. The compact showerhead also uses 75 percent less material, which is another “green” benefit of this new technology. Stainless steel SpinTec showerheads are available for highly corrosive environments.

Enclosed Safety Shower Stands Up to Harsh Chemicals and Environmental Conditions

Bradley’s Enclosed Safety Shower, which is armed with an insulated fiberglass structure, fire ratings, and reliable chemical and corrosion resistance, provides superior washdown capability in harsh conditions. The Enclosed Safety Shower withstands harsh chemicals and frigid weather.

Bradley Corp., headquartered in Menomonee Falls, Wis., designs and manufactures emergency safety fixtures, public space plumbing fixtures, tankless water heating systems, washroom accessories, toilet cubicles, and solid plastic lockers. Bradley’s history began 93 years ago with the invention of the washfountain – a revolutionary hand washing fixture designed to improve water flow while saving water and time. Since then, Bradley has developed many innovative products and technologies to help specifiers, engineers and end-users meet goals for facilities and outdoor work environments.

Today, Bradley serves industrial markets worldwide with its full line of innovative emergency eye/face washes and drench showers, including Halo™ Eye and Eye/Face Wash Systems, SpinTec™ drench showers, and enclosed safety showers. All Bradley emergency products are also 3rd party certified and code compliant to the most stringent global standards.