A leading civil and infrastructure engineering contractor installed Vesconite Hilube wear-resistant U-shaped wear pads on graders in Nigeria.

The company found the wear pads operated well with some chiselling wear on the shorter edge of the U-shaped pad after 535 hours of use.

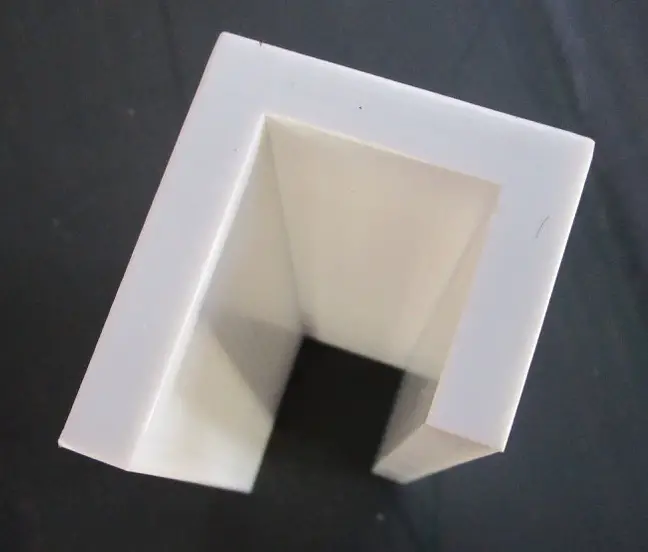

The wear pads acted as guides that were bolted in place on the grader assembly.

The blade assembly, in turn, slid left to right on the guides with the assistance of hydraulic cylinders behind the blade assembly.

The wear pads are essential in the lateral movement of the grader blades, which are responsible primarily for the levelling and shaping of roads and building sites.

Vesconite application engineer Juan van Wyk notes that Vesconite Hilube was particularly useful in this sliding application since it is self-lubricating, so the grader assembly could easily move horizontally for reach in this dirty, inaccessible location, and for the placement of the windrow (built-up road-building material).

Vesconite Hilube was also valued because of its wear properties, since regular placement and movement of the blade was required in often dusty and muddy conditions.

Van Wyk notes that considerable load was placed on the guides of each grader. In addition to the 2,5 ton blade assembly weight distributed over five guides, the blade pushes 2,5 tons of material and is exposed to a cutting resistance of 2,5 tons on the other side of the guide.

Vesconite Hilube wear pads coped well with the considerable compression and tensile strengths that were needed: “There was no distortion under load, even when wet,” Van Wyk says.

The Vesconite Hilube wear pads replaced bronze wear pads of the same U-shaped design, ensuring that the Caterpillar graders, which they were installed on and which are designed for power, performance, reliability and wear-resistance, continued to operate in tough arduous conditions.

Leave a Reply