Vital Engineering offers the market sound advice on design and installation of floor gratings

The choice between fibreglass and steel, and performance versus cost can be bewildering when it comes to installing floor gratings. More often than not, the decision is cost-driven, which can pose a serious threat to safety on site and therefore to the human assets of a company.

Dodds Pringle, Managing Director of Vital Engineering, the leading manufacturer of a broad range of floor gratings, stair treads and safety hand rails, is passionate about educating the market about safety on site in relation to the design and installation of floor gratings.

The company is proud to be the first South African gratings, hand railing and expanded metal manufacturer to obtain an international ISO 9001 design accreditation, and to have held this certification for over 19 years.

“In our experience, the safety of the human asset is unfortunately sometimes the last consideration when purchasing floor gratings. The choice of material that people have to walk on should not be driven by cost, but by many other factors, above all safety. There is not enough knowledge in the market surrounding the importance of gratings,” Pringle maintains.

As specialists in this field, Vital Engineering has decided to step into the breach and provide practical advice to industry on the critical issues of safety, quality and design specifications when it comes to the choice of floor gratings customers should make.

One of the initiatives that the company has taken in creating safety awareness is to distribute a CD to customers detailing the correct gratings installation and performance specifications. The CD provides installation guidelines for the customer, and has been used in the construction site context for induction purposes.

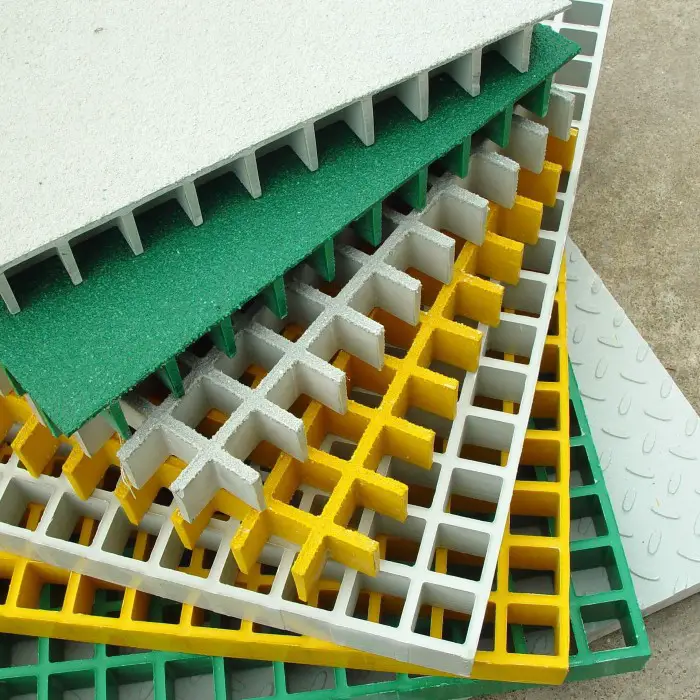

“For example, there needs to be some education to prepare the market for the transition between steel and fibreglass products, and that it is a design issue. These products are not able to take the same load, but then again, each has their own advantages. Our value offering at Vital Engineering is to be a part of the design process in order to guide our customers in ascertaining best performance specifications,” says Pringle.

While fibreglass may recently have become a popular choice in gratings, there is considerable uncertainty about its strength, notes Pringle. This is where design specifications come in, which demand proper research into specific SABS requirements and performance requirements, based on factors such as load and type (harshness) of environment.

“While steel offers more strength than synthetic products, fibreglass is a very robust, low-maintenance product, which reduces the maintenance cycle considerably.These products are best used, amongst other areas, on conveyor walkways, taking into consideration the load-bearing requirements and ensuring that the product is in line with all relevant industry specifications,” says Pringle.

“The risk involved with purchasing gratings according to the lowest price lies in quality and safety specifications not being adhered to,” he emphasises, adding that this can result in other related costs such as injury on site and downtime.

Despite the rising input costs of steel manufacturing in South Africa, Vital Engineering remains committed to sustainability in the industry by refusing to compromise on a quality output, and retaining safety as its focus. The ongoing challenge is the competition the industry faces due to lower prices in the international market.

“Vital Engineering strives to find the most economical solutions for our customers which provide value and quality in the long run. ‘Value-adds’ which we offer our clients include lowering ‘cost of installation’ while increasing maintenance efficiencies. Our input materials are 350WA grade, which offers greater strength than those in a commercial grade material,” says Pringle.

In offering to be a part of the customer’s design process, Vital Engineering runs full checks on load requirements, according to the client’s drawings, in order to ensure compliance from a performance safety point of view, and in relation to SABS requirements.

While the trend is towards cost-driven decision making, as the largest manufacturer and supplier in the gratings sector in South Africa, Vital Engineering considers it of paramount importance to educate the market about the importance of prioritizing safety and performance above cost advantage only.

“We hope that our efforts will help to increase awareness about safety on site, and that looking after human capital should take precedence over cheaper gratings materials of inferior quality, which could prove more costly – on a number of important levels – in the long run,” Pringle concludes.

Leave a Reply